3

1800

900

780

1. Safety precautions

1.3. Before electric work

Caution:

• Be sure to install circuit breakers. If not installed, electric shock may result.

• For the power lines, use standard cables of sufficient capacity. Otherwise, a

short circuit, overheating, or fire may result.

• When installing the power lines, do not apply tension to the cables. If the

connections are loosened, the cables can snap or break and overheating or

fire may result.

1.4. Before starting the test run

Caution:

• Before starting operation, check that all panels, guards and other protective

parts are correctly installed. Rotating, hot, or high voltage parts can cause

injuries.

• Do not touch any switch with wet hands. Electric shock may result.

• Do not touch the refrigerant pipes with bare hands during operation. The

refrigerant pipes are hot or cold depending on the condition of the flowing

refrigerant. If you touch the pipes, burns or frostbite may result.

• Be sure to ground the unit. Do not connect the ground wire to gas or water

pipes, lighting rods, or telephone grounding lines. If the unit is not properly

grounded, electric shock may result.

• Use circuit breakers (ground fault interrupter, isolating switch (+B fuse), and

molded case circuit breaker) with the specified capacity. If the circuit breaker

capacity is larger than the specified capacity, breakdown or fire may result.

• After stopping operation, be sure to wait at least five minutes before turning

off the main power switch. Otherwise, water leakage or breakdown may re-

sult.

1.5. Using R410A refrigerant air conditioners

Caution:

• Use C1220 copper phosphorus, for copper and copper alloy seamless pipes,

to connect the refrigerant pipes. Make sure the insides of the pipes are clean

and do not contain any harmful contaminants such as sulfuric compounds,

oxidants, debris, or dust. Use pipes with the specified thickness. (Refer to

page 7) Note the following if reusing existing pipes that carried R22 refriger-

ant.

• Do not use OL material for the ø22.2 pipes.

- Replace the existing flare nuts and flare the flared sections again.

- Do not use thin pipes. (Refer to page 7)

• Store the pipes to be used during installation indoors and keep both ends of

the pipes sealed until just before brazing. (Leave elbow joints, etc. in their

packaging.) If dust, debris, or moisture enters the refrigerant lines, oil dete-

rioration or compressor breakdown may result.

• Use ester oil, ether oil, alkylbenzene oil (small amount) as the refrigeration oil

applied to the flared sections. If mineral oil is mixed in the refrigeration oil, oil

deterioration may result.

• Do not use refrigerant other than R410A refrigerant. If another refrigerant is

used, the chlorine will cause the oil to deteriorate.

• Use the following tools specifically designed for use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant. Contact your

nearest dealer for any questions.

Tools (for R410A)

Gauge manifold

Flare tool

Charge hose

Size adjustment gauge

Gas leak detector

Vacuum pump adapter

Torque wrench

Electronic refrigerant charging scale

Safety chager

• Be sure to use the correct tools. If dust, debris, or moisture enters the refrig-

erant lines, refrigeration oil deterioration may result.

• Do not use a charging cylinder. If a charging cylinder is used, the composi-

tion of the refrigerant will change and the efficiency will be lowered.

1.6. Accessories of outdoor unit (Fig. 1-1)

The parts show in the left are the accessories of this unit, which are affixed to the

inside of the service panel.

1

Flange joint ...

×

1

2

Packing .........

×

1

2. Installation location

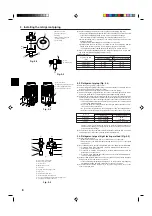

2.1. Refrigerant pipe (Fig. 2-1)

s

Check that the difference between the heights of the indoor and outdoor

units, the length of refrigerant pipe, and the number of bends in the pipe are

within the limits shown below.

Models

A

Pipe size (mm)

B

Pipe length

C

Height

D

Number of

Gas side Liquid side

(one way)

difference

bends (one way)

RP8

ø25.4

ø9.52

Max. 80 m

Max. 40 m

Max. of 15

RP10

ø28.58

ø12.7

Max. 80 m

Max. 40 m

Max. of 15

• Height difference limitations are binding regardless of which unit, indoor or outdoor,

is positioned higher.

E

Indoor unit

F

Outdoor unit

2.2. Choosing the outdoor unit installation location

• Avoid locations exposed to direct sunlight or other sources of heat.

• Select a location from which noise emitted by the unit will not inconvenience

neighbors.

• Avoid locations where the unit will be exposed to strong winds.

• Select a location permitting easy wiring and pipe access to the power source and

indoor unit.

• Avoid locations where combustible gases may leak, be produced, flow, or accumulate.

• Note that water may drain from the unit during operation.

• Select a level location that can bear the weight and vibration of the unit.

• Avoid locations where the unit can be covered by snow. In areas where heavy snow

fall is anticipated, special precautions such as raising the installation location or

installing a hood on the air intake and air outlet must be taken to prevent the snow

from blocking the air intake or blowing directly against it. This can reduce the airflow

and a malfunction may result.

• Avoid locations exposed to oil, steam, or sulfuric gas.

2.3. Outline dimensions (Outdoor unit) (Fig. 2-2)

E

F

D

C

B

A

Fig. 2-1

Fig. 2-2

Fig. 1-1

1

2

(mm)