Machining Samples

Machining Samples

Revolutionizing product creation with high-performance machining

required for future generations

Product Line-up

Functions and

F

eatures

Intelligent A

T

Opt Dr

iv

e System

Long Lif

e System

Pow

er Supply

, Control Specifications

Machine Installation

Machining Samples

Precise Finish Circuit

Natur

al User Interf

ace

AD

VANCE PLUS control

Options

7

8

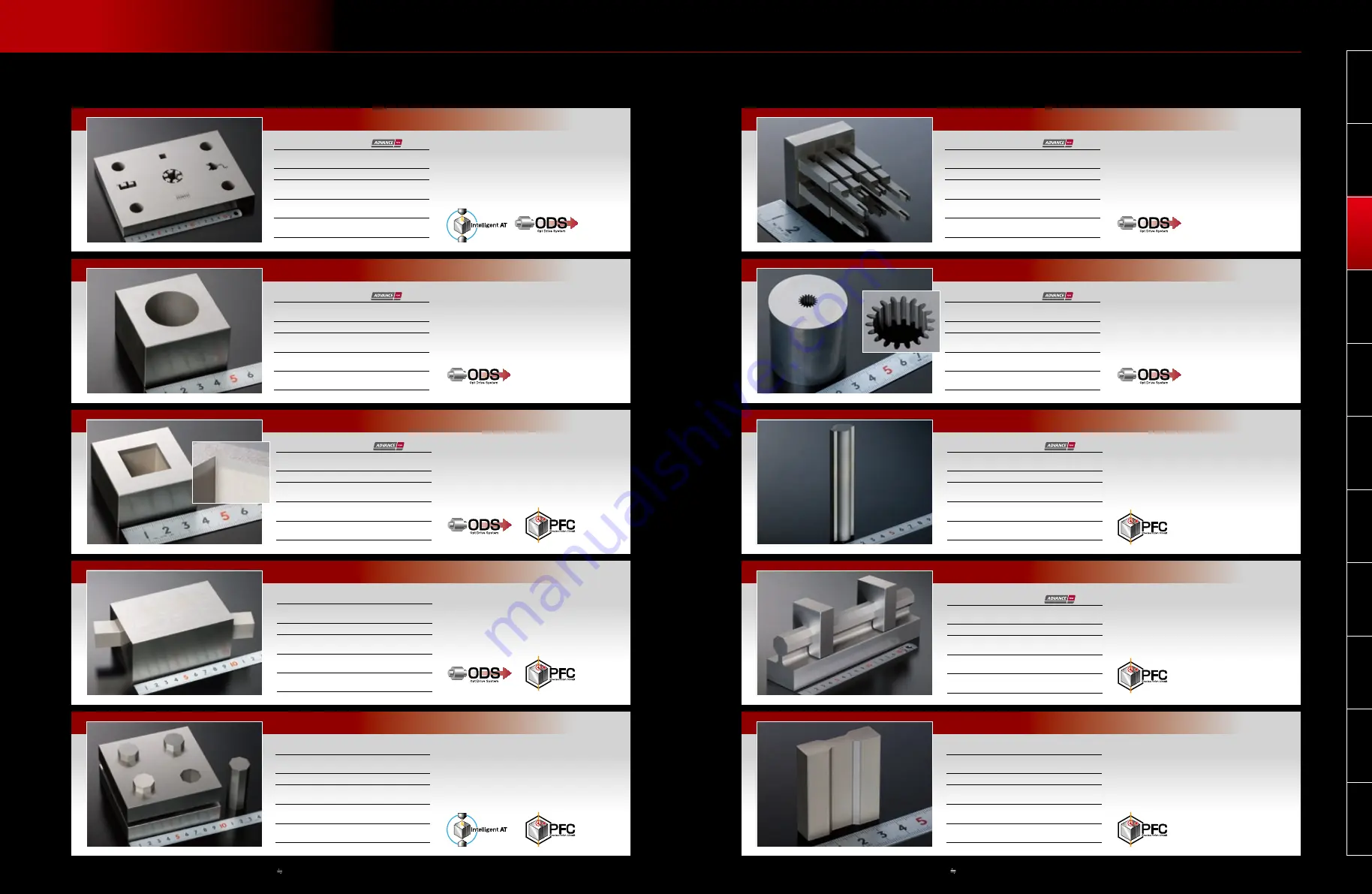

Highly accurate pitch machining

Circular machining

•

Stable automatic threading is realized using

Intelligent AT during multi-shape machining

•

Highly accurate machining is possible using

ODS

•

Thick workpieces can be machined with high

straight-line accuracy using ODS

•

High-speed and precise straight machining

are realized using PFC

•

Circular accuracy is improved using ODS

•

Bumps or undercuts at the approach point

are suppressed, attaining precise circular

cuts

•

Stable automatic threading is realized using

Intelligent AT during multi-shape machining

•

Productivity is improved by reducing

machining time using PFC

•

Highly accurate machining is possible using

ODS

•

Improved taper accuracy using PFC creates

uniform cutting edge lengths

•

Highly accurate machining is possible using

ODS

•

A machining accuracy of ±3µm is realized for

high L/D machining of pin widths from 1.0 to

4.5mm and a length of 40mm

•

High-speed and precise straight machining

are possible using PFC

•

A straight-line accuracy within 5µm is

possible even with a 200mm-thick workpiece

•

Highly accurate machining is possible using

ODS

•

New corner machining control (CM3)

improves shape accuracy to within ±2µm

under nozzle release conditions

•

High-speed and highly accurate machining

are possible using PFC

•

High-grade machining of special materials

(e.g., titanium, graphite, PCD)is realized

using a standard V power-supply

•

High-speed and precise straight machining

are possible using PFC

•

High-performance realized for tungsten

carbide punch machining

Model

Electrode

material

Workpiece

Workpiece

thickness

Surface

roughness

Machining

accuracy

MV2400R

ø0.2

(.008")

/BS

Steel(PD613)

20mm

(.787")

Rz2.5µm/Ra0.32µm

Pitch ±2µm

MV1200R

ø0.2

(.008")

/BS

Steel(SKD11)

20mm

(.787")

Rz2.5µm/Ra0.32µm

±3µm

MV2400S

Die

:ø0.20

(.008")

/BS

Punch :ø0.25

(.010")

/BS

Steel(SKD11)

Die

:100mm

(3.9")

Punch :150mm

(5.9")

Rz3.5µm/Ra0.45µm

±5µm

MV1200S

ø0.2

(.008")

/BS

Steel(SKD11)

Die

:20mm

(.78")

Punch :50mm

(1.97")

Rz2.0µm/Ra0.28µm

±3µm

Model

Electrode

material

Workpiece

Workpiece

thickness

Surface

roughness

Machining

accuracy

MV1200R

ø0.2

(.008")

/BS

Steel(SKD11)

30mm

(1.181")

Rz2.0µm/Ra0.28µm

Roundness 2.0µm

Model

Electrode

material

Workpiece

Workpiece

thickness

Surface

roughness

Machining

accuracy

Model

Electrode

material

Workpiece

Workpiece

thickness

Surface

roughness

Machining

accuracy

Model

Electrode

material

Workpiece

Workpiece

thickness

Surface

roughness

Machining

accuracy

Model

Electrode

material

Workpiece

Workpiece

thickness

Surface

roughness

Machining

accuracy

MV1200R

ø0.2

(.008")

/BS

Steel(SKD11)

4~25mm

(0.16~0.98")

Rz3.1µm/Ra0.38µm

±3µm

MV2400R

ø0.2

(.008")

/BS

Tungsten carbide (G5)

100mm

(3.9")

Rz2.2µm/Ra0.3µm

±4µm

MV1200S

ø0.2

(.008")

/BS

Titanium alloy

40mm

(1.6")

Rz2.2µm/Ra0.28µm

±5µm

Model

Electrode

material

Workpiece

Workpiece

thickness

Surface

roughness

Machining

accuracy

MV1200R

ø0.1

(.004")

/BS

Steel(SKD11)

5mm

(.197")

Rz2.0µm/Ra0.26µm

±2µm

Model

Electrode

material

Workpiece

Workpiece

thickness

Surface

roughness

Machining

accuracy

MV2400S

ø0.25

(.010")

/BS

Steel(SKD11)

200mm

(7.9")

Rz4.8µm/Ra0.71µm

±3µm

Model

Electrode

material

Workpiece

Workpiece

thickness

Surface

roughness

Machining

accuracy

Model

Electrode

material

Workpiece

Workpiece

thickness

Surface

roughness

Machining

accuracy

Cutting edge machining

Fit machining

Slide core

* The listed machining results are all based on in-house conditions and measurements.

(Note) JIS B0601: '01 and ISO 4287: '97/ISO 1302: '02 compliant (Rz

conventional notation Ry)

* The listed machining results are all based on in-house conditions and measurements.

(Note) JIS B0601: '01 and ISO 4287: '97/ISO 1302: '02 compliant (Rz conventional notation Ry)

Connector machining

Gear machining

Thick workpiece machining (tungsten carbide)

Thick workpiece machining

Parts machining