Precise Finish Circuit

Improved productivity

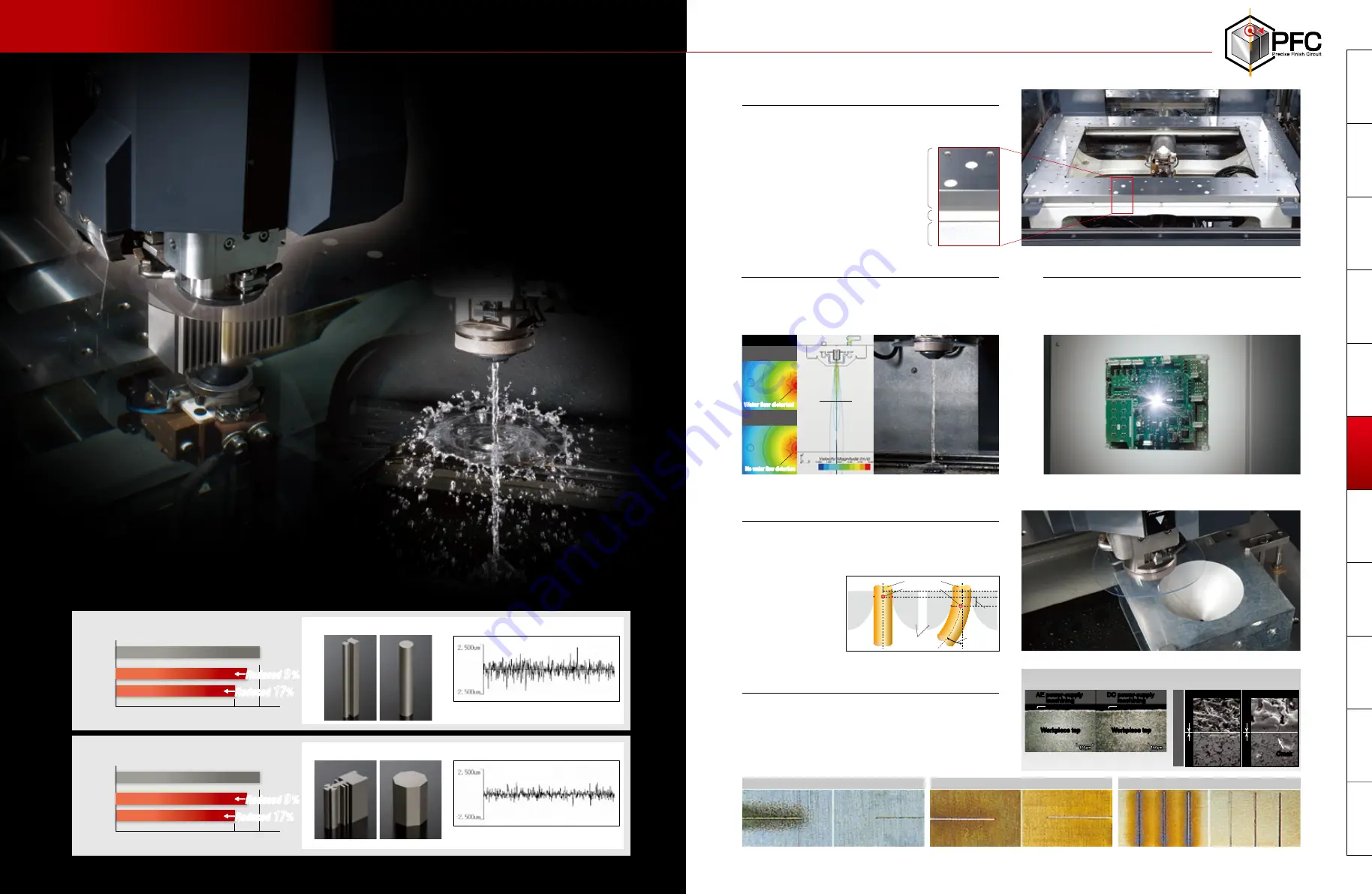

High-speed machining has been enhanced by newly improved power-supply

performance for multi-pass type jobs

工作物表面の酸化

Comparison of AE and DC

power-supply machining

Comparison of water- and

oil- machined surfaces

AE power-supply

machining

DC power-supply

machining

Table insulation

High-accuracy taper machining

using round dies

●

Highly accurate machining of extremely small tapered

sections is realized

●

Uniform die edge land cuts are possible

●

Angle Master Function realizes highly accurate machining of

large tapered sections

●

Insulated worktable ensures improved surface finishing

●

Stable machining realized when using short-pulse and

low-voltage machining conditions

Machining time comparison for Rz3.5µm with 3 cuts

0

100

(%)

Machining samples

Machining time comparison for Rz2.0µm with 4 cuts

Wide range of technologies for ever-changing working environments

Hardened

table

Ceramic

Casting

Wire guide

●

Flow analysis simulation was used to optimize the water

flow through the guide, enhancing cutting speed by

improving sludge removal from the gap

High-speed digital control

●

Spark detection speed (up to twice as fast as our

conventional model) provides improved discharge

efficiency and suppresses wire breakage simultaneously

while improving machining speed

,

Reduced

17

%

,

Reduced

17

%

,

Reduced

17

%

,

Reduced

17

%

,

Reduced

9

%

,

Reduced

9

%

,

Reduced

9

%

,

Reduced

9

%

Water flow distorted

Water flow distorted

No water flow distortion

No water flow distortion

Non-optimized

wire guide structure

Non-optimized

wire guide structure

Optimized wire

guide structure

Optimized wire

guide structure

Angle deviation point

Diamond die

Accurate angle

Wire electrode

Specification

value

compensation

0

100

(%)

Wire electrode : ø0.2

(.008")

/BS

Workpiece

: Steel(SDK11), t60mm

(2.4")

Wire electrode : ø0.2

(.008")

/BS

Workpiece

: Steel(SDK11), t20mm

(0.8")

A-A cross-section

A-A cross-section

↑

A

↑

A

*Angle Master guide kit

is optional

*Max. taper angle is 45°

(at max. 40

(1.6")

mm)

Oil machining

Water machining

Crack

Crack

* Photo shows a comparison under adverse

conditions where electrolysis occurs easily

DC power-supply

machining

AE power-supply

machining

Titanium alloy

DC power-supply

machining

Brass

AE power-supply

machining

Aluminum

AE power-supply

machining

AE power-supply

machining

Workpiece top

Workpiece top

Workpiece top

Workpiece top

Machined surface

Machined surface

DC power-supply

machining

DC power-supply

machining

High-speed anti-electrolysis power supply

(AE power supply)

●

Electrolytic corrosion is suppressed, preventing the

formation of soft layers

●

Compatible with all power circuits, from rough machining to

finish machining

●

High-speed, safe unmanned machining possible using water

Machined surface

Machined surface

Edge

Machined surface

Machined

cross-section

Machined surface

Machined

cross-section

Conventional

model

MV-R

MV-S

Conventional

model

MV-R

MV-S

*Compared to conventional Mitsubishi Electric Wire-cut EDM (FA Series)

*Compared to conventional Mitsubishi Electric Wire-cut EDM (FA Series)

Machining samples

Surface roughness

Surface roughness

Product Line-up

Functions and

F

eatures

Intelligent A

T

Opt Dr

iv

e System

Long Lif

e System

Pow

er Supply

, Control Specifications

Machine Installation

Machining Samples

Precise Finish Circuit

Natur

al User Interf

ace

AD

VANCE PLUS control

Options

13

14