Natural User Interface

Easy operation

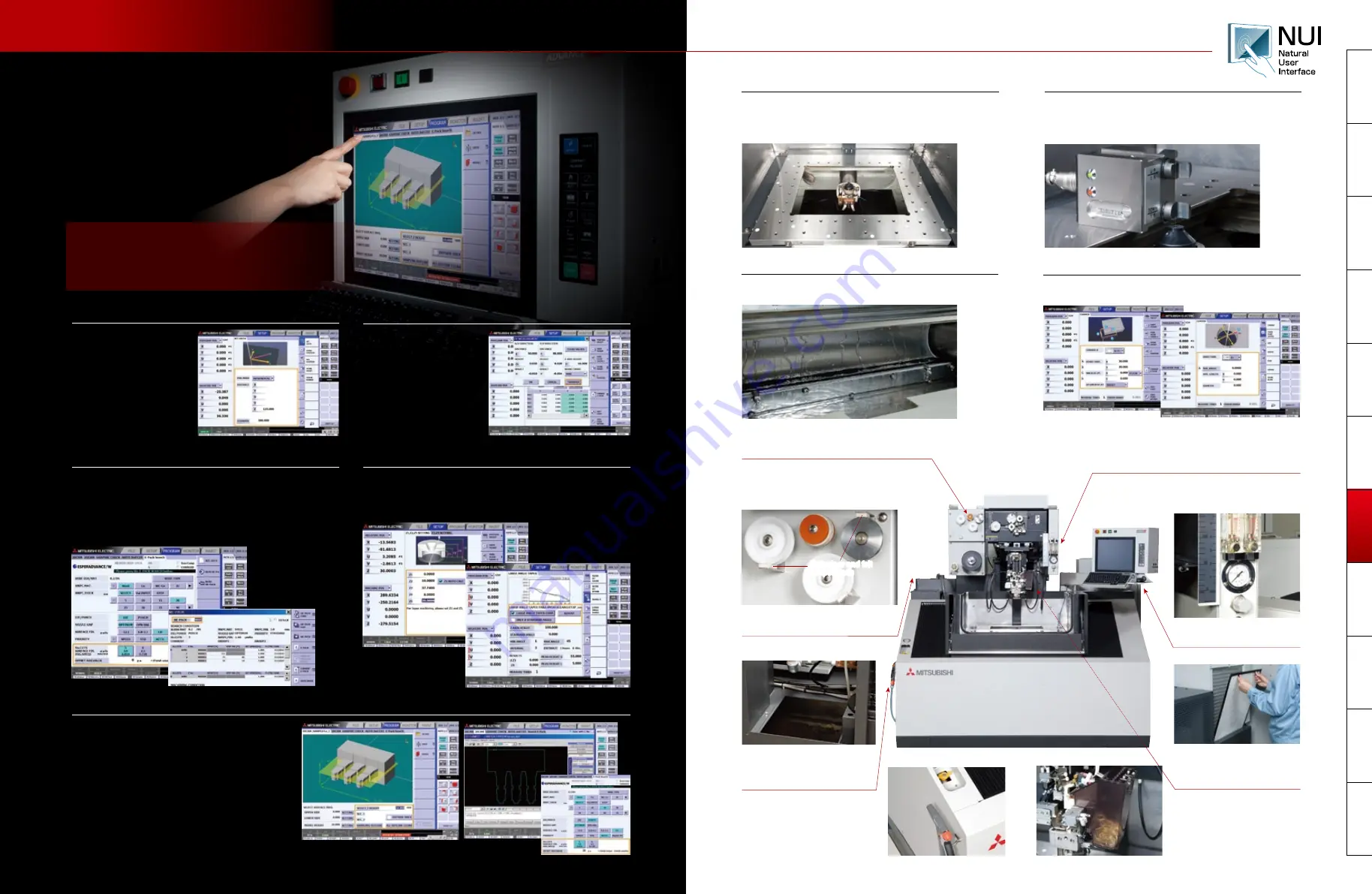

Wire travel system

●

A large access window into the fluid

tank provides easy entry for cleaning

Dielectric fluid supply unit

●

Chiller air filter

Unit cooler filter

User-friendly features ensure easy operation

●

Reads and displays 3D CAD data (Parasolid

format *

1

) with a built-in 3D CAM

●

Extracts 3D model contours with a built-in 3D CAM

●

Creates NC data, including machining conditions,

with a built-in 2D CAM

●

Automatic ME-pack insertion into the 2D CAM path

●

Analyzes shape features for improved machining

performance with a 3D-PM

Advanced 3D data for machine control

*1 Parasolid is a registered trademark of UGS PLM Solutions Co., Ltd.

High-accuracy taper machining

(Angle Master)

Machining condition search function

●

Interactive operation easily creates NC data with machining

condition

●

Job scheduling adjustment uses the schedule call back,

extra job insertion and ME-pack feature

*ME-pack is a package of machining processes including offset, machining

speed and adaptive control setting

Work alignment function

●

By measuring the

workpiece flatness with a

dial indicator, the wire tilt

can be automatically

compensated to match

the angle of the part

This reduces further

set-up time

Set-up screen

●

Outstanding graphics

provides easy operation

Ergonomic design

●

User-friendly keyboard and mouse

●

Easy-to-view screen (15-inch)

●

Intuitive operations using touch-panel control

●

Easily read the filter pressure

●

The convenient location of the

jet cleaning nozzle makes

tank clean-up easy

Filter pressure gauge

and jet cleaning nozzle

●

Conveniently located in

front for easy maintenance

Broken wire

collection box

Precise positioning

●

Highly accurate workpiece pick-up positioning is possible

with the water flow on or when a workpiece is submerged

Hardened table and all stainless-steel structure

●

Equipped with a hardened table

●

The working tank and dielectric supply unit are made of

stainless-steel

●

Resistant to deterioration by dielectric fluid and sludge

●

The stability of the wire tensioning system

is improved by a felt wiper and felt keeper

pads that eliminate the chance of the wire

jumping off the rollers

Felt wiper and felt

keeper pads

Dielectric fluid flow meter and

jet flow adjustment valve

●

Dielectric flow meters are easy to read

●

The adjustable jet flow valve increases the

range of work that can be done

●

Highly accurate wire alignment is easy using the

wire-alignment device (optional)

●

Taper parameter set-up is simple using the

wire-alignment device

Wire alignment

Cleaning mechanism

<MV2400R/S>

●

A forced-flush self-cleaning mechanism prevents sludge

from sticking to the stainless-steel seal plate

●

Angle Master function realizes precise machining of large

tapered angles

●

Optimum taper specifications are automatically set to match

the wire electrode angle

Product Line-up

Functions and

F

eatures

Intelligent A

T

Opt Dr

iv

e System

Long Lif

e System

Pow

er Supply

, Control Specifications

Machine Installation

Machining Samples

Precise Finish Circuit

Natur

al User Interf

ace

AD

VANCE PLUS control

Options

15

16