9

5

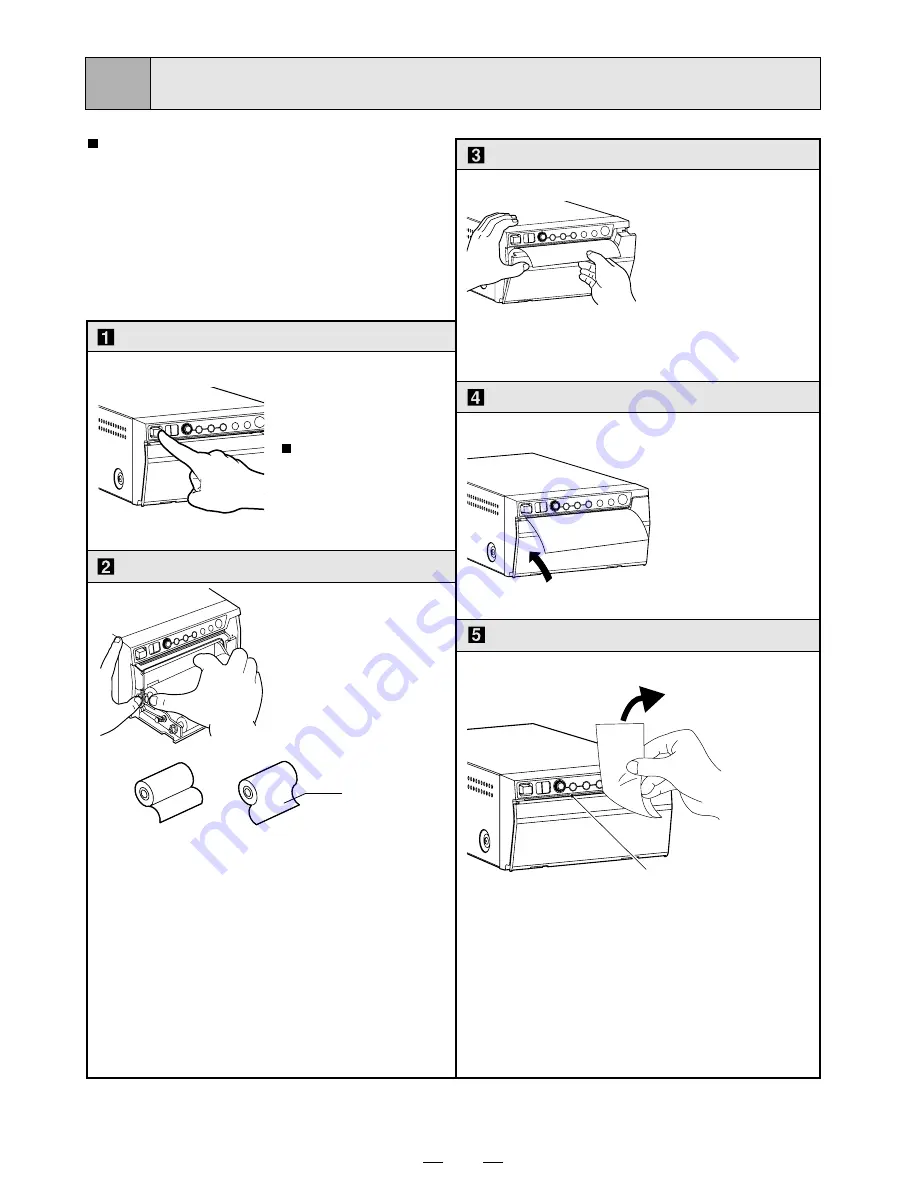

INSTALLATION OF PAPER

Moisture,

fi

ngerprints or dust on

the paper surface may cause a

noise at printing or deterioration

in print quality. Set the paper by

the following procedure to prevent

adhesion of

fi

ngerprint or dust on

the paper surface.

Note:

The printing surface is the outside.

Place the paper with the thermsen-

sitive side (printing side) up.

When the paper roll is placed in-

versely, images can not be printed.

•

Press the

OPEN

button.

The door opens.

printing side

• Place the paper roll

in the printer.

Load the paper roll.

Open the door.

• Pull out the

fi

rst 15-

20cm (6 in. - 9 in.)

of the paper to

remove any slack

in the roll.

Pull out the paper end.

Close the door.

Cut the paper end.

•

Cut the paper end with the cutter by

pulling the paper upwards against the

cutter blade.

CORRECT

INCORRECT

cutter

Summary of Contents for P-95DW

Page 2: ......