- 99 -

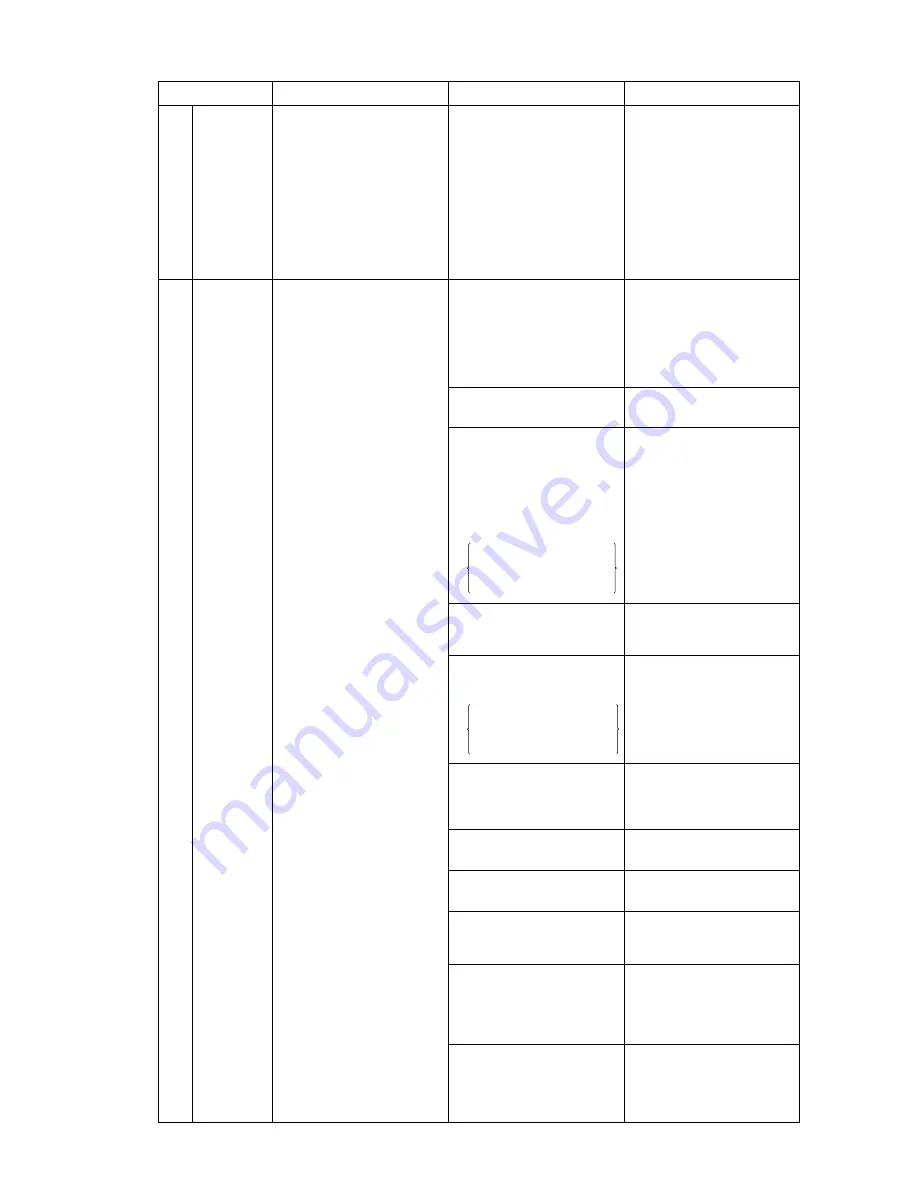

Checking code

1301

Meaning, detecting method

Cause

Checking method & Countermeasure

Low pressure

abnoramlity

When starting the compressor

from Stop Mode for the first time

(include the time when starting

the compressor for the next time,

when starting bound power,

ending bound power or when

the thermo turns off just after

the remote controller is turned

on), check the low-pressure

sensor beforehand. If the sensor

is 0.098MPa, stop the operation

immediately after starting.

(1) Internal pressure is dropping

due to a gas leak.

(2) The low pressure pressure

sensor is defective.

(3) Insulation is torn.

(4) A pin is missing in the

connector, or there is faulty

contact.

(5) A wire is disconnected.

(6) The control board’s low

pressure pressure sensor

input circuit is defective.

Refer to the item on judging low

pressure pressure sensor failure.

1302 High pressure

abnoramlity 1

(Outdoor unit)

1. When pressure sensor

detects 3.87MPa or more

during operations (the first

time), outdoor unit stops once,

mode is changed to restart

mode after 3 minutes, then

the outdoor unit restarts.

2. When a pressure of 3.87MPa

or more is detected again (the

second time) within 30

minutes after first stop of

outdoor unit, mode is

changed to restart mode after

3 minutes, then the outdoor

unit restarts.

3. When 3.87MPa or more

pressure is detected again

(the third time) within 30

minutes after stop of outdoor

unit, error stop is observed

with code No. “1302”

displayed.

4. When 3.87MPa or more

pressure is detected 30 or

more minutes after stop of

outdoor unit, the detection is

regarded as the first time and

the process shown in 1. is

observed.

5. 30 minutes after stop of

outdoor unit is intermittent

fault check period with LED

displayed.

6. Error stop is observed

immediately when pressure

switch (4.15 MPa) operates

in addition to pressure sensor.

(1) Poor operations of indoor

LEV

→

Heating

(2) Poor operations of ball valve.

(3) Short cycle of indoor unit.

(4) Clogging of indoor unit filter.

(5) Fall in air volume caused by

dust on indoor unit fan.

(6) Dust on indoor unit heat

exchanger.

(7) Indoor unit fan block, motor

trouble.

(2)~(7) : Rise in high pressure

caused by lowered condensing

capacity in heating-only and

heating-main operation.

(8) Short cycle of outdoor unit.

(9) Dust on outdoor unit heat

exchanger.

(10) Outdoor unit fan block,

motor trouble, poor

operations of fan controller.

(8)~(10) : Rise in high pressure

caused by lowered condensing

capacity in cooling-only and

cooling-main operation.

(11) Poor operations of solenoid

valves SV1 (Bypass valves

(SV1) can not control rise

in high pressure).

(12) Thermistor trouble

(TH5, TH6).

(13) Pressure sensor trouble.

(14) Control circuit board

thermistor trouble, pressure

sensor input circuit trouble.

(15) Thermistor mounting failure

(TH5, TH6)

(16) No connector for pressure

switch (63H), disconnected

wire.

(17) Fuse melting on the control

board (F01 or F02).

Check operations status by

actually performing cooling or

heating operations.

Heating : Indoor LEV

See

Trouble check of LEV and

solenoid valve.

Confirm that ball valve is fully

opened.

Check indoor unit and take

measures to trouble.

Check outdoor unit and take

measures to trouble.

Check outdoor unit fan

See

Trouble check of outdoor

unit fan.

See

Trouble check of solenoid

valve.

Check resistance of thermistor.

Check

Trouble check of

pressure sensor.

Check inlet temperature and

pressure of sensor with LED

monitor.

Check inlet temperature and

pressure of sensor with LED

monitor.

Check whether the fuse melts.

Check whether the actuator for

the cooling FAN (MF), the 4-way

valve or the solenoid valve is not

short-circuited and broken.

+0

-1.5