a.

Replace only the compressor

if only the compressor is found to be defective.

(Overcurrent will flow through the inverter if the compressor is damaged, however, the power supply is automatically

cut when overcurrent is detected, protecting the inverter from damage.)

b. Replace the defective components if the inverter is found to be defective.

c. If both the compressor and the inverter are found to be defective, replace the defective component(s) of both devices.

(1) Inverter related defect identification and countermeasures

a. Check the breaker capacity.

b. Electrical system short circuit or grounding other than the inverter

c. Refer to (3) - [1] if not a, or b.

a. Earth leakage breaker capacity/sensitivity current check

b. Meg defect for electrical system other than the inverter

c. Refer to (3) - [1] if not a, or b.

• Check the inverter frequency at the LED monitor and proceed

to (2) - [3] if the status is operational.

Go to (2) - [3].

a. Check to ensure that power supply wiring, etc. of the periph-

eral device is not in close contact with the power supply wiring

of outdoor unit.

b. Check to ensure that the inverter output wiring is not in close

contact with the power supply wiring and transmission lines.

c. Check to ensure that the transmission line shield wiring is being

used properly in the necessary environment, and that the shield

wire ground is appropriate.

d. Meg defect for electrical system other than the inverter.

e. Attach a ferrite core to the inverter output wiring. (Please con-

tact the factory for details of the service part settings.)

f. Change the power to another system.

g. If this problem occurs suddenly, there is a possibility that the

inverter output is grounded. Proceed to (2) - [3].

• Contact the factory for cases other than those listed above.

a. Check to ensure that the unit is grounded.

b. Check to ensure that the transmission line shield wiring is be-

ing used properly in the necessary environment, and that the

shield wire ground is appropriate.

c. Check to ensure that the neither the transmission line or ex-

ternal connection wiring run close to another power supply

system or run through the same conduct pipe.

• Contact the factory for cases other than those listed above.

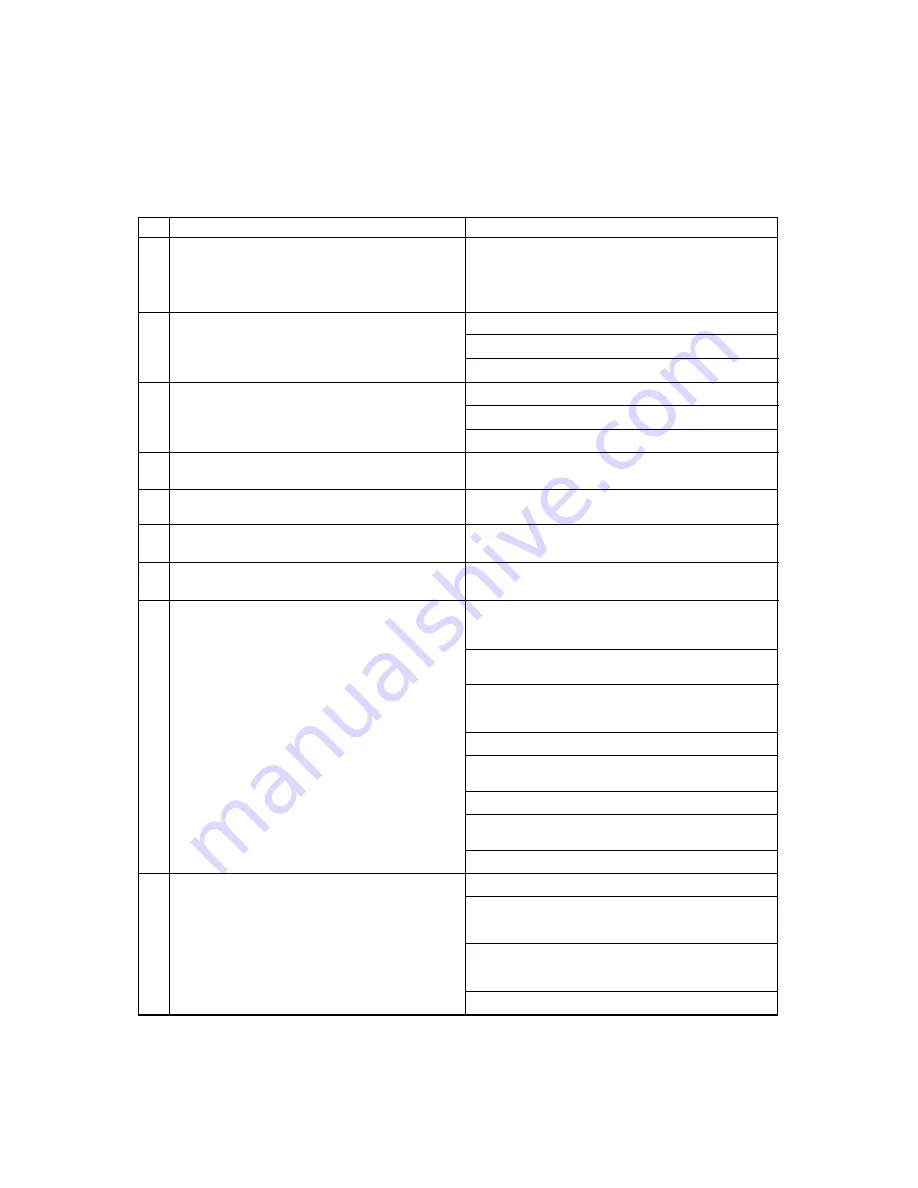

Error display/failure condition

Measure/inspection item

[1]

[2]

[3]

[4]

[5]

[8]

[9]

Inverter related errors

4250, 4255, 4220, 4225, 4230, 4235, 4240, 4245, 4260,

4265, 5301, 0403, 5110

Main power breaker trip

Main power earth leakage breaker trip

Only the compressor does not operate.

• Check the inverter frequency at the LED monitor and proceed

to (2)-[6], [7] if status is operational.

[6]

Only the fan motor does not operate.

The compressor always vibrates strongly or emits an

abnormal noise.

Noise has penetrated the peripheral device

Sudden malfunction

(as a result of external noise.)

Notes: 1. Due to a large capacity electrolytic capacitor used in the inverter, voltage still flows through even after cutting the main power,

creating the possibility of electric shock. As a result, wait for a sufficient length of time (5~10 minutes) after cutting the main power

and check the voltage at both terminals of the electrolytic capacitor to performing any checks on the inverter.

• Check the inverter frequency at the LED monitor and proceed

to (2)-[6], [7] if status is operational.

[7]

The fan motor shakes violently at all times or makes an

abnormal sound.

2. Damage will result to the components of IPM, etc. if the inverter wiring is not properly secured with screws, or if the connector has

not been properly inserted. It is likely that any errors occurring after replacing components are the result of wiring mistakes.

Ensure that the wiring, screws, connectors and Faston, etc. are properly inserted.

3. Do not remove or insert inverter connectors with the main power supply on, as this will result in damage to the PCB.

4. The current sensor will be damaged if current flows without connecting to the PCB. Always insert connectors into the correspond-

ing PCB when running the inverter.

Check the details of the inverter error in the error log at

9

.[1]

Check Code List.

Perform the measures corresponding to the error code and error

details determined using

9

.[2] Responding to Error Display on

the Remote Controller.

- 142 -

6. Inverter and compressor