5

6. Installation/Wiring work

4

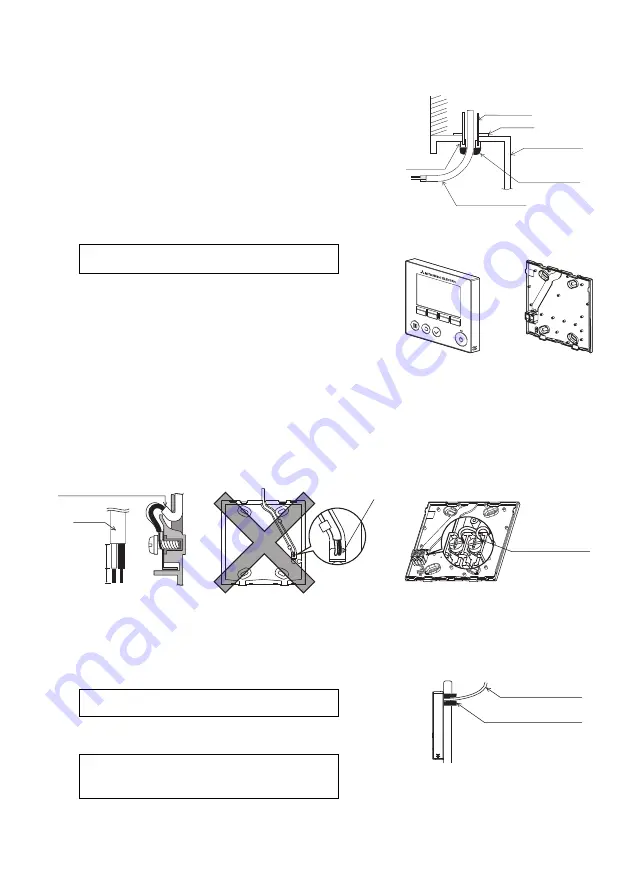

Connect the remote controller cable to the terminal block on the bottom case.

Peel off 6 mm of the remote controller cable sheath as shown in the figure below, and thread the cable from behind the bottom

case. Thread the cable to the front of the bottom case so that the peeled part of the cable cannot be seen behind the bottom

case. Connect the remote controller cable to the terminal block on the bottom case.

(1) Installation work

Controller can be installed either in the switch box or directly on the wall. Perform

the installation properly according to the method.

1

Drill a hole in the wall.

■

Installation using a switch box

Drill a hole in the wall, and install the switch box on the wall.

Connect the switch box to the conduit tube.

■

Direct wall installation

Drill a hole in the wall, and thread the cable through it.

2

Seal the cable access hole with putty.

■

Installation using a switch box

Seal the remote controller cable access hole at the connection of switch

box and conduit tube with putty.

3

Prepare the bottom case of the remote controller.

■

Direct wall installation

Seal the hole through which the cable is threaded with putty.

To reduce the risk of electric shock, malfunctions, or fire, seal the

gap between the cables and cable access holes with putty.

Wall

Conduit

tube

Locknut

Switch box

Seal the gap

with putty.

Remote

controller cable

Bushing

Bottom case

Front cover and top case

10 (13/32)

6 (1/4)

unit: mm(in)

Sheath

Thread the sheath part

of the cable to the front.

Thread the cable.

Front

Back

2-core wire must not

be seen on the back.

Connect the cable.

(non-polarized)

Connect the cable

so that the cable

sheath is not

pinched.

To reduce the risk of electric shock, shorting, or malfunctions, keep

wire pieces and sheath shavings out of the terminal block.

Important

Do not use solderless terminals to connect cables to the terminal

block.

Solderless terminals may come in contact with the circuit board and

cause malfunctions or damage the controller cover.

Seal the gap with putty.

Route the cable behind

the remote controller.

Remote controller

cable

WT06695X01_1_GB_A5.fm Page 5 Tuesday, August 7, 2012 3:29 PM