12

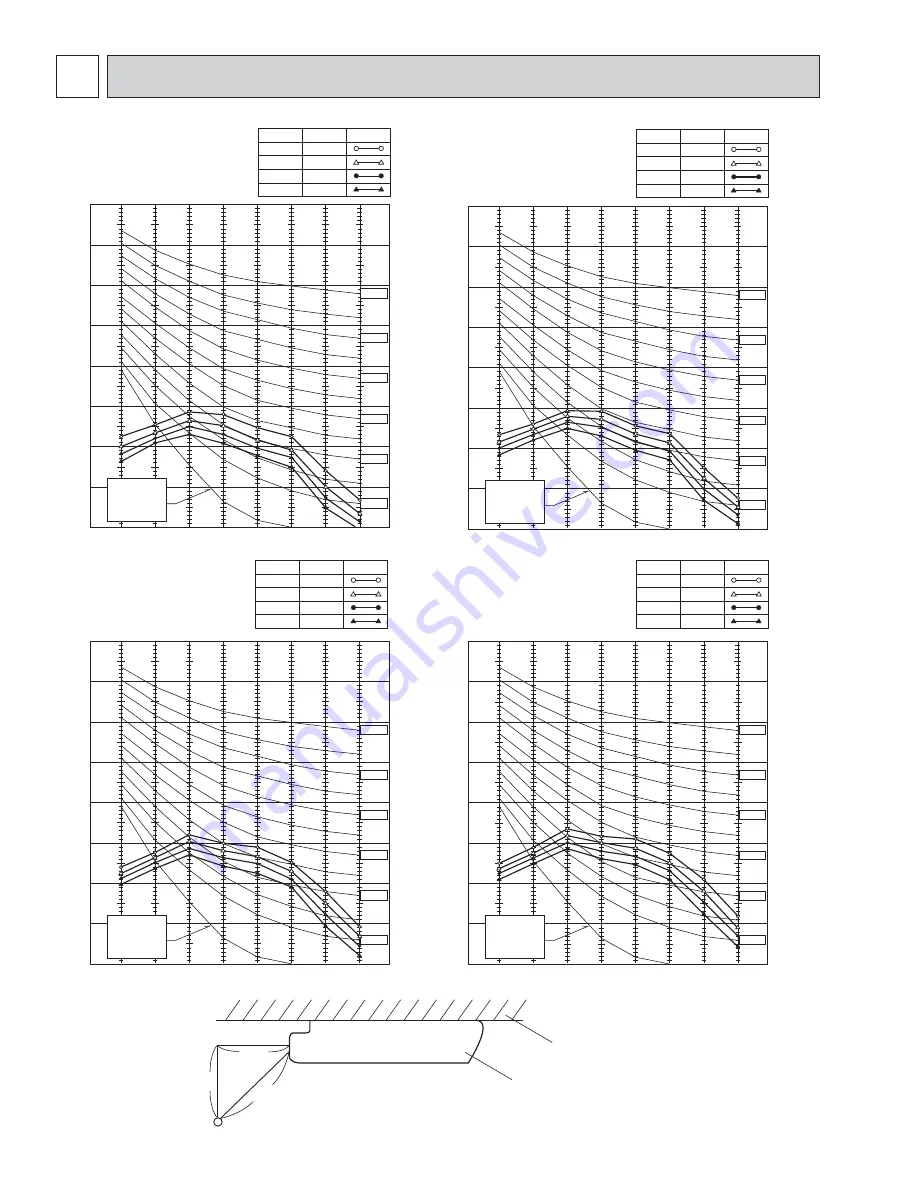

NOISE CRITERION CURVES

5

NOTCH

High

Medium1

Medium2

Low

SPL(dB)

40

37

35

33

LINE

90

80

70

60

50

40

30

20

10

63

125

250

500

1000

2000

4000

8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCT

A

VE BAND SOUND PRESSURE LEVEL, dB (0 dB

0.0002

bar)

BAND CENTER FREQUENCIES, Hz

90

80

70

60

50

40

30

20

10

63

125

250

500

1000

2000

4000

8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

BAND CENTER FREQUENCIES, Hz

OCT

A

VE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002

μ

bar)

NOTCH

High

Medium1

Medium2

Low

SPL(dB)

41

39

37

35

LINE

90

80

70

60

50

40

30

20

10

63

125

250

500

1000

2000

4000

8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

BAND CENTER FREQUENCIES, Hz

OCT

A

VE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002

μ

bar)

NOTCH

High

Medium1

Medium2

Low

SPL(dB)

43

41

39

37

LINE

90

80

70

60

50

40

30

20

10

63

125

250

500

1000

2000

4000

8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

BAND CENTER FREQUENCIES, Hz

OCT

A

VE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002

μ

bar)

NOTCH

High

Medium1

Medium2

Low

SPL(dB)

45

43

41

39

LINE

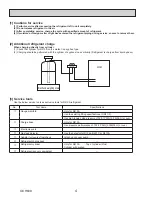

3.3 ft

3.3 ft

Main unit

about 4.62 ft

MICROPHONE

ceiling

PCA-A24KA7.TH

PCA-A30KA7.TH

PCA-A36KA7.TH

PCA-A42KA7.TH

OCH638