21

9-3. SELF-DIAGNOSIS ACTION TABLE

Note:

Errors to be detected in outdoor unit, such as codes starting with F, U or E (excluding E0 to E7),

are not covered in this document. Please refer to the outdoor unit service manual for the details.

Check code

Abnormal point and detection method

Cause

Countermeasure

P1

Room temperature thermistor (TH1)

1

The unit is in 3-minute resume

prevention mode if short/open of

thermistor is detected. Abnormal if the

unit does not reset normally after 3 min-

utes. (The unit returns to normal opera-

tion, if it has been reset normally.)

2

Constantly detected during cooling,

drying, and heating operation.

Short: 194°F [90

:

] or more

Open:

í

40°F [

í

40

:

] or less

1

Defective thermistor

characteristics

2

Contact failure of connector

(CN20) on the indoor controller

board (Insert failure)

3

Breaking of wire or contact

failure of thermistor wiring

4

Defective indoor controller board

1

–

3

Check resistance value of thermistor.

32°F [0

:

] ....15.0 k

"

50°F [10

:

] ......9.6 k

"

68°F [20

:

] ......6.3 k

"

86°F [30

:

] ......4.3 k

"

104°F [40

:

] ......3.0 k

"

If you put force on (draw or bend) the lead

wire with measuring resistance value of

thermistor, breaking of wire or contact fail-

ure can be detected.

2

Check contact failure of connector (CN20)

on the indoor controller board. Refer to

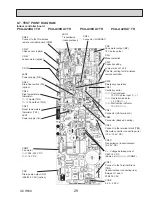

9-7. TEST POINT DIAGRAM

.

Turn the power on again and check

restart after inserting connector again.

4

Check room temperature display on remote con-

troller.

Replace indoor controller board if there is abnor-

mal difference with actual room temperature.

Turn the power off, and on again to operate

after check.

P2

Pipe temperature thermistor/liquid (TH2)

1

The unit is in 3-minute resume

prevention mode if short/open of

thermistor is detected. Abnormal if the

unit does not reset normally after 3 min-

utes. (The unit returns to normal opera-

tion, if it has been reset normally.)

2

Constantly detected during cooling,

drying, and heating (except defrosting)

operation

Short: 194°F [90

:

] or more

Open:

í

40°F [

í

40

:

] or less

Note:

When all of the following conditions are sat-

isfied, the error is not detected:

1) During cooling operation, or for 3 min-

utes after cooling operation is stopped.

2) Up to 16 minutes from 10 seconds after

cooling operation is started.

3) Outside temperature <

í

22°F [

í

30

:

]

1

Defective thermistor

characteristics

2

Contact failure of connector

(CN44) on the indoor controller

board (Insert failure)

3

Breaking of wire or contact

failure of thermistor wiring

4

Defective refrigerant circuit is

causing thermistor temperature

of 194°F [90

:

] or more, or

í

40°F [

í

40

:

] or less.

5

Defective indoor controller board

1

–

3

Check resistance value of thermistor.

For characteristics, refer to (P1) above.

2

Check contact failure of connector (CN44)

on the indoor controller board. Refer to

9-7. TEST POINT DIAGRAM

.

Turn the power on and check restart

after inserting connector again.

4

Check pipe <liquid> temperature with

remote controller in test run mode. If pipe

<liquid> temperature is extremely low (in

cooling mode) or high (in heating mode),

refrigerant circuit may have defective.

5

Check pipe <liquid> temperature with

remote controller in test run mode. If

there is extremely difference with actual

pipe <liquid> temperature, replace indoor

controller board.

Turn the power off, and on again to operate

after check.

P4

Contact failure of drain float switch

(CN4F)

Extract when the connector of drain float

switch is disconnected.

(

3

and

4

of connector CN4F is not

short-circuited.)

Constantly detected during operation

1

Contact failure of connector

(Insert

failure)

2

Defective indoor controller board

1

Check contact failure of float switch connector.

Turn the power on again and check after insert-

ing connector again.

2

Operate with connector (CN4F) short-

circuited.

Replace indoor controller board if abnor-

mality reappears.

P5

Drain over flow protection operation

1

Suspensive abnormality, if drain float

switch is detected to be underwater for 1

minute and 30 seconds continuously with

drain pump on.

Compressor and indoor fan will be turned

off.

2

Drain pump is abnormal if the condition

above is detected during suspensive

abnormality.

3

Constantly detected during drain pump

operation

1

Malfunction of drain pump

2

Defective drain

Clogged

drain

pump

Clogged

drain

pipe

3

Defective drain float switch

Catch of drain float switch or

malfunction of moving parts

cause drain float switch to be

detected under water (Switch

On)

4

Defective indoor-controller

board

1

Check if drain-up machine works.

2

Check drain function.

3

Remove drain float switch connector CN4F

and check if it is short (Switch On) with the

moving part of float switch UP, or OPEN with

the moving part of float switch down.

Replace float switch if it is short with the mov-

ing part of float switch down.

4

Replace indoor controller board if it is

short-circuited between

3

–

4

of the drain

float switch connector CN4F and abnor-

mality reappears.

It is not abnormal if there is no problem

about the above-mentioned

1

–

4

.

Turn the power off, and on again to operate

after check.

OCH638