22

Check code

Abnormal point and detection method

Cause

Countermeasure

P6

Freezing/overheating protection is work-

ing

1

Freezing protection (Cooling mode)

In case when

outside temperature >

í

4°F [

í

20

:

]

The unit is in 6-minute resume preven-

tion mode if pipe <liquid or condenser/

evaporator> temperature stays under

í

5°F [

í

15

:

] for 3 minutes, 3 minutes

after the compressor started.

Abnormal if it stays under

í

5°F [

í

15

:

]

for 3 minutes again within 16 minutes

after 6-minute resume prevention mode.

In case when

outside temperature

[

í

4°F [

í

20

:

]

The unit is in 6-minute resume preven-

tion mode if pipe <liquid or condenser/

evaporator> temperature stays under

í

31°F [

í

35

:

] for 3 minutes, 3 minutes

after the compressor started.

Abnormal if it stays under

í

31°F [

í

35

:

]

for 3 minutes again within 16 minutes

after 6-minute resume prevention mode.

2

Overheating protection (Heating mode)

The unit is in 6-minute resume

prevention mode if pipe <liquid or con-

denser/evaporator> temperature is

detected as over 158°F [70

:

] after the

compressor started. Abnormal if the tem-

perature of over 158°F [70

:

] is detected

again within 30 minutes after 6-minute

resume prevention mode.

(Cooling or drying mode)

1

Clogged filter (reduced airflow)

2

Short cycle of air path

3

Low-load (low temperature)

operation out of the tolerance

range

4

Defective indoor fan motor

Fan motor is defective.

Indoor controller board is defec-

tive.

5

Defective outdoor fan control

6

Overcharge of refrigerant

7

Defective refrigerant circuit

(clogs)

(Heating mode)

1

Clogged filter (reduced airflow)

2

Short cycle of air path

3

Over-load (high temperature)

operation out of the tolerance

range

4

Defective indoor fan motor

Fan motor is defective.

Indoor controller board is defec-

tive.

5

Defective outdoor fan control

6

Overcharge of refrigerant

7

Defective refrigerant circuit

(clogs)

8

Bypass circuit of outdoor unit is

defective.

(Cooling or drying mode)

1

Check clogs of the filter.

2

Remove shields.

4

Refer to

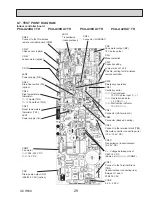

9-6. HOW TO CHECK THE

PARTS

.

5

Check outdoor fan motor.

67

Check operating condition of refriger-

ant

circuit.

(Heating mode)

1

Check clogs of the filter.

2

Remove shields.

4

Refer to

9-6. HOW TO CHECK THE

PARTS

.

5

Check outdoor fan motor.

6

–

8

Check operating condition of refriger-

ant circuit.

P8

Pipe temperature

<Cooling mode>

Detected as abnormal when the pipe tem-

perature is not in the cooling range 3 min-

utes after compressor start and 6 minutes

after the liquid or condenser/evaporator

pipe is out of cooling range.

Note 1: It takes at least 9 minutes to detect.

Note 2: Abnormality P8 is not detected in

drying mode.

Cooling range:

í

5.4°F [

í

3°C]

]

(TH

í

TH1)

TH: Lower temperature between liquid pipe

temperature (TH2) and condenser/

evaporator temperature (TH5)

TH1: Intake temperature

<Heating mode>

When 10 seconds have passed after the

compressor starts operation and the hot

adjustment mode has finished, the unit is

detected as abnormal when condenser/

evaporator pipe temperature is not in heat-

ing range within 20 minutes.

Note 3: It takes at least 27 minutes to

detect abnormality.

Note 4: It excludes the period of defrosting.

(Detection restarts when defrosting

mode is over.)

Heating range: 5.4°F [3°C]

[

(TH5

í

TH1)

1

Slight temperature difference

between indoor room

temperature and pipe <liquid

or

condenser/evaporator>

temperature

thermistor

Shortage of refrigerant

Disconnected holder of pipe

<liquid or condenser/

evaporator> thermistor

Defective refrigerant circuit

2

Converse connection of

extension pipe (on plural units

connection)

3

Converse wiring of indoor/

outdoor unit connecting wire (on

plural units connection)

4

Defective detection of indoor

room temperature and pipe

<condenser/evaporator>

temperature

thermistor

5

Stop valve is not opened

completely.

1

–

4

Check pipe <liquid or condenser/

evaporator> temperature with room

temperature display on remote con-

troller and outdoor controller circuit

board.

Pipe <liquid or condenser/evapora-

tor> temperature display is indicated

by setting SW2 of outdoor controller

circuit board as follows.

Conduct temperature check with outdoor

controller circuit board after connecting

µ

A-Control Service Tool(PAC-SK52ST)’.

23

Check converse connection of exten-

sion pipe or converse wiring of indoor/

outdoor unit connecting wire.

(

(

OCH638