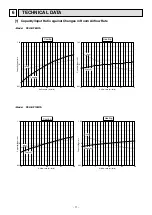

Exter

nal static pressure (P

a)

40

50

60

70

80

50

0

200

Operating airflow range

Airflow rate (m

3

/min)

100

150

220

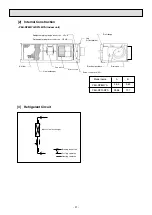

Exter

nal static pressure (P

a)

60

70

80

90

100

50

0

200

Operating airflow range

Airflow rate (m

3

/min)

100

150

220

PEH-RP8MYA

PEH-RP10MYA

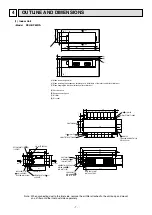

[4] Airflow Characteristic Curves

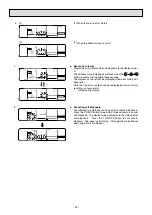

[5] Center of Gravity (Indoor unit)

Item

Model name

PEH-RP8MYA

PEH-RP10MYA

Center of gravity

X

630

730

Y

230

235

Z

240

240

unit : (mm)

X

Y

Z

Top of the unit

• Models PEH-RP8MYA/RP10MYA

- 17 -