3

6

6.3

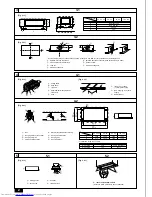

[Fig. 6.2.1]

[Fig. 6.3.1]

6.2

7

7.2

[Fig. 7.2.1]

[Fig. 7.2.2]

[Fig. 7.3.1]

[Fig. 8.1.1]

[Fig. 8.1.2]

38

350

70

476

20

20

630

60

60

C

550

606

70

178

192

338-353

8

290

3-18

45

135

52

B

D

A

E

A

Refrigerant pipe (liquid pipe): HP

B

Drain pipe

C

Hanging bolt pitch

D

Refrigerant pipe (gas pipe): LP

E

Filling port

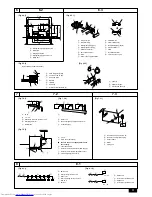

A

H

C

D

G

E

*1

F

B

J

I

M

N

L

K

O

A

“0-0 gas” mark

B

“INNER” mark

C

“OUTER” mark

D

Flare insulation (2)

E

Refrigerant piping (gas)

F

Refrigerant piping (liquid)

G

Field refrigerant piping

H

Pipe insulation (1)

I

Insulation material

J

Flare

K

Pull in this direction.

L

Insulation material

M

Flare

N

There must be no gap.

O

Move to the original position.

[Fig. 6.3.2]

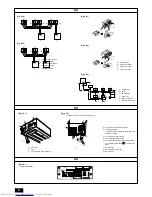

C

B

A

D

E

F

G

*2

20

20

20

20

C

B

A

*3

*4

A

Field refrigerant piping

B

There must be no gap.

C

Unit body plate

D

OUTER

E

INNER

F

Unit body

G

Provided flare insulation (2)

A

Tape (3)

B

Fasten with tape.

C

Provided tie band (4)

(figure showing the flare insulation)

D

I

C

H

G

K

I

J

3

C: 30 cm

G

Drain hose (Accessory)

s

s

s

s

s

Be sure to use the supplied drain hose

(Accessory).

H

Less than 300 mm

I

Hard vinyl chloride 90° elbow (field supply)

J

Hard vinyl chloride (VP-25) (field supply)

K

Tie band (small) (Accessory)

D

D

D

E

F

2

D

Indoor unit

E

Take as large as possible. About 10 cm

F

Collected pipes

A

C

B

A

B

1

A: 25 cm

B: 1.5 – 2 m

A

Downward pitch of more than 1/100

B

Insulating material

C

Metal brace

D

C

E

B

A

A

Insert the pump’s end 2 to 4 cm.

B

Remove the polyethylene plug.

C

About 1000 cc

D

Water

E

Filling port

E

F

C

20 ~ 80

G

H

C

100 · 125

E

Switch 16 A

F

Overcurrent protection 16 A

G

Switch 16 A

H

Overcurrent protection 16 A

A

B

D

E

C

C

C

C

C

C

C

A

Switch 16 A

B

Overcurrent protection 16 A

C

Indoor unit

D

Total operating current be less

than 16 A

E

Pull box

[Fig. 7.2.3]

7.3

8

8.1

[Fig. 6.3.3]