8. PRESS THE D KEY

THE MACHINE WILL LOAD THE F4 FLOPPY

WAIT UNTIL THE DISPLAY CHANGES TO:

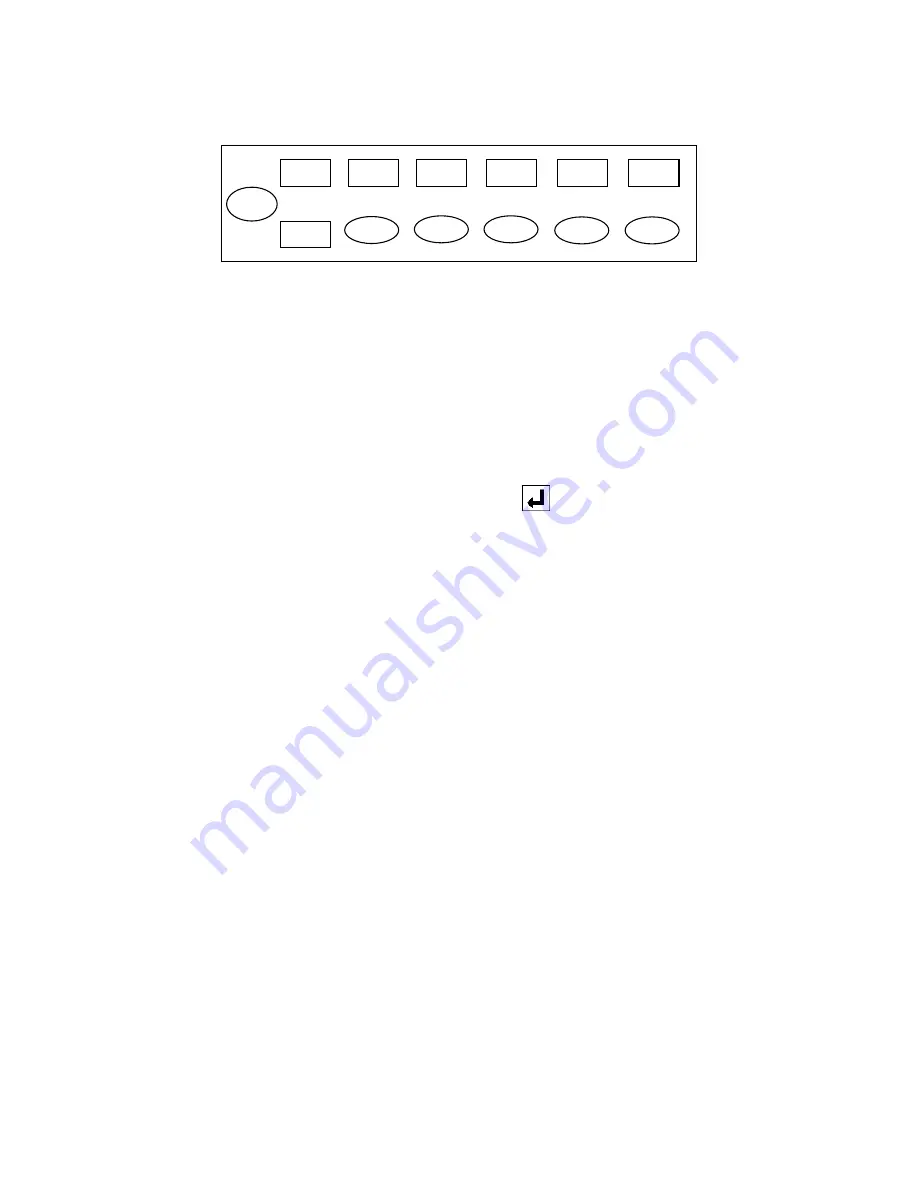

↑

M

-

3

1

0

LED1

LED2

LED3

LED4

LED5

↓

F

A

B

C

D

THE MACHINE WILL START BEEPING

SOFTWARE INSTALLATION IS COMPLETED

TURN OFF THE POWER

TAKE OUT THE F4 FLOPPY DISK AND STORE ALL THE SOFTWARE DISKS SO THEY WON’T GET LOST

YOU MAY NEED THEM AGAIN SOMEDAY

NOTE 1: WHEN YOU POWER THE MACHINE BACK UP, THE LCD DISPLAY WILL SHOW THAT THERE IS

NO PATTERN IN THE MACHINE. YOU MUST USE THE LCD DISPLAY TO READ A PATTERN STORED ON A

FLOPPY OR MAKE A PATTERN. PRESS THE ENTER KEY TO GO TO THE STANDARD DISPLAY

NOTE 2: HOWEVER, IF THE SOFTWARE HAS BEEN RE-INSTALLED AND IF THERE WERE PATTERNS

IN THE INTERNAL MEMORY OF THE MACHINE, THEY ARE STILL THERE. READ THEM USING THE

PATTERN READ FROM INTERNAL MEMORY PROCEDURE.

H