[16] - 7

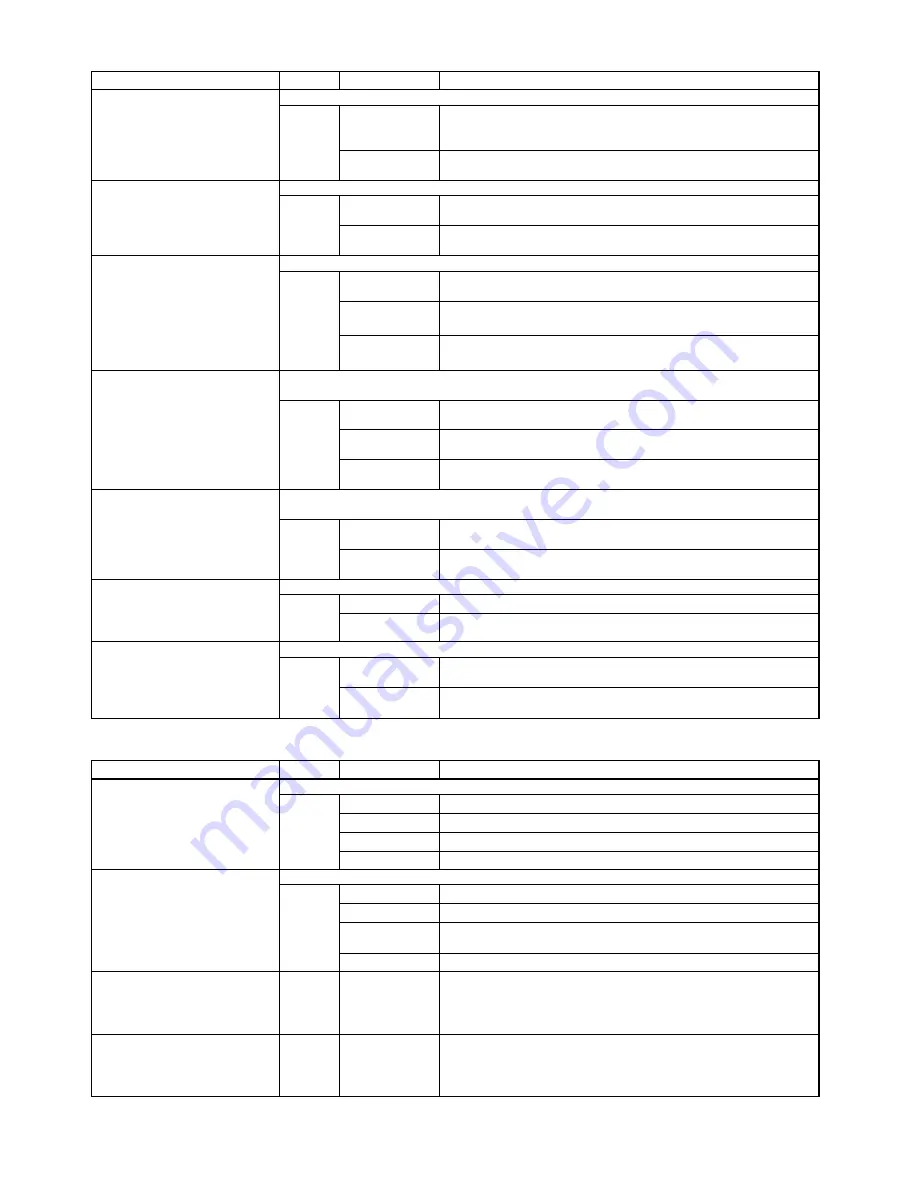

8.Halt

Function Unit

Setting

range

Specification

Stop position when halt switch is pressed while non stitch feed operation can be set

- CP

When the HALT switch is turned ON, non-stitching feed will be

executed until the breakpoint (the position where non-stitching

feed direction changes).

STF

Stop position setting when

halt switch is pressed while

non stitch feed operation

ST

When the HALT switch is turned ON, the machine will stop at that

position.

Sets needle positioning when the halt switch is turned on.

- DN

When the HALT switch is on, the needle will stop at the DOWN

position.

STN

Needle position when halt

switch is turned on.

UP

When the HALT switch is on, the needle will stop at the UP

position.

Selects the state of each output when the HALT switch is turned on.

- AL

All outputs will be held (ON is maintained). (exclude wiper,

trimmer, thread release)

FU

Keep the output state of the clamp relation.(keep output

excluding general purpose, wiper, trimmer and tension release)

STS

The state of each output

when the HALT switch is

turned on

OF

Release output for the clamp relation, general purpose, wiper,

trimmer, tension release.

The operation for when the HALT switch is pressed twice at the needle down position can be

selected.

- UT

When the HALT switch is turned on again, the needle will stop at

the up position after thread trimming.

UP

When the HALT switch is turned on again, the needle will stop at

the up position without thread trimming. (when set (STN.)=[DN])

ST2

HALT switch two-press

operation (stop at down

position)

ST

The needle will stay at the down position even if the HALT switch

is turned ON again.

Sets the operation after HALT switch is turned on.

Please turn off the power after the setting change and restart again.

- --

Restarting is possible after the sewing machine is stopped by the

foot switch.

STP

Operation of power supply

after HALT switch is turned

on and off. <TURN OFF

THE POWER>

PD

Same behavior as emergency stop switch. please turn off the

power and restart again.

Sets the clamp condition during halt state by the STOP code

- FU

Clamp goes up after machine is stop

STD

Clamp condition during

halt state by the STOP

code

FD

Keeps clamp condition after machine is stop

After needle down position stop, restart operation can be selected.

- OF

After needle down position stop, machine restarts from the stop

position ( needle goes down at the same position twice)

STL

Prevention of two drops at

the same point after HALT

ON

After needle down position stop, machine restarts from next stitch

point ( needle does not go down at the stop position)

9.Counter

Function Unit

Setting

range

Specification

Sets function of UP counter

- --

Up counter is not executed

ED

Up counter decreases every 1 sewing pattern is executed

ST

Up counter decreases every N stitches (N is set by [CND] setting)

CUP

Sets function of UP

counter

CY

Do not use

Sets function of DOWN counter

- --

Down counter is not executed

ED

Down counter increases every 1 sewing pattern is executed

ST

Down counter increases every N stitches (N is set by [CNU]

setting)

CDN

Sets function of DOWN

counter

CY

Do not use

CNU

Setting number of stitches

of each 1 count for UP

counter

stitches

5 ~ 1000

Setting of the number of stitches when "ST" of the CUP setting is

selected

CND

Setting number of stitches

of each 1 count for DOWN

counter

stitches

5 ~ 1000

Setting of the number of stitches when "ST" of the CDN setting

is selected

Summary of Contents for PLK-G-PAL

Page 1: ...INDUSTRIAL SEWING MACHINE MODEL PLK G PAL TECHNICAL MANUAL Operation Panel A180E606P12 ...

Page 2: ......

Page 199: ...MEMO ...

Page 200: ......