–38–

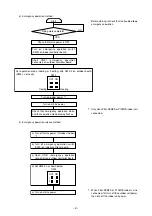

2) Judgment method and probable trouble mode

3) Electronic expansion valve motor replacement instructions

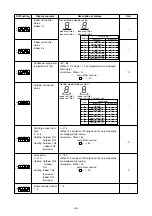

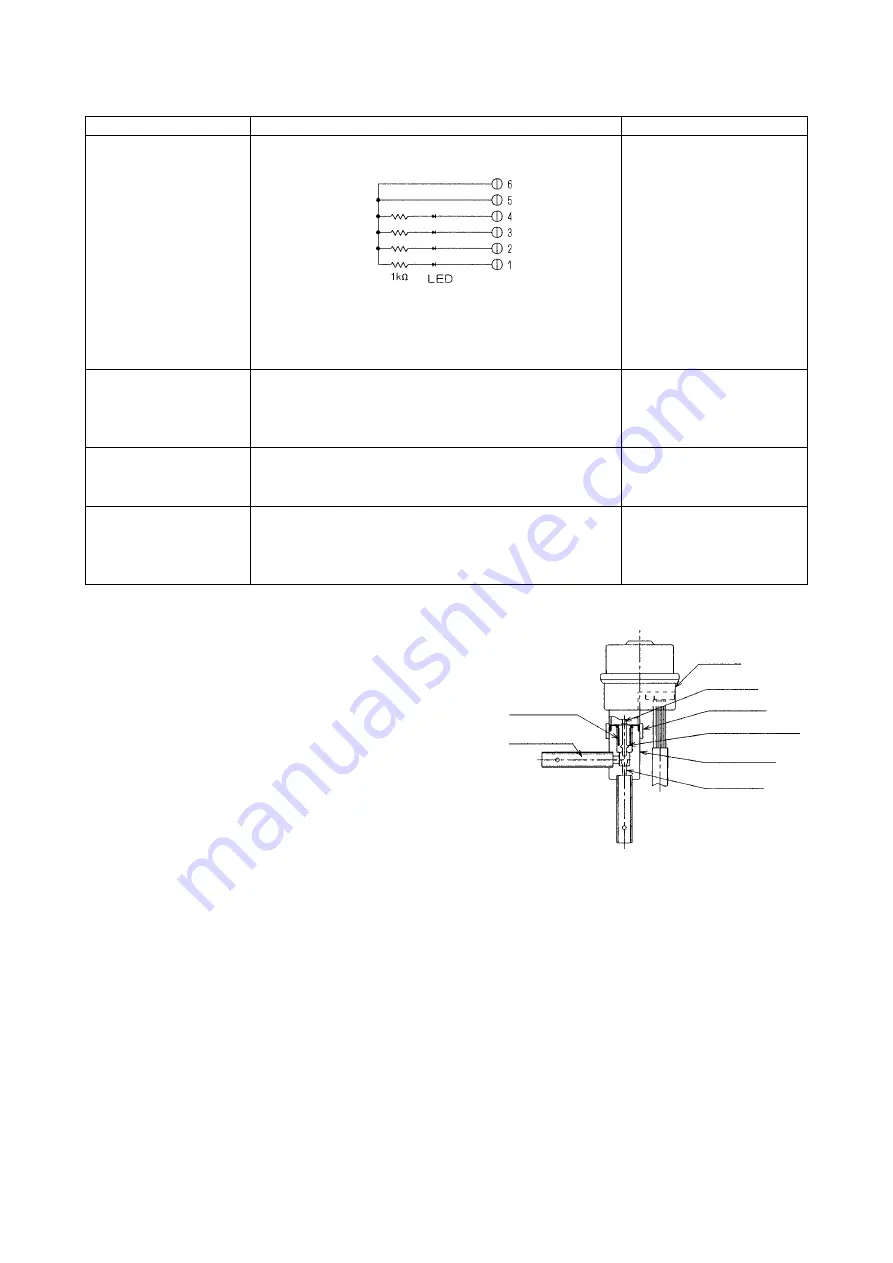

1. Description of construction

1.1 A lock nut connects the motor to the valve body.

1.2 The motor consists of a motor rotating section, rotation

transmission gear section, and a driver which converts

rotation to linear motion.

1.3 The valve body consists of a valve assembly, which

moves up and down, and an orifice.

A bellows at the top of the valve body block isolates the

refrigerant circuit from the atmosphere side.

Therefore, the motor is not exposed to the refrigerant.

2. Principle of operation

2.1 Pulses output from the control circuit board are sequentially supplied to four coils and the motor is rotated.

The motor can be rotated in either clockwise or counterclockwise by changing the order in which the pulses are

supplied.

2.2 The gear section reduces the motor speed to 1/30 and supplies the motor rotation to the motor output shaft.

2.3 The motor output shaft is threaded and is used as a driver.

2.4 The up and down motion of the end of the driver moves the valve assembly of the valve body up and down and

controls the flow by changing the distance between the orifice and the bottom end of the valve.

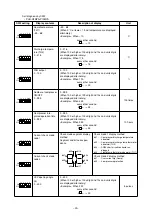

Trouble mode

Microcomputer drive cir-

cuit faulty

LEV mechanism locked

LEV motor coil open or

shorted

Connector connection in-

correct, or contact faulty

Judgment method

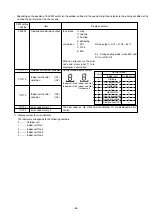

(1) Disconnect the control circuit board connector, and con-

nect the check LED shown below.

When the mains power is turned on, a pulse signal is out-

put for 10 seconds.

If the LED remains OFF or ON, the drive circuit is abnor-

mal.

(1) When the LEV is in the locked state and driven, the mo-

tor races. At this time, a soft clicking sound is generated.

When this sound is generated both when closing and

when opening, the mechanism is abnormal.

Measure the resistance between the coils (red-white, red-

orange, brown-yellow, brown-blue) with a multimeter.

If 150

Ω ±

10 %, the coil is normal.

(1) Visually check for loose connector terminals and check

the color of the lead wires.

(2) Disconnect the control circuit board connector and

check the continuity with a multimeter.

Remedy

When drive circuit is faulty, re-

place control circuit board.

Replace LEV

Replace LEV coil

Check continuity of faulty point

Valve assembly

Motor

Driver

Lock nut

Refrigerant

circuit

Valve body

Orifice

Bellows