–43–

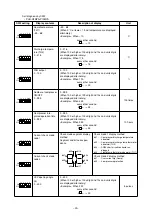

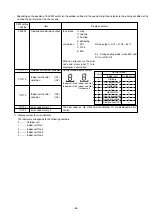

<Abnormality detected during unit operation: Outdoor unit>

Abnormal-

ity display

U2

U3

U4

U6

UE

Meaning of abnormality display and

abnormality troubleshooting

Discharge temperature abnormal

When the discharge thermistor tem-

perature (TH2) exceeds 118

°

C while

the compressor is operating, an ab-

normality is recognized.

49C trip (CN23 connector discon-

nected)

When connector CN23 opens while

the compressor is operating, an ab-

normality is recognized.

Discharge temp thermistor (TH2)

open or shorted.

When an open (0

°

C or lower) or

short (216

°

C or higher) is detected

while the compressor is operating, an

abnormality is recognized.

(Detection is disabled for 5 minutes

at compressor starting.)

Liquid temp thermistor (TH1) or

condenser/evaporater temp ther-

mistor (TH3) open or shorted.

When an open (–39

°

C or lower) or

short (88

°

C or higher) is detected

while the compressor is operating, an

abnormality is recognized. (Detection

is disabled for 7 minutes beginning

from 10 seconds after the compres-

sor starts and for 10 minutes after

return from defrosting.)

Compressor overcurrent trip

When the current value reaches the

overload set value or higher while the

compressor is operating, an abnor-

mality is recognized.

P8MYA .................................. 22 A

P10MYA ................................ 27 A

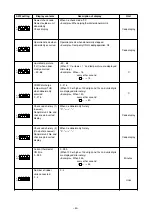

High pressure abnormal (63H1

trip)

Detected (3.3

+0

-0.15

MPa) by 63H1 trip

while compressor is operating.

63H1: Pressure switch (high pres-

sure)

OFF: 3.3 MPa

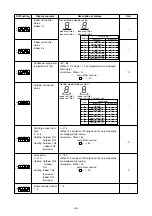

Cause

(1) Compressor overheating due to insuf-

ficient refrigerant.

(2) Thermistor faulty. (TH2)

(3) Outdoor controller board faulty.

(1) Shorting connector CN23 on outdoor

controller board dislodged or contact

faulty.

(1) Connector (CN3) dislodged or con-

nect faulty.

(2) Thermistor faulty.

(3) Outdoor controller board faulty.

(1) Connector (TH1: CN2, TH3: CN4) dis-

lodged or contact faulty.

(2) Thermistor faulty.

(3) Outdoor controller board faulty.

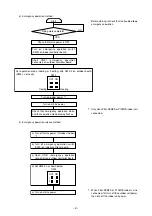

(1) Overload operation exceeding unit us-

age range limit.

(2) Power supply terminal voltage low.

(3) Power supply missing phase.

(4) Compressor motor faulty.

(5) Compressor locked.

(6) Connector (CN22) on outdoor control-

ler board dislodged or contact faulty.

(7) 51C disconnected or contact faulty.

(1) Started with ball valve closed.

(2) Connector (CN21) on outdoor control-

ler board dislodged or contact faulty.

(3) 63H1 disconnected or contact faulty.

(4) Indoor filter clogged. Power reset de-

tected during heating overload opera-

tion (Heating).

(5) Low indoor unit air flow (heating).

(6) Low outdoor unit air flow (cooling).

(7) Part faulty.

Judgment method and remedy

(1) Check input super heat.

Check for refrigerant leakage and

check piping length.

Charge with additional refrigerant.

(2)(3)

Turn off power and restart operation

and check if U3 is displayed within 8

minutes.

When U3 is displayed, carry out U3 pro-

cessing.

(Do not replace board at U2 display

only.)

(1) Repair shorting connector.

(1) Check connector contact and ther-

mistor wire.

(2) Check thermistor resistance value, or

check temperature by microcomputer.

(Check using SW2 self-diagnosis func-

tion.)

See page 36.

(3) Replace outdoor controller board.

(Replace board after sufficiently check-

ing 1 and 2.)

(1) Check connector contact and ther-

mistor wire.

(2) Check thermistor resistance value or

check temperature by microcomputer.

(Check using SW2 self-diagnosis func-

tion.)

See to page 36.

(3) Replace outdoor controller board.

(Replace board after sufficiently check-

ing 1 and 2)

(1) Check usage conditions.

(Check for short cycle operation.)

(2) Check power supply voltage.

(3) Check wiring for breaks and faulty con-

tact.

(4) Check motor winding resistance (See

page 35.)

(5) Replace compressor.

(6)(7)

After checking connections, restart and

check operation.

(1) Check if ball valve is fully open.

(2)(3)

Repair connector.

(4) Check indoor filter.

(5) Check flow duct static pressure and for

faulty fan motor.

(6) Check for faulty outdoor fan motor.

(7) Replace pressure switch.