–47–

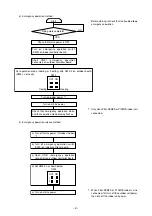

<Abnormality detected during unit operation: Indoor unit>

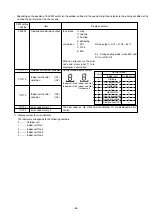

Abnormal-

ity display

P8

E4

Meaning of abnormality display and

abnormality troubleshooting

Piping temperature abnormal

<Cool>

When the piping temperature stays

outside the cooling area for 1 minute

after 3 minutes have elapsed since

the compressor was started, the in-

door fan operates at low speed. If the

piping temperature does not return

to the cooling area after 5 minutes

operation at low speed, an abnormal-

ity is recognized.

Note 1) It takes a minimum of 9 min-

utes for an abnormality to be

detected.

Note 2) At dry operation, P8 abnor-

mality is not detected.

<Heat>

When the piping temperature falls

outside the heating area and enters

the ventilation area after compressor

operation and the end of hot adjust,

the indoor fan stops and the piping

temperature does not return to the

heating area within 20 minutes after

10 seconds have elapsed after it left

the heating area, an abnormality is

recognized.

Note 3) It takes a minimum of 22

minutes and a maximum of

27 minutes for an abnormal-

ity to be detected.

Note 4) Except during defrosting

(Detected again after de-

frosting return.)

Remote control communication re-

ceive abnormal

1) When the indoor controller board

can not receive data normally

from the remote controller or an-

other indoor controller board even

once in 3 minutes, an abnormal-

ity is recognized.

2) When the indoor controller board

can not receive signals even once

in 2 minutes, an abnormality is

recognized.

Cause

(1) Indoor intake piping thermistor tem-

perature differential small.

- EInsufficient refrigerant

- EPiping thermistor holder dislodged.

- ERefrigerant circuit faulty.

(2) Extension piping (When multiple units

connected).

(3) Indoor/outdoor connection wire

(When multiple units connected).

(4) Indoor intake piping thermistor detec-

tion faulty.

(1) Remote controller transmission line

contact faulty.

(2) All remote controllers set as “slave”

remote controller.

(3) Remote controller send/receive circuit

faulty.

(4) Indoor controller board send/receive

circuit faulty.

(5) Noise entered on remote controller

transmission line.

Judgment method and remedy

(1) Operate in test run mode and check

piping temperature.

(2)(3)

Check extension piping or indoor/out-

door connection wire.

(4) Check remote controller room tempera-

ture display and piping temperature in

test run mode.

(1) Check if indoor unit or remote control-

ler transmission line disconnected or

loose.

(2) Set one remote controller as “master”.

When there are no problems at the

above

(3) Perform remote controller diagnosis.

a) [RC OK] display

Remote controller normal.

Check by turning power off and on.

If the abnormality occurs again, replace

indoor controller board.

b) [RC NG] display

Replace remote controller.

c) [RC E3] display

[ERC00-66] noise, etc. is probable

cause.