25

Transmission data from remote controller

Transmission data on transmission path

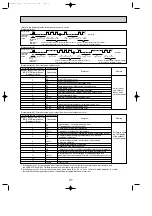

When the number of data errors is "02":

D

Press the

ON/OFF

button twice within 3 seconds. The self-diagnosis

address or refrigerant address will flash.

When the error history is reset, the display will look like the one shown below.

However, if you fail to reset the error history, the error content will be displayed again.

5

Cancel self-diagnosis.

Self-diagnosis can be cancelled by the following 2 methods.

H

Press the

CHECK

button twice within 3 seconds.

➔

Self-diagnosis will be cancelled and the screen will return to the previous state in effect before the start

of self-diagnosis.

5

Press the

ON/OFF

button.

➔

Self-diagnosis will be cancelled and the indoor unit will stop.

12-3-3. Remote Controller Diagnosis

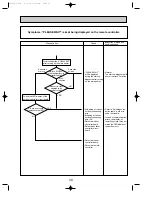

If the air conditioner cannot be operated from the remote controller, diagnose the remote controller as explained below.

1

First, check that the power-on indicator is lit.

If the correct voltage (DC12 V) is not supplied to the remote controller, the

indicator will not light.

If this occurs, check the remote controller's wiring and the indoor unit.

2

Switch to the remote controller self-diagnosis mode.

H

Press the

CHECK

button for 5 seconds or more. The display content will

change as shown below.

A

Press the

FILTER

button to start self-diagnosis.

3

Remote controller self-diagnosis result

[When the remote controller is functioning correctly]

Check for other possible causes, as there is no problem with the remote

controller.

[When the remote controller malfunctions]

(Error display 1)

"NG" blinks.

➝

The remote controller's transmitting-receiv-

ing circuit is defective.

The remote controller must be replaced with a new one.

[Where the remote controller is not defective, but cannot be operated.]

(Error display 2)

[E3], [6833] or [6832] flashes.

➝

Transmission is not possible.

There might be noise or interference on the transmission path, or the indoor unit

or other remote controllers are defective. Check the transmission path and other

controllers.

(Error display 3)

"ERC" and the number of data errors are displayed.

➝

Data error has occurred.

The number of data errors is the difference between the number of bits sent from

the remote controller and the number actually transmitted through the transmis-

sion path. If such a problem is occurring, the transmitted data is affected by noise,

etc. Check the transmission path.

4

To cancel remote controller diagnosis

H

Press the

CHECK

button for 5 seconds or more. Remote controller diagnosis will be cancelled, "PLEASE WAIT" and operation lamp will blink. After

approximately 30 seconds, the state in effect before the diagnosis will be restored.

Power on indicator

OC338C-1.qxp 07.5.24 11:31 AM Page 25