2-9

Installation

2Unpacking to Installation

2.2.2 Transportation procedures

(1) RH-3FRH/6FRH series

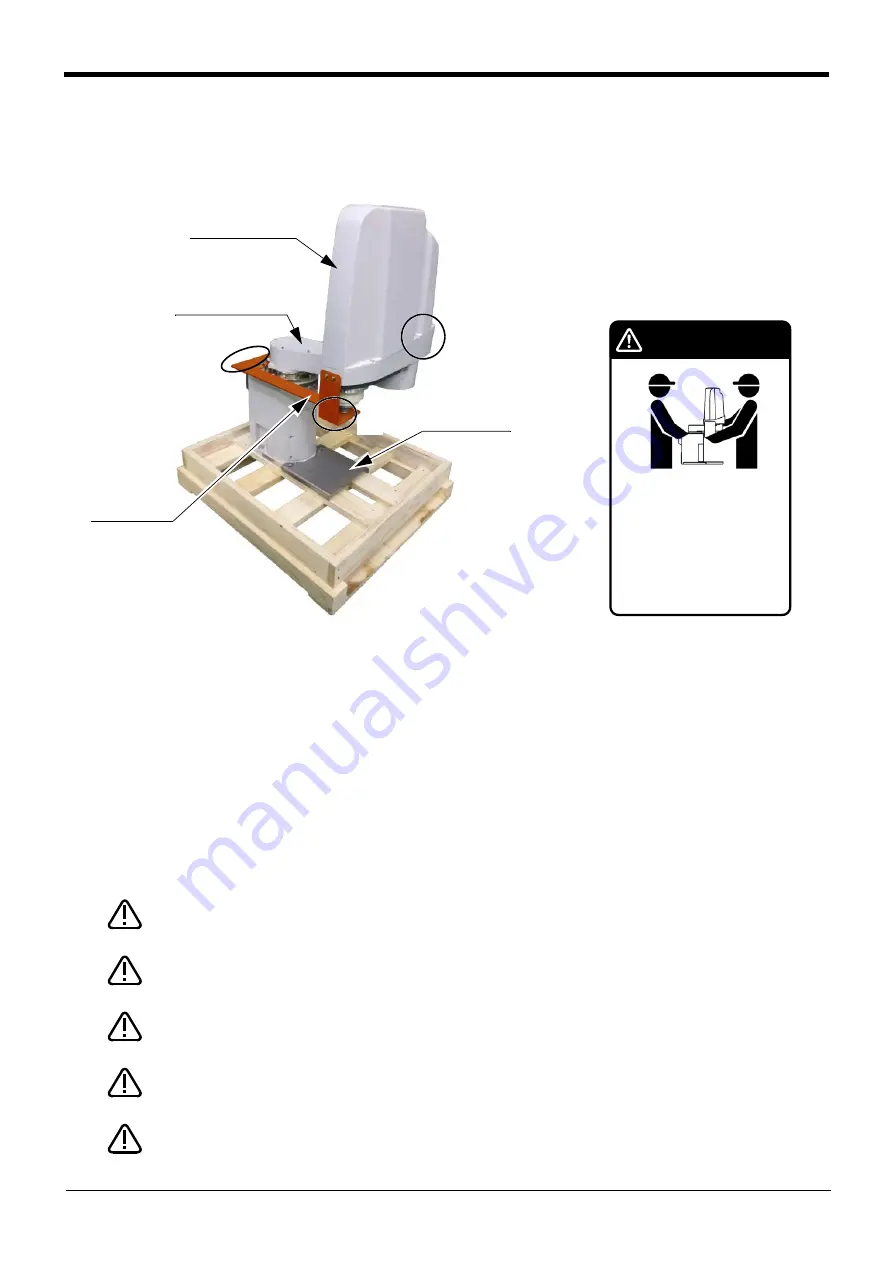

Fig.2-3 : Transportation of robot arm (RH-3FRH/6FRH series)

1) The robot must be transported by two workers with putting the fixing plate A and B. Place the robot on a

cart, etc., and move it to near the installation place. Transporting the robot with the following should be lim

-

ited to placing the robot on the frame or cart, and to positioning.

2) When transporting the robot arm, one person should hold the fixing plate A of No.2 arm <1> and No.2 arm

<2> and another person should hold the fixing plate A of base <3>. When transporting the robot, do not apply

force to the cover, or apply a strong shock on the robot.

3) Remove the fixtures after installing the robot.

4) Always attach the fixing plate, and follow the above procedures and methods to transport the robot for

secondary transportation, such as when changing the installation position.

If the arm is directly holded without using the specified fixing plate, or if it is holded in the work posture, the

configuration devices could be damaged, and the transportation workers will be subject to risk due to an

inadequate center of gravity position.

To prevent accidents, do not hold the robot from the left/right sides, or hold covers that

have no grips.

Be careful not to apply force to the shaft section (J3 axis). The shaft may be damaged

and the overload error may occur at the time of movement.

When installing the fixing tool again, place the robot in the posture where each axis

shows the values listed in

.

The robot should keep vertical. (not be horizontal)

It becomes the cause of the grease leakage or the trouble.

The ventilation duct is attached to the clean specification robot’s base section rear.

Please handle with care when transporting or installing the robot arm.

注意 CAUTION

VORSICHT

ロ ボ ッ ト の 運 搬 は 、 図 の 姿 勢 の よ う に

2 人 で お こ な っ て く だ さ い 。

T h e r o b o t m u s t a l w a y s b e

t r a n s p o r t e d b y t w o w o r k e r s .

B e i e i n e m T r a n s p o r t s o l l t e

d e r R o b o t e r v o n 2

P e r s o n e n a n d e n i n d e r

A b b i l d u n g g e z e i g t e n S t e l l e n

a n g e h o b e n w e r d e n .

Fixing plate B

No.1 arm

No.2 arm

<1>

<3>

Mass

RH-3FRH35** series: Approx. 31kg

RH-3FRH45** series: Approx. 32kg

RH-3FRH55** series: Approx. 33kg

RH-6FRH35** series: Approx. 39kg

RH-6FRH45** series: Approx. 40kg

RH-6FRH55** series: Approx. 41kg

Fixing plate A

<2>

*The grease for preventing rust is applied

at the tip of the shaft (J3 axis) in gen

-

eral-purpose environment robot.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION