Maintenance and inspection procedures 5-134

(2) RH-3FRHR series

■ Lubrication position and specifications

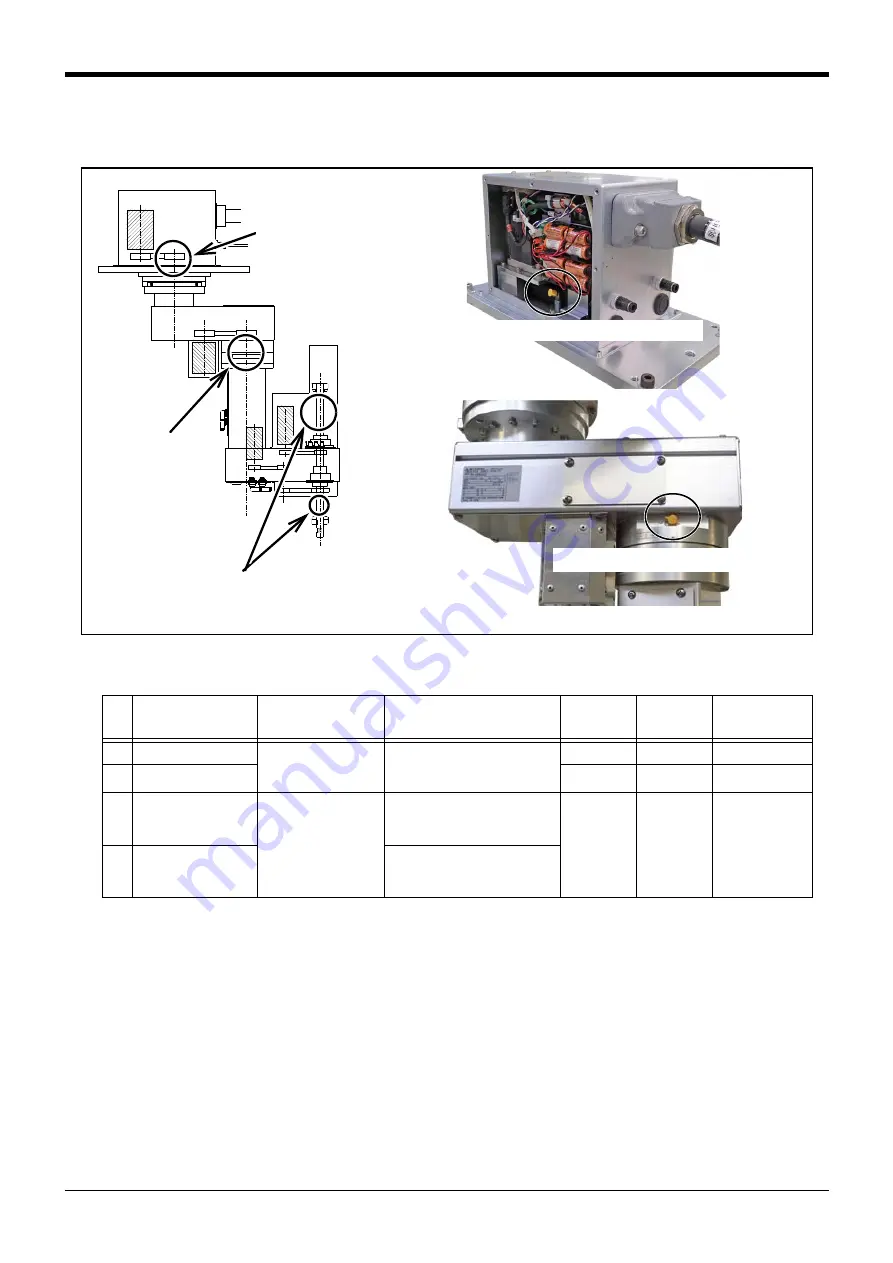

Fig.5-24 : Lubrication positions (RH-3FRHR series)

Table 5-11 : Lubrication specifications

[Caution]

・ The brand name of the grease shown in the

is the grease put in at shipping.

・ The lubrication interval is a cumulative value of the operation at the maximum speed. If the operation has been

suspended, or if the designated speed is slow, the lubrication time can be lengthened in proportion.

・Depending on the robot operation state, the lubrication interval will fluctuate, so determine the time according to

the state so that the grease does not run out.

・ By the maintenance forecast function of RT ToolBox3 (option) computes the guide of the lubrication hours put

together with the customer's operation status.

・ The numbers in the

correspond to the supply positions in

.

・ Because excessive lubrication leads to the grease leak, avoid it. And the number of times of lubrication limits to

3 times. The maintenance after it needs the overhaul work which replaces internal grease. Contact the dealer.

No.

Parts to be lubricated

Oiling method

Lubrication oil

Default charge amount (maker)

Lubrication

interval

Lubrication

amount guide

Cover to remove

<1> J1 axis reduction gears

Grease nipple

WC-610(Only addition)

Grease

Harmonic grease SK-1A

(Harmonic Drive Systems Inc.)

6,000 Hr

4.1 g

Base cover B (L)

<2> J2 axis reduction gears

6,000 Hr

1.8 g

-

<3>

Shaft

(General environment/

Clean specification)

Wipe the old grease, and

apply new grease

Marutenpu PS No.2

(KYODO YUSHI CO.,LTD. )

Every

2000km

movement

1 g

Motor cover J3

<4>

Shaft

(Waterproof specifica

-

tion)

NOK Klubersynth UH1 14-222

(NOK CORPORATION)

<1> J1 axis lubrication port

<2> J2 axis lubrica

-

tion port

<3> Shaft lubrication

<1> J1 axis lubrication port

Note)

<2> J2 axis lubrication port

Note)

Note) With the grease nipple cover (yellow)