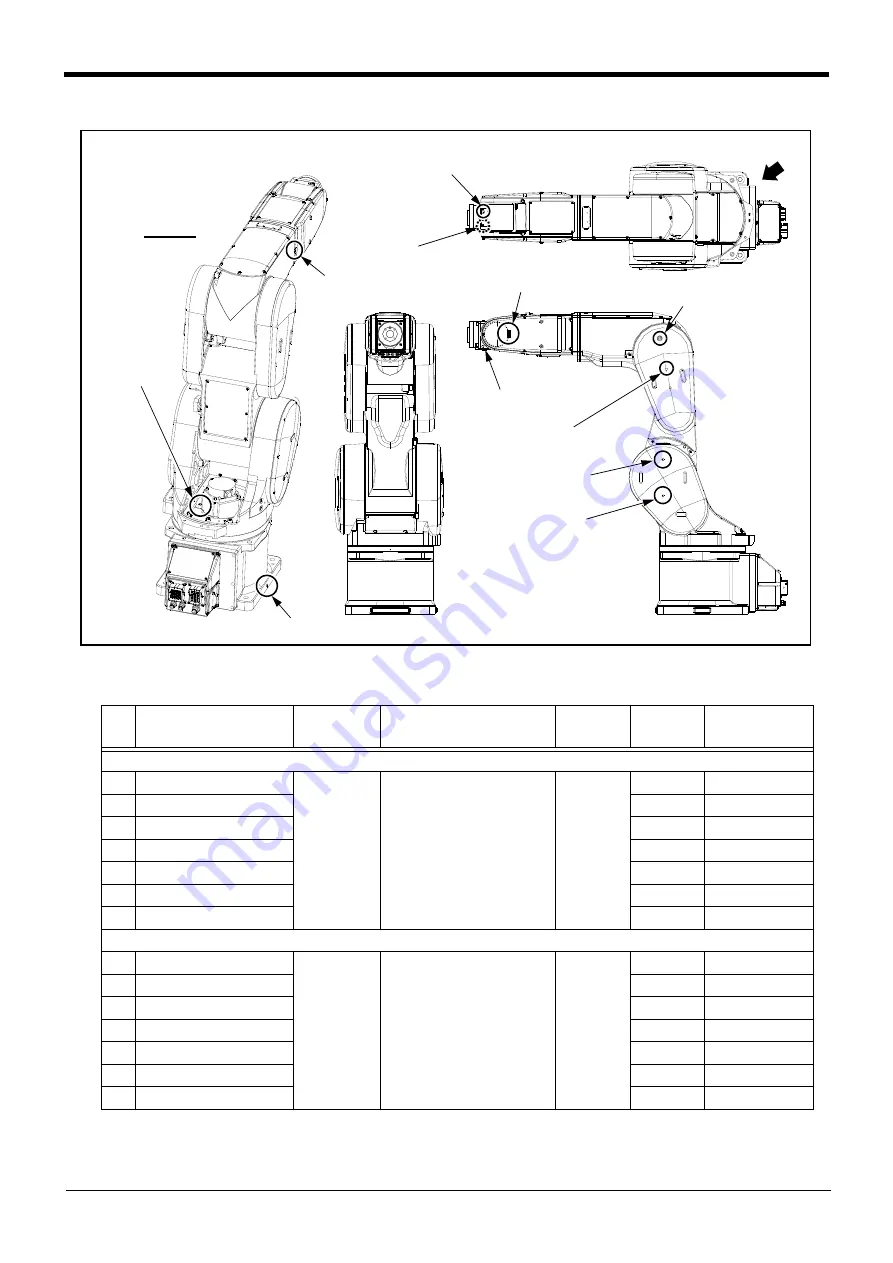

Maintenance and inspection procedures

Fig.5-16 : Lubrication positions (RV-13F series)

Table 5-4 : Lubrication specifications

No.

Parts to be lubricated

Note1)

Oiling method

Lubrication oil

(maker)

Lubrication

interval

Lubrication

amount

Cover to remove

RV-4F series

1

J1 axis reduction gears

Grease nipple

WA-610

4B No.2

(Harmonic Drive Systems Inc.)

24,000Hr

8g

J1 motor cover

2

J2 axis reduction gears

8g

3

J3 axis reduction gears

4g

No.1 arm cover L

4

J4 axis reduction gears

4g

5

J5 axis reduction gears

2g

6

J6 axis reduction gears

2g

7

J6 axis gears

1.3g

Wrist cover

RV-7F series

1

J1 axis reduction gears

Grease nipple

WA-610

4B No.2

(Harmonic Drive Systems Inc.)

24,000Hr

12g

J1 motor cover

2

J2 axis reduction gears

12g

3

J3 axis reduction gears

8g

No.1 arm cover L

4

J4 axis reduction gears

4g

5

J5 axis reduction gears

2g

6

J6 axis reduction gears

2g

7

J6 axis gears

1.3g

Wrist cover

3. J2 axis waste oil screw

A

5. J3 axis waste oil screw

1. J2 axis waste oil screw

View A

9. J6 axis lubrication port

(Reduction gears)

10. J6 axis lubrication port (Gear)

2. J1 axis

lubrication

port

(Reduction

gears)

7. J4 axis lubrication port

8. J5 axis lubrication port

RV-13F series

4. J2 axis reduction gears

6. J3 axis lubrication port

(Reduction gears)

8. J5 axis lubrication port (Back side)