OUTDOOR UNIT

B-114

INST

ALLA

TION

PROCEDURE

S series

OUTDOOR

UNIT

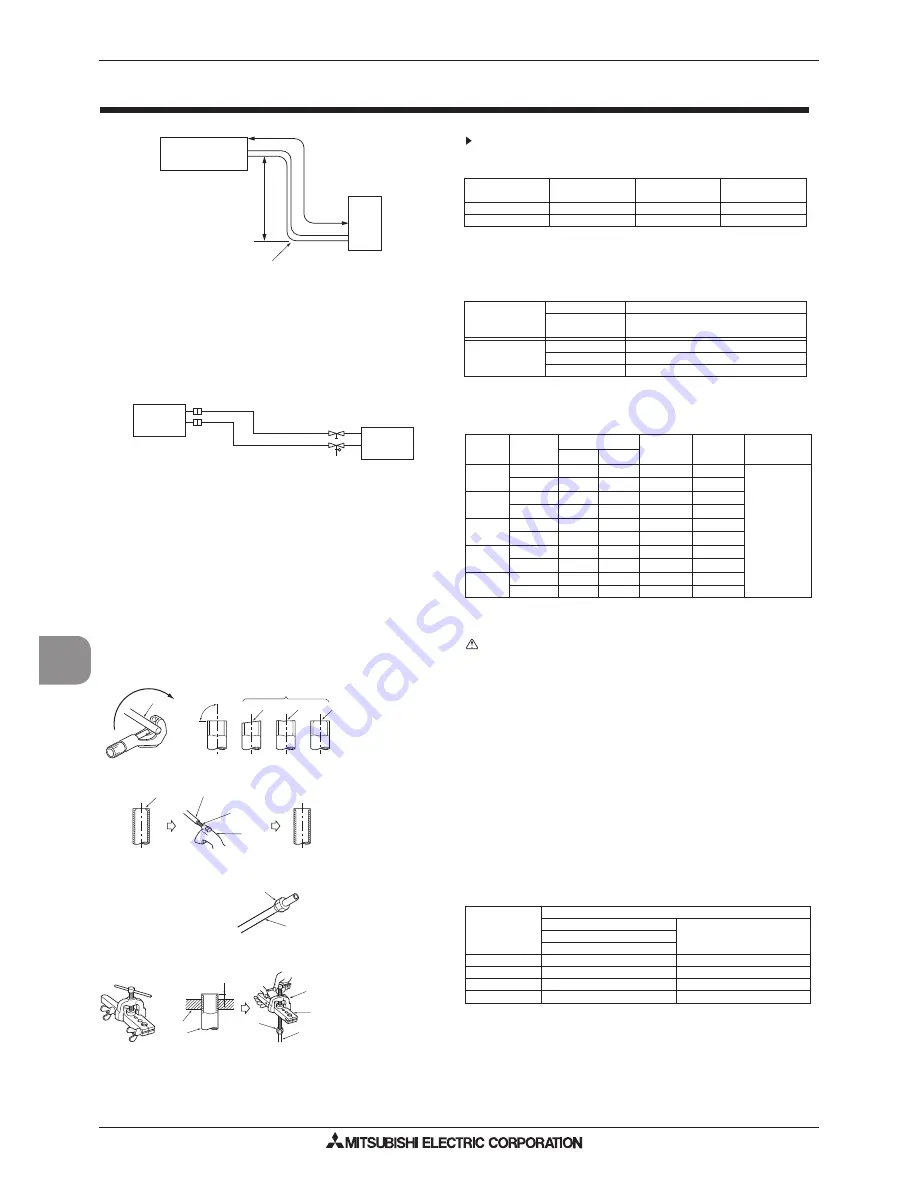

5.2. Flaring work

• Main cause of gas leakage is defect in flaring work.

Carry out correct flaring work in the following procedure.

5.2.1. Pipe cutting (Fig. 5-3)

• Using a pipe cutter cut the copper tube correctly.

5.2.2. Burrs removal (Fig. 5-4)

• Completely remove all burrs from the cut cross section of pipe/tube.

• Put the end of the copper tube/pipe to downward direction as you remove burrs in

order to avoid burrs drop in the tubing.

5.2.3. Putting nut on (Fig. 5-5)

• Remove flare nuts attached to indoor and outdoor unit, then put them on pipe/tube

having completed burr removal.

(not possible to put them on after flaring work)

5.2.4. Flaring work (Fig. 5-6)

• Carry out flaring work using flaring tool as shown at the right.

Dimension

Pipe diameter

A (mm)

(mm)

When the tool for R410A is used

B (mm)

Clutch type

6.35

0 - 0.5

9.1

9.52

0 - 0.5

13.2

12.7

0 - 0.5

16.6

15.88

0 - 0.5

19.7

Firmly hold copper tube in a die in the dimension shown in the table at above.

Copper tubes

Good

No good

Tilted

Uneven

Burred

Fig. 5-3

Burr

Copper tube/pipe

Spare reamer

Pipe cutter

Fig. 5-5

Fig. 5-6

Flare nut

Copper tube

Flaring tool

Die

Copper tube

Flare nut

Yoke

5. Refrigerant piping work

5.1. Refrigerant pipe (Fig. 5-1)

Check that the difference between the heights of the indoor and outdoor

units, the length of refrigerant pipe, and the number of bends in the pipe are

within the limits shown below.

Models

(A) Pipe length

(B) Height

(C) Number of

(one way)

difference

bends (one way)

SUZ-KA25/KA35

max. 20 m

max. 12 m

max. of 10

SUZ-KA50/KA60/KA71

max. 30 m

max. 30 m

max. of 10

• Height difference limitations are binding regardless of which unit, indoor or outdoor,

is positioned higher.

• Refrigerant adjustment ... If pipe length exceeds 7 m, additional refrigerant (R410A)

charge is required.

(The outdoor unit is charged with refrigerant for pipe length up to 7 m.)

Up to 7 m

No additional charge is required.

Pipe length

Exceeding 7 m

Additional charge is required.

(Refer to the table below.)

SUZ-KA25/KA35 type 30 g

%

(refrigerant piping length (m) -5)

SUZ-KA50/KA60 type 20 g

%

(refrigerant piping length (m) -7)

SUZ-KA71 type 55 g

%

(refrigerant piping length (m) -7)

Piping preparation

• Refrigerant pipes of 3, 5, 7, 10 and 15 m are available as optional items.

(1) Table below shows the specifications of pipes commercially available.

(2) Ensure that the 2 refrigerant pipes are well insulated to prevent condensation.

(3) Refrigerant pipe bending radius must be 100 mm or more.

Caution:

Using careful insulation of specified thickness. Excessive thickness prevents

storage behind the indoor unit and smaller thickness causes dew drippage.

Pipe

For liquid

For gas

For liquid

For gas

For liquid

For gas

For liquid

For gas

For liquid

For gas

Outside diameter

mm

inch

6.35

1/4

9.52

3/8

6.35

1/4

9.52

3/8

6.35

1/4

12.7

1/2

6.35

1/4

15.88

5/8

9.52

3/8

15.88

5/8

Model

SUZ-KA25

SUZ-KA35

SUZ-KA50

SUZ-KA60

SUZ-KA71

Insulation

material

Heat resisting

foam plastic

0.045 specific

gravity

Insulation

thickness

8 mm

8 mm

8 mm

8 mm

8 mm

8 mm

8 mm

8 mm

8 mm

8 mm

Indoor unit

Outdoor unit

Fig. 5-1

:

6.35

:

9.52

:

9.52

:

12.7

:

15.88

Fig. 5-2

/

0

1

2

/

0

/

0

1

2

3

/

0

1

2

3

4

/

/

/

/

0

0

0

0

0

1

1

1

1

2

2

2

3

3

4

Indoor unit

Outdoor unit

Min. wall

thickness

0.8 mm

0.8 mm

0.8 mm

0.8 mm

0.8 mm

0.8 mm

0.8 mm

0.8 mm

0.8 mm

1.0 mm

+0

-0.4

Refrigerant to be

added

A

Fig. 5-4

(C)

(B)

(A)

90°