– 15 –

(6) Bearing noise

The easiest way to check a bearing is to listen to the noise it generates. Listen to the bearing noise during operation

so that abnormalities can be found at an early stage.

However, do not rely on the noise only to decide pass or fail. Check the vibration, temperature and discharged

grease so that you do not judge the practically all right parts to be defective.

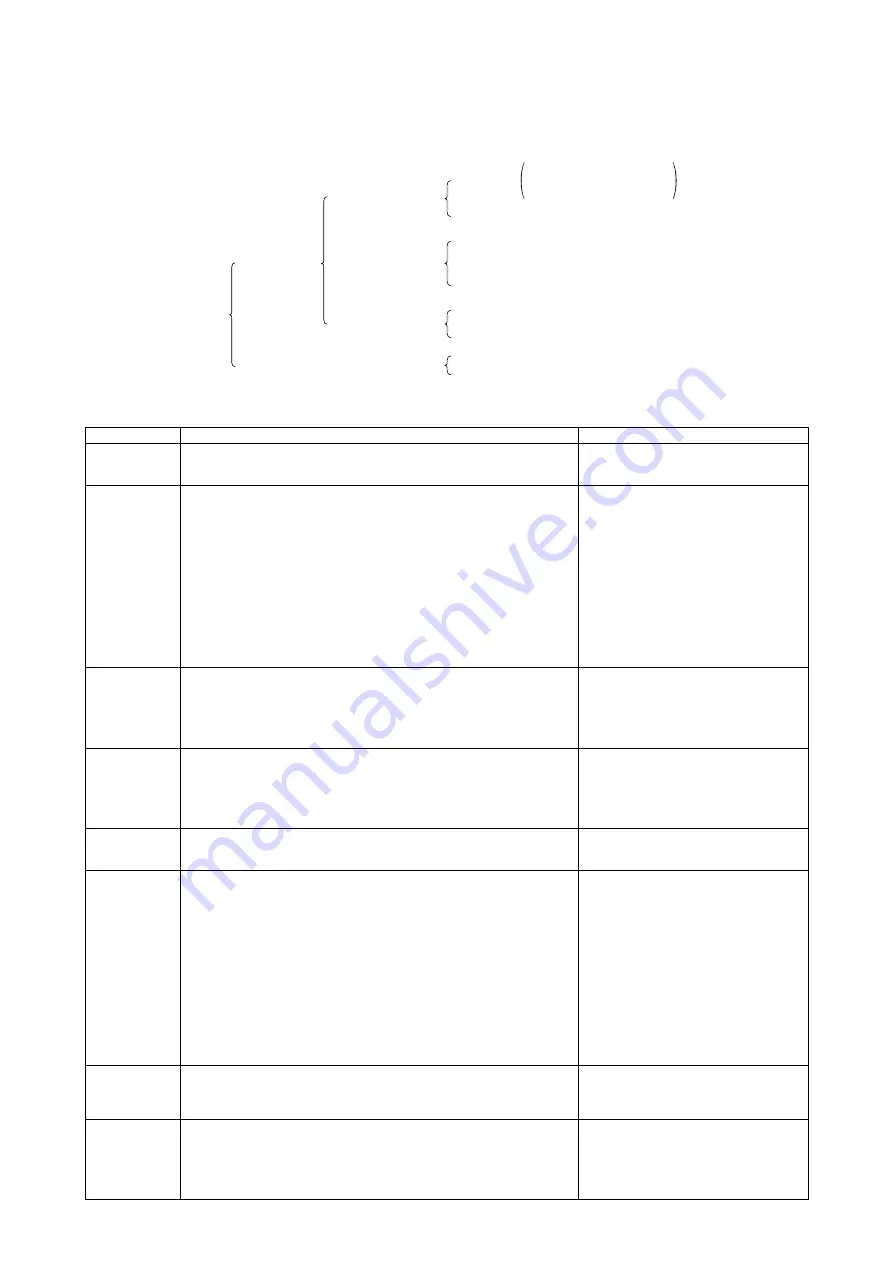

Noise related to

rolling bearing

Bearing noise

Noise when bearings are assembled

Motor groaning noise (Ball bearings and roller bearings)

Intricate noise

Noise related to

bearing manufacture

Noise related to

incorrect handling

of bearings

Race noise

All bearings

Mainly, single row deep

groove radial ball bearings

Squeaking noise (Roller bearings)

Retainer noise (Ball bearings)

Roller dropping noise (Roller bearings)

Chatter noise (All bearings)

Scratch noise (All bearings)

Dirt noise (All bearings)

Table 13

Cause of noise

Measures

Race noise

(normal noise)

This noise is characteristic of the rolling bearing and occurs in every

bearing. The noise is generated when the roller rolls over the locus due to

rotation of the bearings. This should be a smooth and continuous noise.

Normal noise

Squeaking noise

This is a "squeaking" noise generated by almost all roller bearings. It is a

metallic sound, and is caused by the non-uniform movement of the rolling

element in a no-load area. This noise has the following characteristics.

1) This noise is heard when grease lubrication is used, and is rarely

heard when oil is used.

2) This noise occurs easily when the lubrication performance

(especially oil) is poor.

3) This noise occurs easily during the winter.

4) This noise occurs easily when only a radial load is applied and the

radial clearance of the bearings is large.

5) This noise occurs at a certain rotating speed range, and the range

differs according to the size of the bearings.

(If this noise is heard, try replenishing a small amount of the designated

grease. This noise may occasionally be heard in ball bearings.)

• As long as the noise is not caused

by a heavy load, and is only due to

vibration or temperature, use can be

continued.

• Replenish the grease.

• Use bearings with a small radial

clearance.

• Use soft grease with a good oil

performance.

• Use a bearing for squeaking noise

measures.

Retainer noise

This noise is heard when the retainer vibrates during bearing rotation

and collides with the rolling element. The noise is cyclic and has the

following characteristics.

1) This noise is heard in both grease lubrication and oil lubrication.

2) This noise occurs easily in ball bearings having a large radial clearance.

3) This noise occurs easily when a moment is applied to the outer bearing ring.

• When using ball bearings, decrease

the radial clearance or apply a pre-

load.

• Use a lubricant with a good

lubrication performance.

• Replenish the grease.

Roller dropping

noise

This noise is generated due to the radial clearance and the relation of the

clearance between the retainer and rolling element. If the bearing is being used

in a horizontal rotor, this noise is generated when the balls drop faster than the

retainer due to the gravity of the rolling element when in a no-load area near

the top, and collide with the retainer. This noise is not heard during low speed

operation or normal operation, and often occurs just before stopping.

• This is not an abnormal noise.

• Decrease the radial clearance if

necessary.

Chatter noise

The bearings vibrate when there is a circular spiral having a relatively

large crest on the inner/outer race raceway surface or rolling surface. If

the speed is constant, this sound will have a constant frequency.

• Replace the bearings.

Scratch noise

A cyclic noise sounding like a riveter and vibration occur if the raceway

surface or rolling surface has scratches (scratches, indentation and rust).

The cycle may be constant if the speed is constant. The cycle becomes

longer as the rotating speed drops. As for ball bearings, if the scratch is

on the raceway surface, the noise may be continuous. However, if the

scratch is on the ball, the noise may not be heard. The noise, however, is

still cyclic. This noise may sound differently after replenishing grease.

The major causes and characteristics are as follows.

1) While the motor stands still, vibration from other equipment causes

the bearing raceway surface to be damaged by scratches. The

scratches are at the same spacing as the ball-to-ball spacing.

2) An excessive radial load and/or excessive vibration causes the

bearing raceway surface to be damaged by fretting or peeling.

3) The electrolytic corrosion while driven by an inverter causes the

bearing raceway surface to be damaged by striped pattern scratches.

• Replace the bearings.

• Investigate the cause of scratches.

• Do not give an excessive impact

or shock to the bearings during

assembling the bearing or transport

the motor.

• Isolate the motor from the machine so

as not to vibrate the other.

• Reduce the radial load or the

magnitude of vibration.

• Lower the carrier frequency of the

inverter.

• Install a filter.

Dirt noise

A non-cyclic noise is heard when there is dirt in the bearings.

1) When the bearings were not completely washed.

2) When foreign matter entered the lubricant.

3) When dirt entered the bearings during rotation.

• Wash the bearings.

• Replace the bearings.

Groaning noise

This noise is caused by a resonance of the natural vibration of the

vibration system composed of the ball bearings axial spring and rotor,

and the vibration system formed between this assembly and the

bracket. This is caused by the resulting unstable vibration.

• Use grease with a good lubrication

performance.

• Apply an appropriate pre-load.

• Decrease the radial clearance.

• Loosen the fitting of the outer ring.

• Increase the axial rigidity of the bracket.