– 19 –

b. Installation of open type ball bearings or roller bearings

(a) Put the bearing into a clean oil bath and heat it up to about 90°C for 30 minutes. Make absolutely sure that

the temperature does not by all means exceed 100°C. Put the heated bearing on the shaft. Do not move the

bearing until it has completely cooled down. Be sure to put on appropriate protective wears and devices so

as not to get burned when putting the bearing on the shaft. (Before putting the bearing on the shaft, assemble

the shaft box cover and other devices.)

(b) Do not attempt to tighten the lock nut or assemble the bearing on the bracket. Otherwise, the bearing may be

displaced. Make sure that the bearing has completely cooled down before starting the reassembling.

16

. TROUBLESHOOTING, SERVICING AND PRODUCT WARRANTY

(1) Commission all disassembly, reassembly and repairs of the motor to a specialist.

Modifications of the product by the user will not be covered by the Mitsubishi warranty.

(2) Common troubles and remedies are described in Table 16.

If the problem cannot be solved easily, or if there are any unclear points, consult Mitsubishi Sales Office, local agent

or service center.

Notify the following items when making inquiries on troubles or when purchasing spare parts.

a. The type (TYPE), output (kW), No. of poles (POLE), frame No. (FRAME), manufacturing No. (SERIAL) and

manufacturing date (DATE) listed on the motor nameplate.

b. Length of use.

c. Usage site.

d. Place and state of trouble.

e. Name and quantity of spare parts. (Refer to the "17. MOTOR CONSTRUCTION DRAWINGS" for the part

names.)

(3) Warranty period and coverage

a. As a principle, Mitsubishi shall bear the cost of repairs resulting from equipment problems for a period one year

after product delivery, or 18 months from the time of shipment, whichever is shortest.

b. This warranty covers the shipped product only. Responsibility for customer losses or compensation attributed to

breakdown of this product are not covered by the warranty.

c. For important machines, prepare spare machines or motors, or ensure the redundancy.

d. The product modified or repaired by the customer is not covered by the warranty.

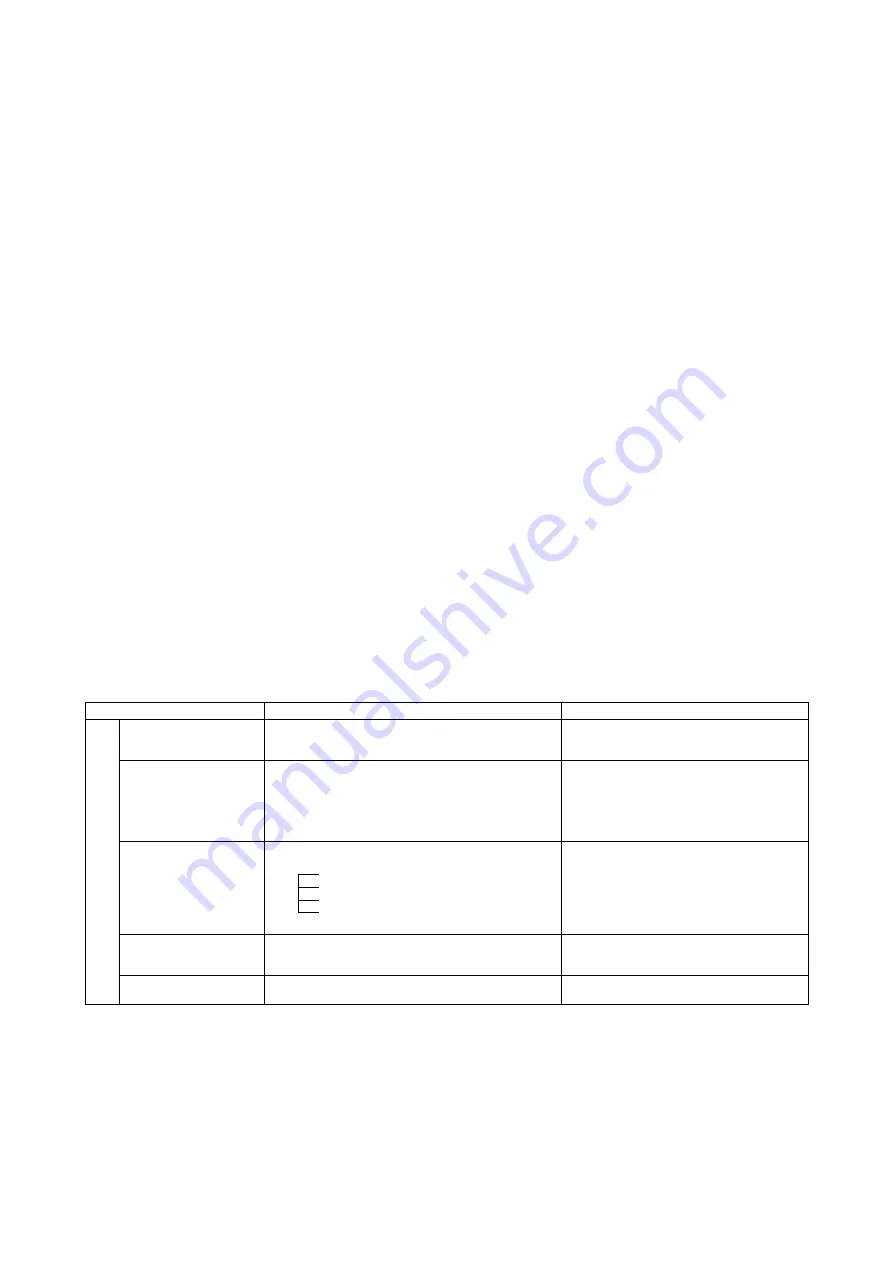

Table 16 Troubleshooting and remedial actions

Phenomenon

Cause

Remedy

T

he m

ot

or d

oe

s n

ot r

ot

at

e e

ve

n i

n t

he n

o

-l

oa

d s

ta

te

1. The motor can be

manually rotated in

either direction.

1. The switch or wire contact is faulty.

2. The fuse or a wire is broken.

3. The stator coil is faulty.

1. Adjust or replace the contact section.

2. Inspect and repair or replace.

3. Have specialist repair.

2. An abnormal noise

is heard. A groan

is heard. A groan is

heard when starting.

1. One phase is open causing a single phase state.

2. The switch or wire contact is faulty.

3. The fuse or a wire is broken.

4. The stator winding is faulty.

5. There is a constraint in the motor (bearing

damage, etc.)

1. Check the switch and power circuit.

2. Adjust or replace the contact section.

3. Inspect and repair or replace.

4. Have specialist repair.

5. Have specialist repair.

3. No noise is heard.

O

th

er t

ha

n

m

ot

or

:

1. The stator winding is faulty.

2. Each interlock release state is faulty.

3. Power failure.

4. The fuse or two wires are broken.

5. Two or more switches have a faulty contact.

6. Two or more starters have broken wires.

1. Have specialist repair.

2. Inspect the circuit.

3. Contact the power company.

4. Inspect and repair or replace.

5. Adjust or replace the contact section.

6. Inspect and repair the starter conductor

section.

4. Motor does

not rotate even

manually.

1. Stator and rotor completely contact.

2. Bearings are damaged.

1. Have specialist repair.

2. Have specialist repair.

5. The protection

device functions.

1. The terminal contact is faulty.

2. The stator winding is faulty.

1. Repair the contact section.

2. Have specialist repair.