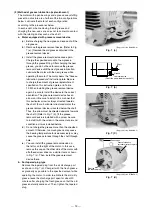

Installation bolt

(Nagoya Works B904138-1)

Fig. 1 Shaft protection clamp

– 2 –

3

. SHAFT PROTECTION CLAMP

A motor that uses roller bearings is equipped with the shaft

protection clamp so that the shaft displacement or vibration

during the transport would not damage the roller bearings.

(Refer to Fig. 1.)

Before hooking up the motor to a machine, loosen the

installation bolt to remove the installation hardware.

If you have to transport the machine with the motor connected

to it for delivery, be absolutely sure to remove the pulley and

other devices and install this shaft protection clamp. Or provide

the motor with some other means so as not to let the shaft be

displaced.

4

. INSTALLATION

Observe the following points as incorrect installation will shorten the motor's service life and can directly lead to

accidents.

a.

Always use an explosion-proof motor when using the motor in an explosive environment.

b.

When installing the motor outdoors, always use the outdoor type motor (IP44). If the installation

environment is severe, use a water-proof and dust-proof motor (IP55). For the details, contact us.

c. The standard motor is not adequate for use in an acidic or alkaline environment. For use in this type of environment,

contact Mitsubishi for a corrosion proof motor.

d.

When installing the motor on a ceiling or wall, it could fall depending on the circumstances. Refer to the

catalog or technical documents for details on the applicable range.

e.

Install a cover, etc., as a means to prevent foreign matter entering or persons touching the coupling, belt or

pulley that couple the motor and partner machine.

f. Avoid installing the motor in a high-humidity, high-dust, high-temperature place where water or oil may come in

contact. Select a well-ventilated, clean, dry environment.

g. Note that if the motor is used in a dusty area, the heat radiation effect (cooling effect) of the motor may be degraded,

resulting in rise of motor temperature, or dust may enter the bearings, thereby causing abnormal noise and damage.

h. If the motor is installed near a wall or near other devices, the motor's cooling path will be blocked causing the motor

to overheat.

Always provide a space (generally 20cm or more) when installing the motor.

i. Select a place where the motor can be easily serviced and inspected.

j. To install, embed the motor in a concrete foundation or secure the motor to a rigid steel structure or wooden frame

so that the shaft will always be horizontal. (When installing the vertical motor, make sure that the shaft is vertical and

the shaft end is facing down.) Always install special motors according to the specifications. Most cases of abnormal

motor vibration are caused by a weak foundation or incorrect coupling with the partner machine. Make sure to

correctly install and couple the motor.

k.

Do not place flammable matters around the motor.

l.

Never get on or hang from the motor.

m.

Make sure that the nameplate is always visible. Do not place obstacles near the nameplate or remove the

nameplate.

n. The outdoor type motor has a drain hole, etc. on its bottom. Install the motor in the position shown in the outline

drawing or final diagram. The standard structure of the shaft through hole on the load side of the outdoor flange type

motor is not sealed. Ensure the water-tightness of the flange joints.

o. After connecting with the machine, treat the machined motor shaft surfaces with a rust-preventive agent to prevent

the motor shaft from rusting.