MODELS: WT-46809 / WS-55809 / WS-55819 / WS-65809 / WS-65819

Page 3

INTRODUCTION ................................................................................................................................ 5

PRODUCT SAFETY NOTICE ............................................................................................................. 5

SAFETY PRECAUTIONS ................................................................................................................... 6

DISASSEMBLY

Cabinet Disassembly (Front View) ..............................................................................................

7

WT-46809 .............................................................................................................................. 7

WS-55809 / WS-65809 .......................................................................................................... 8

WS-55819 / WS-65819 .......................................................................................................... 9

Cabinet Disassembly (Rear View) .............................................................................................

10

WT-46809 ............................................................................................................................ 10

WS-55809 / WS-55819 / WS-65809 / WS-65819 ................................................................. 11

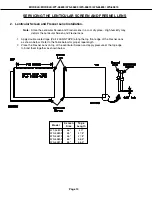

SERVICING THE LENTICULAR SCREEN AND FRESNEL LENS

Lenticular Screen and Fresnel Lens Remova

l ......................................................................... 12

WT-46809 / WS-55809 / WS-65809 ..................................................................................... 12

WS-55819 / WS-65819 ........................................................................................................ 13

Lenticular Screen and Fresnel Lens Installation ....................................................................

14

SERVICING THE DIAMONDSHIELDS

TM

r

DiamondShield

TM

Removal & Installation ...................................................................................... 15

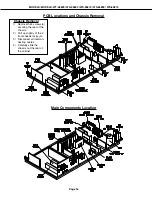

SERVICING PCBs

Chassis Removal .......................................................................................................................... 16

PCB Locations .............................................................................................................................. 16

Main Components Location ........................................................................................................... 16

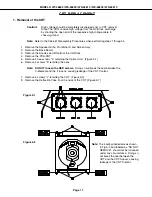

CRT REPLACEMENT

CRT Removal ................................................................................................................................ 17

CRT Installation ............................................................................................................................ 18

ELECTRICAL ADJUSTMENTS

Test Equipment ............................................................................................................................. 20

Initial Setup ................................................................................................................................... 21

LED Indicator Diagnostics ............................................................................................................. 22

Circuit Adjustment Mode ............................................................................................................... 22

Convergence Adjustment Mode ..................................................................................................... 24

E2PROM Replacement ................................................................................................................. 27

Adjustment Items List ................................................................................................................... 27

Adjustment Test Points ................................................................................................................. 30

Adjustment Procedures ................................................................................................................ 31

Audio Circuit ........................................................................................................................ 31

High Voltage Regulation ....................................................................................................... 32

Main/Sub Y Level ................................................................................................................. 32

Side by Side Sub Picture Tint .............................................................................................. 33

Side by Side Sub Picture Color ............................................................................................ 33

CRT Cutoff ........................................................................................................................... 34

White Balance (NTSC) ......................................................................................................... 34

White Balance (HD) ............................................................................................................. 35

Cb, Cr Offset ........................................................................................................................ 35

Black Level .......................................................................................................................... 36

Sub Contrast ....................................................................................................................... 36

CONTENTS

Summary of Contents for WS-55809

Page 2: ......

Page 60: ...MODELS WT 46809 WS 55809 WS 55819 WS 65809 WS 65819 Page 60 STANDBY SUPPLIES REGULATOR ...

Page 61: ...MODELS WT 46809 WS 55809 WS 55819 WS 65809 WS 65819 Page 61 SWITCHED SUPPLIES REGULATOR ...

Page 62: ...MODELS WT 46809 WS 55809 WS 55819 WS 65809 WS 65819 Page 62 VIDEO COLOR A V SWITCH CIRCUIT ...

Page 63: ...MODELS WT 46809 WS 55809 WS 55819 WS 65809 WS 65819 Page 63 PCB SIGNAL Y C PATH ...

Page 64: ...MODELS WT 46809 WS 55809 WS 55819 WS 65809 WS 65819 Page 64 SYNC PATH ...

Page 65: ...MODELS WT 46809 WS 55809 WS 55819 WS 65809 WS 65819 Page 65 DEFLECTION CIRCUIT X RAY PROTECT ...

Page 66: ...MODELS WT 46809 WS 55809 WS 55819 WS 65809 WS 65819 Page 66 SOUND CIRCUIT ...

Page 67: ...MODELS WT 46809 WS 55809 WS 55819 WS 65809 WS 65819 Page 67 CONVERGENCE CIRCUIT ...

Page 68: ...MODELS WT 46809 WS 55809 WS 55819 WS 65809 WS 65819 Page 68 CONTROL CIRCUIT ...

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......