Page 26

Purpose:

Measuring

Instrument

Test Point

Measuring

Range

Input Signal

Ext. Trigger

Input Terminal

Symptom:

Purpose

Measuring

Instrument

Test Point

Measuring

Range

Input Signal

Ext. Trigger

Input Terminal

Symptom:

MODEL: WT-42313 / WT-42413

[Video Circuit]

Oscilloscope

JA pin 18

JA pin 8

------

------

Color Bars

Video

To match the sub picture color to that of the main picture.

Main and sub pictures colors differ.

1. Supply an NTSC signal to an External Video Input.

2. Select the NTSC signal as the source for both the main and sub pictures.

3. Connect an oscilloscope to connector JA pin 18 (Main PR).

4. Activate the Adjustment mode.

5. Select Item “2 COLM” in the Main Matrix Function.

6. Adjust data so the PR signal is 0.71 Vp-p max. - 0.66 Vp-p min

(If it cannot be adjusted within this range, set to the lower value)

7. Connect an oscilloscope to connector JA pin 8 (Sub PR). If the waveform is

unstable, activate PIP.

8. Select item “2 COLS” in the Sub Matrix Function.

9. Adjust so Sub PR = Main PR.

3. Main/Sub Color Level

To set the cutoff point for all three CRTs.

Monochrome has a color tint, or incorrect brightness.

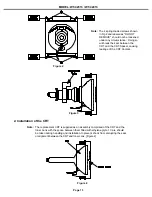

[CRT Circuit]

4. CRT Cutoff

Oscilloscope

TP6R, TP6G, TP6B

------

50V/Div. 2msec/Div.

None

Video Input

Note

:

Use the Expand mode (full screen)

1. Select an External Input with no signal.

2. Enter the Adjustment Mode, Video Chroma Function.

3. Press “1”, automatically blanks the screen and sets COL to 0.

Note:

If the screen goes blue, turn off Video Mute.

4. Set the data to the values given in the table below.

5. Connect the oscilloscope to TP6R.

6. Adjust the Red Screen VR so the black level is 170V, as shown below, or

176V ±1VDC using an DC Voltmeter.

7. Repeat Steps 4 and 5 to set the Blue and Green Screen VRs, using

TP6G and TP6B.

Note:

White Balance must be performed after this adjustment.

Item

Abbr

Data

1

SCT

31

2

SBRT

31

3

SCON

0

4

RDRH

31

5

GDRH

41

6

BDRH

31

7

CTRH

31

8

CTGH

46

9

CTBH

31

Cutoff Preset VC Data

CIRCUIT ADJUST MODE

Activate …….. MENU-0-3-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

CIRCUIT ADJUST MODE

Activate …….. MENU-0-3-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

Summary of Contents for WT-42313

Page 2: ......

Page 11: ...MODEL WT 42313 WT 42413 Page 11 PCB Locations Major Parts Locations ...

Page 53: ...MODEL WT 42313 WT 42413 Page 53 POWER SUPPLY ...

Page 54: ...MODEL WT 42313 WT 42413 Page 54 VIDEO COLOR ...

Page 55: ...MODEL WT 42313 WT 42413 Page 55 SYNC SIGNAL PATH ...

Page 56: ...MODEL WT 42313 WT 42413 Page 56 DEFLECTION HV ...

Page 57: ...MODEL WT 42313 WT 42413 Page 57 HV REGULATION ...

Page 58: ...MODEL WT 42313 WT 42413 Page 58 X RAY PROTECT ...

Page 59: ...MODEL WT 42313 WT 42413 Page 59 SOUND SIGNAL PATH ...

Page 60: ...MODEL WT 42313 WT 42413 Page 60 CONVERGENCE ...

Page 61: ...MODEL WT 42313 WT 42413 Page 61 CONTROL CIRCUITRY ...