–

36

–

Code

No.

Write contents

Record data

Data write range

Unit of

write

Number of

bytes

Contents

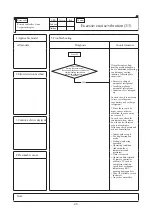

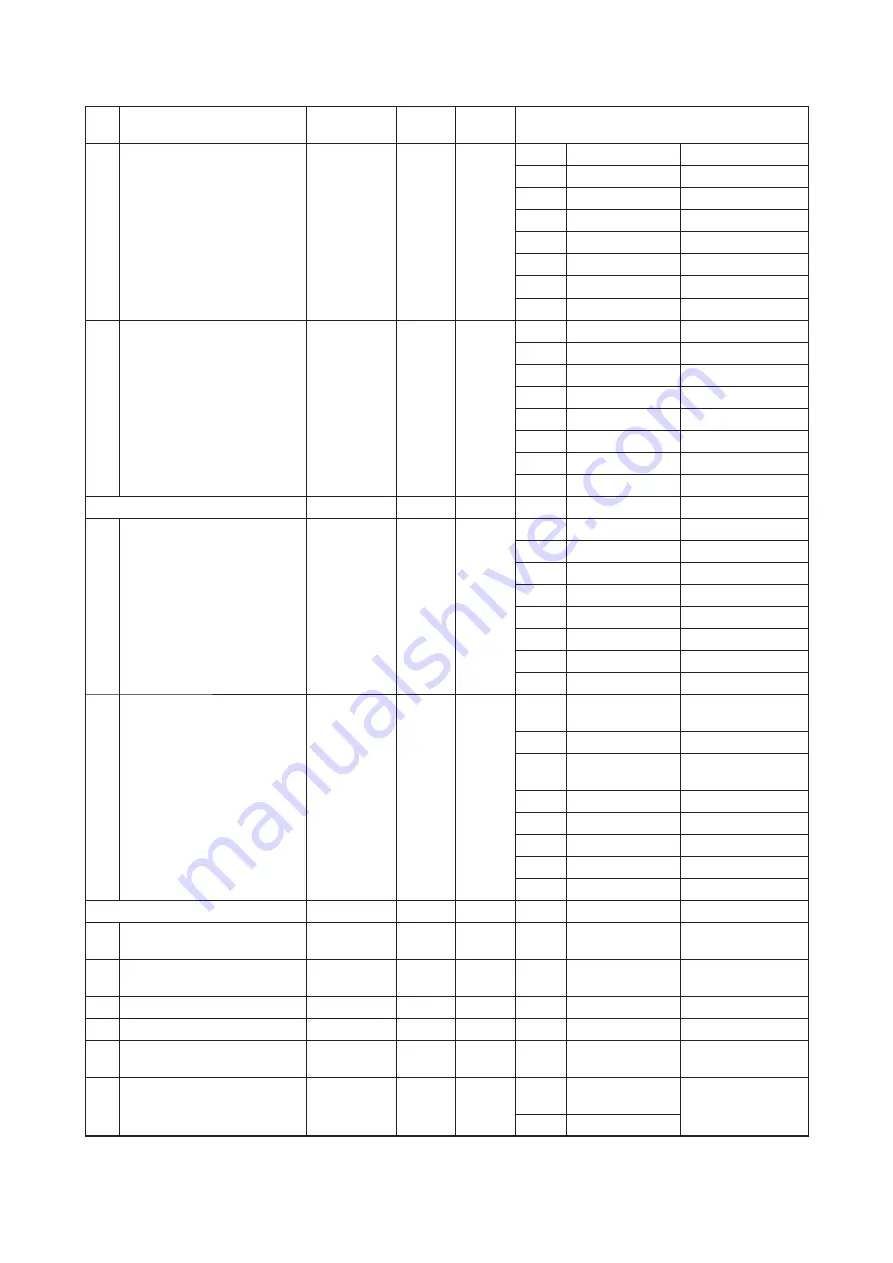

52 Dip SW [SW6]

–

–

1

Bit0

SW6-1

0 : OFF, 1 : ON

Bit1

SW6-2

0 : OFF, 1 : ON

Bit2

SW6-3

0 : OFF, 1 : ON

Bit3

SW6-4

0 : OFF, 1 : ON

Bit4

SW6-5

0 : OFF, 1 : ON

Bit5

SW6-6

0 : OFF, 1 : ON

Bit6

SW6-7

0 : OFF, 1 : ON

Bit7

SW6-8

0 : OFF, 1 : ON

53 Jumper SW

–

–

1

Bit0

J11

0: Open, 1: Short-circuit

Bit1

J12

0: Open, 1: Short-circuit

Bit2

J13

0: Open, 1: Short-circuit

Bit3

J14

0: Open, 1: Short-circuit

Bit4

J15

0: Open, 1: Short-circuit

Bit5

J16

0: Open, 1: Short-circuit

Bit6

(Spare)

Bit7

(Spare)

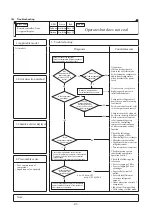

<PCB hardware output>

54 Relay output

–

–

1

Bit0

52X1, 52X2

0 : OFF, 1 : ON

Bit1

20S

0 : OFF, 1 : ON

Bit2

CH1

0 : OFF, 1 : ON

Bit3

SV1

0 : OFF, 1 : ON

Bit4

SV6

0 : OFF, 1 : ON

Bit5

SV11

0 : OFF, 1 : ON

Bit6

(Spare)

0 : OFF, 1 : ON

Bit7

(Spare) FMC1,2

0 : OFF, 1 : ON

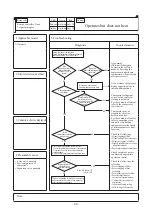

55 Relay output

–

–

1

Bit0

Operation output

(CnH)

0 : OFF, 1 : ON

Bit1

Error output (CnY) 0 : OFF, 1 : ON

Bit2

External output

(CnZ)

0 : OFF, 1 : ON

Bit3

(Spare)

0 : OFF, 1 : ON

Bit4

(Spare)

0 : OFF, 1 : ON

Bit5

(Spare)

0 : OFF, 1 : ON

Bit6

(Spare)

0 : OFF, 1 : ON

Bit7

(Spare)

0 : OFF, 1 : ON

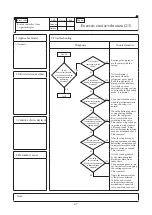

<Related to compressor>

56 CM1 Cumulative operation

hours (Approx.)

0 ~ 65535

1h

2

57 CM1 Starting times

0 ~ 65535

× 20

times

2

58 CM1 3-minute delay timer

0 ~ 180

1 sec

1

59 Energizing time count down

0 ~ 255

1 min

1

60 Control status CH

Compressor protection timer

0 ~ 360

3 min

1

61 Control status CH

Compressor protection start

0 ~ 15

–

1

15

Protection start

complete

0 ~ 14 Protection start ON

Summary of Contents for 112KXE6

Page 105: ... 101 Model FDC335KXE6 A PCB003Z035 shows local wining ...

Page 134: ... 130 PJF012D003 ...

Page 135: ... 131 ...

Page 139: ... 135 PJA012D751 b ...

Page 140: ... 136 ...

Page 206: ... 202 2 model type DIS model type HEAD ...

Page 207: ... 203 2 2 ...

Page 208: ... 204 2 2 2 2 2 ...