–

33

–

(8) Pump down operation control at removal of unit

When an outdoor unit is discarded or removed, the pump down control is performed at the outdoor unit side in order to recover

the refrigerant quickly to the outdoor unit.

(a) Starting conditions

This is implemented with the liquid service valve closed.

(i) Outdoor unit operation mode – Stop

(ii) Turn ON the test run cooling switch SW5-2 (cooling).

(iii) Turn ON the pump down switch SW5-3 (pump down).

(iv) Turn ON the test run switch SW5-1 when the above (i)-(iii) statuses are satisfied.

Note (1) Input before the power ON is invalid.

(b) Control contents

(i) Compressor starts under compressor start protection control and runs at target speed of pump down operation.

However, when the operation starting conditions have been established during the 3-minute delay control of

compressor, the compressor starts after completing the 3-minute delay control.

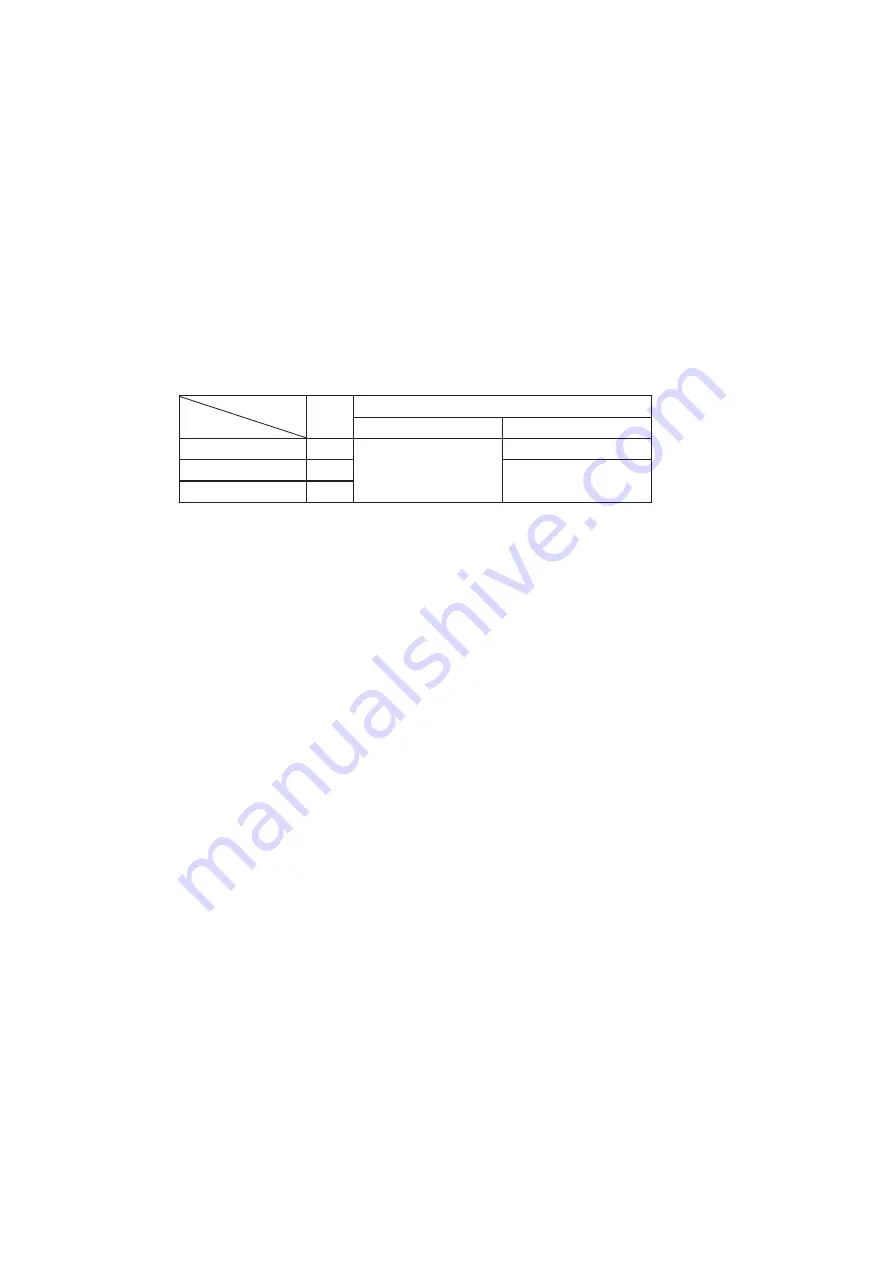

Item

Model

Hp

Target compressor speed at pump down operation

Number of compressors

Compressor speed

FDC112KXZEN/S1

4

1

37rps

FDC140KXZEN/S1

5

45rps

FDC155KXZEN/S1

6

(ii) As the starting conditions are established, both red LED and green LED on the outdoor PCB flash continuously.

7-segment display shows “PdS” (Channel 0) at the code display area.

(iii) During the pump down operation control, the protective controls (excluing low pressure protective control,

anomalous low pressure control and pressure ratio protection control) and the error detection control are effective.

(iv) The sub-cooling coil expansion valve (EEVSC) closes fully during the pump down control.

(c) Ending conditions

If any of the following conditions is satisfied, this control ends.

(i) If a low pressure (LP) ≤ 0.01MPa is detected for 5 seconds continuously, it ends normally and initiates the

followings.

➀

Red LED: keeps lighting

➁

Green LED: keeps flashing

➂

7-segment display: PdE

➃

Remote control: Stop

(ii) Anomalous all stop by the error detection control

(iii) If the cumulative compressor operation time under the pump down control totals 15 minutes (ending by time count

up), it stops and initiates the following.

➀

Red LED: stays OFF

➁

Green LED: keeps flashing

➂

7-segment display: No display

➃

Remote control: Stop

(iv) When any of setting switches (SW5-1, SW5-2 and SW5-3) has been turned OFF during pump down.

(Note) Even if only the pump down switch SW5-3 is turned OFF, it does not recognized as the cooling test run mode , but stops.

'17 • KX-SM-272

Summary of Contents for 140KXZEN1

Page 153: ... 17 KX SM 272 151 ...

Page 154: ... 17 KX SM 272 152 ...

Page 155: ... 17 KX SM 272 153 ...

Page 156: ... 17 KX SM 272 154 ...

Page 165: ... 163 MEMO 17 KX SM 272 ...