16

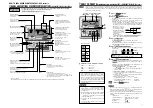

MAINTENANCE AND INSPECTION GUIDELINE OF MAIN PARTS OF PACKAGED AIR CONDITIONER

This table indicates the details of regular inspection items and their intervals

(inspection interval), and the timing of parts replacement under a normal

use condition. If the equipment falls into a certain category specifi ed by the

laws and regulations of each country, conduct the maintenance and inspection

according to the specifi ed rules too. As to the preventive maintenance, the

regular inspection interval is indicated as the “inspection interval,” and the

predicted interval of the “implementation of cleaning and adjustment” or

“implementation of parts replacement and repair” according to the result of the

regular inspection is indicated as the “maintenance interval.” As to the cleaning

and adjustment, the timing is set to prevent the deterioration of parts and the

degradation of performance. As to the parts replacement and repair after the

inspection, the timing is set by estimating the operation time or use time, when

the wear-out failure period is reached.

Note 1) Random fault is an unexpected failure which occurs before the wear

is progressed, within the service life of the parts and equipment. It is

difficult to establish a technological measure against the random fault.

At the moment, statistical handling is the only measure against the

random fault.

Note 2) The elapsed year marked with * assumes the operating time as 10

hours/day and 2500 hours/year in a normal operating condition

without frequent start/stop. This may vary according to the operating

condition. Please check the calculation basis of the elapsed year when

making a maintenance contract.

Note 3)

illustrates the estimated timing when the wear-out

failure starts and how the failure rate increases as the time passes.

Note 4) The inspection timing of fi lter is basically every week. However, the

contamination state varies depending on the type of fi lter and the

use condition. Therefore, conduct the inspection in arbitrary cycles

according to the use condition.

[Mainly

indoor

parts and built-in components]

*The distinction between the indoor and outdoor assumes the air conditioner for a store and a multiple-air conditioner for a building. This may vary depending on the configuration of the unit, such as equipment air conditioner.

Part Name

Regular Inspection

Preventive Maintenance*

Remarks

Part Name

Details of Inspection

Inspection Method

Criteria <Standard>

Details of Maintenance

Inspection

Interval

Maintenance Interval

(Used Hours/Duration)

Elapsed Years

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Structural

component

Decorative panel

(design part)

- Check of dirt and scratch

Visual inspection

- There should be no extreme dirt, scratches, or

deformation

- Cleaning with neutral detergent, paintwork by repair

coating

Every year

Before the air-

conditioning

season

8 years

S

Cleaning object item

Intake/outlet grills

- Visual check of dirt and scratch

- Outlet grill louver operation check

Visual inspection

- There should be no extreme scratches or deformation - Repair or replace it if deformed or damaged

- Replace the bearing, motor, etc. when malfunctioning

8 years

z

Frame, bottom

plate, etc.

- Check of rust and peeling off of the heat insulation

material

- Check of peeling off and fl oating of paint coating

Visual inspection

- There should be no extreme rust or damage of heat

insulation material

- If the heat insulation material is peeled off, repair and

stick it

- Paintwork by repair coating

8 years

S

Cleaning object item

Vibration-proof

rubber

- Check of deterioration and hardening of rubber

Visual and audible

inspection

- Vibration insulation function should not be impaired - Replace it when deteriorated or hardened

10 years

S

Ventilation

system parts

Filter

- Visual check of dirt and breakage

Visual inspection

- Filter material should be seen through

- There should be no breakage or deformation

- Clean it if it is dirty

- Replace it if it is broken

Every week

Note 4

5 years

Consumable

components

Fan

Fan casing

- Visual check of vibration and balance

- Check of dust adhesion and appearance

Visual inspection

Visual inspection

- Should not be in an extremely vibrating condition

- There should be no extreme rust or deformation

- Replace it in case of vibration and extreme unbalance

- Clean with a brush or wash with water in case of

extreme dust adhesion

Every year

Before the air-

conditioning

season

13 years

z

Fan motor

- Sound audibility check

- Insulation resistance measurement

Audible inspection

500 V mega

- There should be no abnormal sound generation

- The resistance value should be 1 M

Ω

or more

- When a bearing sound is loud, replace the bearing

- When the resistance value is 1 MΩ or less, replace the

motor

20,000 Hr

S

Bearing

- Regular lubrication is required

Audible inspection

- There should be no abnormal sound generation

- Replace parts regularly

15,000 Hr

Consumable

components

Automatic louver

motor

- Insulation resistance, abnormal sound generation

500 V mega, audible

inspection

- The resistance value should be 1 M

Ω

or more,

there should be no abnormal sound

- Replace it if the resistance value is 1 M

Ω

or less

20,000 Hr

S

Drain system

parts

Drain pan

- Check the clogging of foreign matters and the fl ow of

drain water

- Check of peeling off and fl oating of paint coating

Visual inspection

- There should be no drainage clogging

- There should be no abnormal rust generation and

hole opening

- Cleaning of drain pan, inclination check

- Repair coating or replace the drain pan depending on

the problem level

8 years

S

Cleaning object item

Drain pump

- Check the drainage condition

- Check the clogging and dirt of the water supply and

drainage outlet

- Insulation resistance

Visual inspection

Visual inspection

500 V mega

- Should be drained normally

- There should be no clogging or dirt

- The resistance value should be 1 M

Ω

or more

- Replace it in case of drain defect

- Clean it in case of clogging and dirt

- Replace it if the resistance value is 1 M

Ω

or less

20,000 Hr

S

Dewing preventing

heater

- Insulation resistance, appearance check

500 V mega, visual

inspection

- The resistance value should be 1 M

Ω

or more,

there should be no abnormality

- Replace it if the resistance value is 1 M

Ω

or less

20,000 Hr

S

Float switch

- Operation check

Tester

- ON-OFF should operate normally

- Replace it in case of malfunction

20,000 Hr

S

Refrigerant

system parts

Air heat exchanger

- Check the clogging and damage due to foreign

objects

- Gas leakage

Visual inspection

Gas detector

- There should be no clogging or damage

- No leakage should be detected

- Wash the air infl ow side in case of clogging

- Repair or replace it when gas leakage is detected

5 years

z

z

z

z

z

Cleaning object item

Due to atmospheric

dirt

Piping in the unit

- Sympathetic vibration, contact, and corrosion of the

piping in the unit

- Sympathetic vibration and contact of capillary tube

Visual inspection

Visual inspection

- There should be no abnormal sympathetic vibration,

sound, or corrosion

- There should be no abnormal sympathetic vibration

or contact wear

- Replace it or readjust the piping when extremely

corroded

- Replace it or readjust the piping when extremely

worn

20,000 Hr

S

Electronic expansion

valve

- Operation check

- Operation sound by power on/off (pressure check)

Tactile inspection

Audible and tactile

inspection

- Circulation of refrigerant should be felt

- There should be driving sound and temperature

change

- Replace it when locking occurs

20,000 Hr

S

Electromagnetic

valve, four way

switching valve, etc.

- Operation and insulation performances of

electromagnetic valve, four way switching valve, etc.

- Corrosion, abnormal sound

500 V mega

Visual and audible

inspection

- The resistance value should be 1 M

Ω

or more

- There should be no abnormal sound or corrosion

- Replace it if the resistance value is 1 M

Ω

or less

20,000 Hr

S

Electric and

electronic parts

Electric component

box

(including inverter)

- Circuit insulation resistance check

- Terminal part, connector looseness check

500 V mega

Driver, visual inspection

- The resistance value should be 1 M

Ω

or more

- There should be no looseness at the connecting

part

- There should be no deposited foreign matter

- There should be no abnormal display

- Clean with a brush in case of extreme dust adhesion

- Replace it if the resistance value is 1 M

Ω

or less

- Retighten or reinsert it if there is looseness

25,000 Hr

S

Switching power

source transformer

- Output voltage measurement

Tester

- Output voltage should be within a specifi ed value

- Replace it if there is voltage abnormality

10 years

S

Temperature sensor

Humidistat

- Open, short circuit, earth, appearance check

Tester, visual inspection - Should be of a specifi ed resistance value

- There should be no cracking or discoloration

- Replace it in case of disconnection and short circuit

5 years

S

Remote control

switch

- Check the controllability by the operation

Visual inspection

- LCD should display as operated

- Replace it in case of failure of the following capability

of control and the display

25,000 Hr

S

Explanation of symbols

z

: Conduct the cleaning and adjustment according to the inspection result

S

: In case of abnormality after inspection, replace or repair the corresponding part.

: Conduct the periodic replacement (consumable components)

: Random failure

: Wear-out failure

Summary of Contents for FD Series

Page 2: ......