18

Explanation of symbols

z

: Conduct the cleaning and adjustment according to the inspection result

S

: In case of abnormality after inspection, replace or repair the corresponding part.

: Conduct the periodic replacement (consumable components)

: Random failure

: Wear-out failure

Part Name

Regular Inspection

Preventive Maintenance*

Remarks

Part Name

Details of Inspection

Inspection Method

Criteria <Standard>

Details of Maintenance

Inspection

Interval

Maintenance Interval

(Used Hours/Duration)

Elapsed Years

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Electric and

electronic

parts

Crankcase heater

- Conductivity check

- Insulation resistance measurement

- Appearance check

Tester

500 V mega

Visual inspection

- It should be in a conducting state

- The resistance value should be 1 M

Ω

or more

- There should be no abnormality

- Replace it if it is not in a conducting state

- Replace it if the resistance value is 1 M

Ω

or less

Every year

Before the air-

conditioning

season

8 years

Consumable

components

Anti-freezing heater

- Conductivity check

- Insulation resistance, appearance check

Tester

500 V mega, visual

inspection

- It should be in a conducting state

- The resistance value should be 1 M

Ω

or more,

there should be no abnormality

- Replace it if it is not in a conducting state

- Replace it if the resistance value is 1 M

Ω

or less

20,000 Hr

S

Electric component box

(including inverter)

- Circuit insulation resistance check

- Terminal part, connector looseness check

500 V mega

Driver, visual inspection

- The resistance value should be 1 M

Ω

or more

- There should be no looseness at the connecting

part

- Clean with a brush in case of extreme dust adhesion

- Replace it if the resistance value is 1 M

Ω

or less

- Retighten or re-insert it if there is looseness

25,000 Hr

S

Electrolytic

capacitor

- Capacitor (electrolytic) appearance check

Visual inspection

- There should be no liquid leakage or deformation

- Appearance check, replace it if there is liquid leakage

Smoothing

capacitor

- Measurement of electrical capacitance and insulation

resistance

- Appearance check

Electrostatic instrument,

500 V mega Tester

- Should be of specifi ed volume or more

- The resistance value should be 1 M

Ω

or more

- Replace parts regularly

- Replace it if the resistance value is 1 M

Ω

or less

10 years

Consumable

components

Terminal block

- Terminal part screw looseness, deposit of dirt

Driver, visual inspection - It should not be loose

- There should be no deposited foreign matter

- Retighten it if it is loose.

- Clean with a brush in case of deposited foreign matter

adhesion

25,000 Hr

S

Electrical

component

(including

boards, etc.)

- HIC board short circuit check

- Visual check of dirt adhesion to the board, etc.

- Self-diagnosis mode, appearance check

Tester

Visual inspection

Visual inspection

- Should be of a specifi ed resistance value

- There should be no deposited foreign matter

- There should be no abnormal display

- Replace it if it is outside the specifi ed resistance value

- Clean with a brush in case of deposited foreign matter

adhesion

- Replace or correct the part

25,000 Hr

S

Pressure sensor, temperature

sensor

- Open, short circuit, earth, appearance check

Tester, visual inspection - Should be of a specifi ed resistance value

- There should be no cracking or discoloration

- Replace it in case of disconnection and short circuit

5 years

S

Switch, etc.

(including

FFB, ELB)

Electromagnetic

switch

Overcurrent relay

Auxiliary relay, etc.

- Operation, appearance check

- Rough contact surface

Visual inspection

Visual inspection

- There should be no deformation

- It should operate as prescribed, there should be no

deformation

- There should be no deformation or discoloration

- Replace it in case of malfunction, deformation, and

discoloration

25,000 Hr

S

Switching power source

transformer

- Output voltage measurement

Tester

- Output voltage should be within a specifi ed value

- Replace it if there is voltage abnormality

10 years

S

Cooling fan

- Insulation resistance, abnormal sound generation

500 V mega, audible

inspection

- The resistance value should be 1 M

Ω

or more,

there should be no abnormal sound

- Replace it if the resistance value is 1 M

Ω

or less

- Replace it in case of fan lock

20,000 Hr

S

Fuse

- Appearance check

Visual inspection

- There should be no deformation or discoloration

- Replace it when it is shutdown

10 years

Consumable

components

Note 1) Random fault is an unexpected failure which occurs before the wear

is progressed, within the service life of the parts and equipment. It is

difficult to establish a technological measure against the random fault.

At the moment, statistical handling is the only measure against the

random fault.

Note 2) The elapsed year marked with * assumes the operating time as 10

hours/day and 2500 hours/year in a normal operating condition

without frequent start/stop. This may vary according to the operating

condition. Please check the calculation basis of the elapsed year when

making a maintenance contract.

Note 3)

illustrates the estimated timing when the wear-out

failure starts and how the failure rate increases as the time passes.

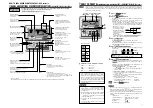

Summary of Contents for FD Series

Page 2: ......