-

21

-

(4)

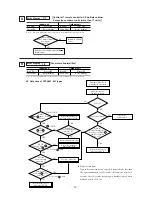

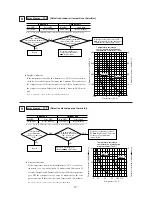

Error diagnosis procedures at the outdoor units side

At the error diagnosis related to the outdoor unit, check at first the error code of remote controller and the illumination patterns of

norma1 and inspection display lamps in the same manner as the case of indoor unit.

Then estimate the outline, the cause and the location of error based on the pattern and proceed to the inspcetion and repair.

Since the self diagnosis function by means of the microcomputers of indoor/outdoor units provide the judgement of error of

microcomputers them selves irregularity power supply line, overload, etc. caused by the installation space, inadequate volume of

refrigerant etc., the location and cause of trouble will be discovered without difficulty.

In addition, the display lamps error code of indoor/outdoor unit is kept flashing, (except when the power supply is iterrupted) after

the irregularity is automatically recovered to give irregularity information to the service presonnel. If any mode of higher priority

than the error retained in memory occurs after the reset of error, it is switched to that mode and saved in the memory.

(a)

Replacement parts assembly related to the outdoor unit controller

Outdoor unit PCB, power transistor module, capacitor, noise filter, thermistor, (heat exchanger, discharge pipe, outdoor

temperature, power transistor), fuse, transformer, etc.

(b) Replacement procedure of outdoor unit microcomputer printed circuit board.

Microcomputer printed circuit board can replaced with following procedure.

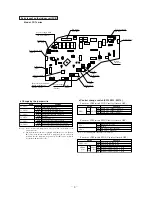

1) Confirm the parts numbers. (Refer to the following parts layout drawing for the location of parts number.)

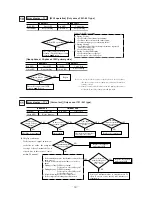

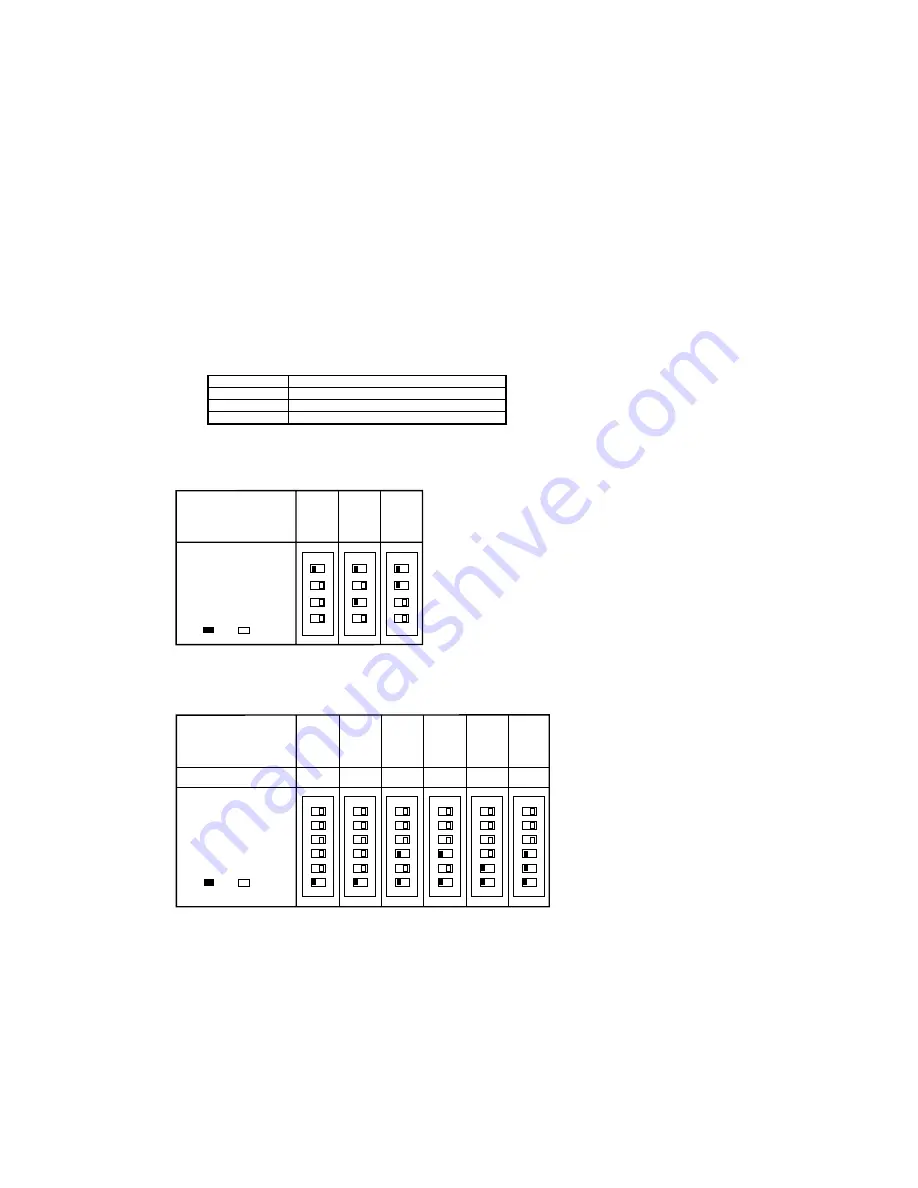

Applicable Model

FDCVA151HEN, 201HEN, 251HEN

FDCA301HEN, 401HEN

FDCA301HES, 401HES, 501HES, 601HES

PCA505A080Z

PCA505A065ZN

PCA505A065ZS

Parts No.

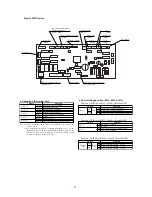

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

17

27

10

Switch Setting Table

Set the switches ON or

OFF for each switch

No.

( ON, OFF)

Model

Setting Value (A)

301HEN 301HES 401HEN

11

14

12

401HES 501HES 601HES

Switch Setting Table

Set the switches ON or

OFF for each switch

No.

( ON, OFF)

Model

151

201

251

1 2 3 4

ON

ON

ON

1 2 3 4

1 2 3 4

2) Set the model using the model setting switch (SW6). (In the case of the 151~251 only).

Switch Setting Table (All switches are set in the OFF position when shipped from the factory.)

3) Set the overcurrent value using the overcurrent setting switch for CM (SW3). (In the case of the 301~601 only)

Switch Setting Table (All switches are set in the OFF position when shipped from the factory.)

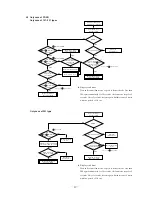

4) Set the control select switch to match the previously set settings on the previous board.

If the previously set settings were set with jumper wires, the control select switch should be set in the ON position if there

was a jumper wire and in the OFF position if there wasn’t a jumper wire.

5) Connect the faston terminals and connectors to the control board.

When connecting the wires to the faston terminals, connect each wire to the terminal printed with the same color on the

board.

Note (1) When connecting the faston terminals to the control board, connect them so that there is no deformation of the far end of the circuit board.