-

223

-

'12 • PAC-T-173

Ԟ

Drain pipe (continued)

2. Prepare a joint for connecting VP-20 pipe, adhere and connect the joint to the drain hose

(the end made of rigid PVC), and adhere and connect VP-20 pipe (prepare on site).

̪

As for drain pipe, apply VP-20 made of rigid PVC which is on the market.

٨

When installing drain pipe, use VP-20 for the pipe goes up the closest to the unit, and

VP-25 or higher number product for farther pipes.

٨

Make sure that the adhesive will not get into the supplied drain hose.

It may cause the flexible part broken after the adhesive is dried up and gets rigid.

٨

The flexible drain hose is intended to absorb a small difference at installation of the unit

or drain pipes. Intentional bending, expanding may cause the flexible hose broken and

water leakage.

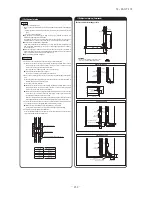

3. Make sure to make descending slope of greater than 1/100 and do not make up-down bend

and/or trap in the midway.

٨

Pay attention not to give stress on the pipe on the indoor unit side, and support and fix the

pipe as close place to the unit as possible when connecting the drain pipe.

٨

Do not set up air vent.

٨

When sharing a drain pipe for more than

one unit, lay the main pipe 100mm

below the drain outlet of the unit. In

addition, select VP-30 or bigger size for

main drain pipe.

Ԟ

Drain pipe (continued)

ԡ

Tap selection on blower unit (when the high peformance filter is used)

ԟ

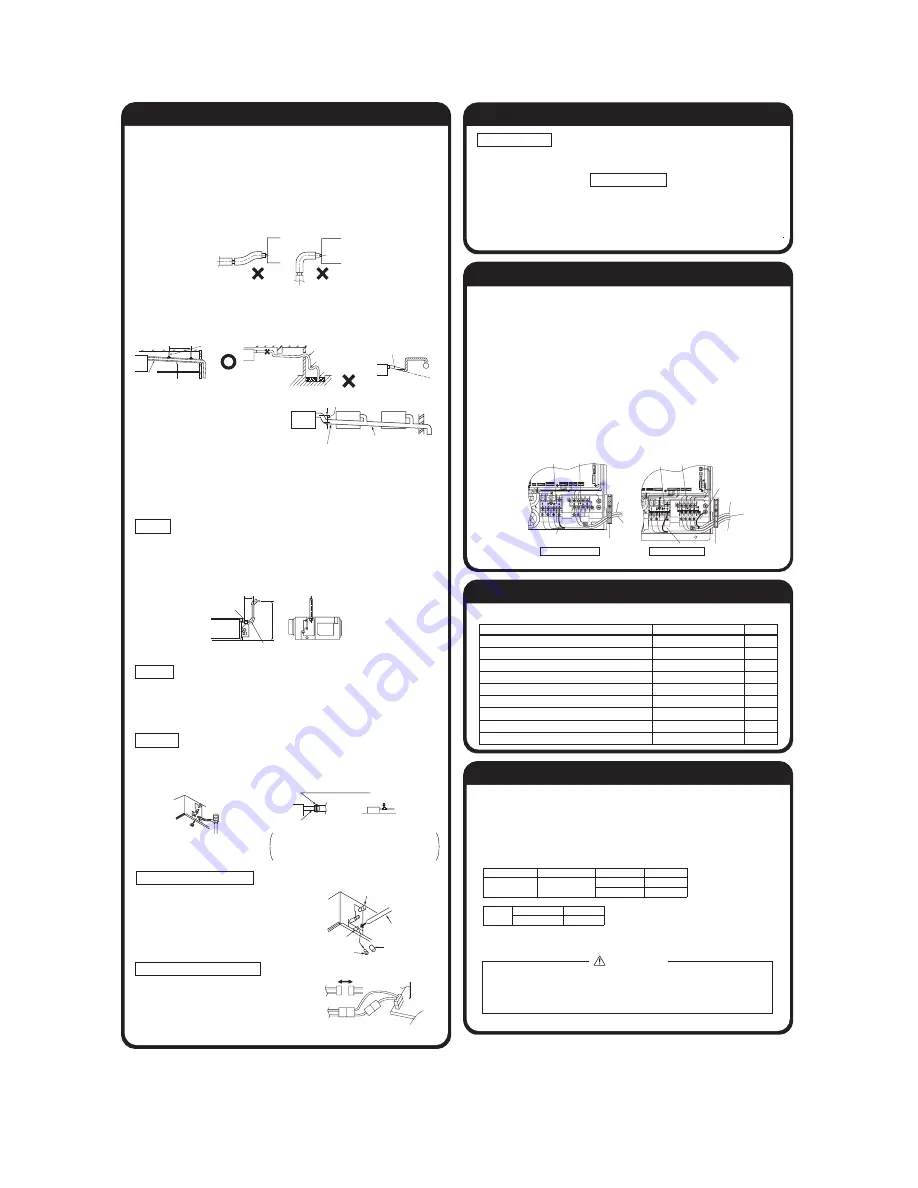

Wiring-out position and wiring connection

Ԡ

Check list after installation

Drain pump operation

٤

In case electrical wiring work finished

ޓ

Drain pump can be operated by remote controller (wired).

ޓ

For the operation method, refer to Operation for drain pump in the installation manual for wiring

work.

٤

In case electrical wiring work not finished

Drain pump will run continuously when the dip switch“SW7-1” on the indoor unit PCB is turned ON, the Connec-

tor CNB is disconnected, and then the power supply (230VAC on the terminal block

Ԙ

and

ԙ

) is turned ON.

Make sure to turn OFF “SW7-1” and reconnect the Connector CNB after the test.

٨

Electrical installation work must be performed according to the installation manual by an

electrical installation service provider qualified by a power provider of the country, and be

executed according to the technical standards and other regulations applicable to electrical

installation in the country.

Be sure to use an exclusive circuit.

٨

Use specified cord, fasten the wiring to the terminal securely, and hold the cord securely in

order not to apply unexpected stress on the terminal.

٨

Do not put both power source line and signal line on the same route. It may cause miscommu-

nication and malfunction.

٨

Be sure to do D type earth work.

٨

For the details of electrical wiring work, see attached instruction manual for electrical wiring

work.

1. Remove a lid of the control box (2 screws).

2. Hold each wiring inside the unit and fasten them to terminal block securely.

3. Fix the wiring with clamps.

4. Install the removed parts back to original place.

The fan tap’s factory setting is “Standard.” If you want to change it to the high static-pressure setting,

you can avail yourself of the following two methods. Use one of the two methods to set the fan tap.

Make sure to perform the functional setting with remote controller.

Select [I/U FUNCTION] in the functional setting mode, and change the function number [02]

[FAN SPEED SET].

For operation method, refer to the user’s manual of the remote controller.

P.C. board

Fuse

For drain motor

connector CNR (blue)

Function number A Functional content B Setting content C Default setting

02

Fan Speed Set

Standard

٤

High Speed 1

Static

Pressure

Standard Tap

60

High Speed 1 Tap

130

UNIT: Pa

Insert water supply hose

for 50mm to

supply water.

(Insert hose facing

toward bottom.)

Attached drain hose clamp

Drain

piping

Main

unit

Drain situation can be checked with transparent socket.

If the electrical work has not been completed, connect a convex

joint in the drain pipe connection to provide a water inlet.

Then, check if water leaks from the piping system and that

drain flows through the drain pipe normally.

Pour water into a convex joint

Remove grommet

Make sure to Install

it back after test.

Connecting port of top drain pipe

Insulating material

Rubber stopper (to be removed)

Connecting port of bottom drain pipes

Standard hard polyvinyl

chloride pipes

(

)

٨

Check the following items after all installation work completed.

Check if

Expected trouble

Check

The indoor and outdoor units are fixed securely?

Falling, vibration, noise

Inspection for leakage is done?

Insufficient capacity

Insulation work is properly done?

Water leakage

Water is drained properly?

Water leakage

Supply voltage is same as mentioned in the model name plate? PCB burnt out, not working at all

There is mis-wiring or mis-connection of piping?

PCB burnt out, not working at all

Earth wiring is connected properly?

Electric shock

Cable size comply with specified size?

PCB burnt out, not working at all

Any obstacle blocks airflow on air inlet and outlet?

Insufficient capacity

Descending slope greater than 1/100

As wide as possible

(about100mm)

Insulation material

Supporting metal

Descending slope greater than 1/100

Air vent

No bump

No trap

Not touching the water

Trapped air will

generate noises.

VP-30 or bigger

1.5m~2m

Single unit wiring connection

Inner/outer

connecting line

Remote

controller line

Power source side

terminal block

Signal side

terminal block

Multi unit wiring connection

Superlynk line

(Shielded cord)

Earth

(Shielded cord)

Indoor power source line

Clamp for wiring at site

Clamp for wiring at site

Signal side

terminal block

Power source side

terminal block

Remote

controller line

Earth

Earth

CNS

CNV

CNT2

CNN

CNN

CNH

CNH

CNZ

CNA

CND

CNK2

CNR2

CNS

CNV

CNT2

CNN

CNH

CNZ

CNA

CND

C

NK2

C

NK1

CAUTION

If the external static pressure is 60Pa or less, do not set the fan speed to High speed 1.

If High speed 1 setting is done, air outlet speed from indoor unit will increase and

waterdrop may be blown out and wet the ceiling or the furniture.

290~325mm

Drain hose

600

Maximum local

drain up dimension

Joint for VP20 (local procurement)

Right overhead

4. Insulate the drain pipe.

٨

Be sure to insulate the drain socket and rigid PVC pipe installed indoors otherwise it may

cause dew condensation and water leakage.

̪

After drainage test implementation, cover the drain socket part with pipe cover (small size), then

use the pipe cover (big size) to cover the pipe cover (small size), clamps and part of the drain

hose, and fix and wrap it with tapes to wrap and make joint part gapless.

Drain up

٨

The position for drain pipe outlet can be raised up to 600mm above the ceiling. Use elbows for

installation to avoid obstacles inside ceiling. If the horizontal drain pipe is too long before vertical pipe,

the backflow of water will increase when the unit is stopped, and it may cause overflow of water from the

drain pan on the indoor unit. In order to avoid overflow, keep the horizontal pipe length and offset of the

pipe within the limit shown in the figure below.

Otherwise, the construction point makes it same as drain pipe construction.

Drain test

1. Conduct a drain test after completion of the electrical work.

2. During the trail, make sure that drain flows properly through the piping and that no water

leaks from connections.

3. In case of a new building, conduct the test before it is furnished with the ceiling.

4. Be sure to conduct this test even when the unit is installed in the heating season.

Procedures

1. Supply about 1000 cc of water to the unit through the air outlet by using a feed water pump.

2. Check the drain while cooling operation.

Outline of bottom drain piping work

٨

If the bottom drain piping can be done with a

descending gradient (1/50-1/100), it is possible to

connect the pipes as shown in the drawing below.

Uncoupling the drain motor connector

٨

Uncouple the connector CNR for the drain motor

as illustrated in the drawing on the right.

Note: If the unit is run with the connector coupled,

drain water will be discharged from the upper drain

pipe joint, causing a water leak.

Summary of Contents for FDC Series

Page 95: ... 94 12 PAC T 173 Models FDT100VF 125VF 140VF H H H H H C B A F G D G PJF000Z285 ...

Page 98: ... 97 12 PAC T 173 Models FDEN60VF 71VF C 2 C 1 A B A B D C 1 C 2 C 1 C 2 E G F B PFA003Z817 ...

Page 113: ... 112 12 PAC T 173 b Wireless remote controller RCN E1R 60 17 150 Unit mm ...

Page 278: ... 277 12 PAC T 173 ー K ...

Page 346: ... 345 12 PAC T 173 Power PCB 1BSU OVNCFS 4GRNCEG VJG 2 ...

Page 518: ... 517 12 PAC T 173 3 5 SUPER LINK E BOARD SC ADNA E F SL2NA E and SL3N AE BE to control ...

Page 519: ... 518 12 PAC T 173 ...