-

225

-

'12 • PAC-T-173

A

28

B

C

Ԛ

Preparation before installation

ԙ

Selection of installation location for the indoor unit

Ԙ

Select the suitable areas to install the unit under approval of the user.

ޓ

Areas where the indoor unit can deliver hot and cold wind sufficiently. Suggest to the user to use

a circulator if the ceiling height is over 3m to avoid warm air being accumulated on the ceiling.

Areas where there is enough space to install and service.

Areas where it can be drained properly. Areas where drain pipe descending slope can be

taken.

Areas where there is no obstruction of airflow on both air return grille and air supply port.

Areas where fire alarm will not be accidentally activated by the air conditioner.

Areas where the supply air does not short-circuit.

Areas where it is not influenced by draft air.

Areas not exposed to direct sunlight.

Areas where dew point is lower than around 28°C and relative humidity is lower than 80%.

This indoor unit is tested under the condition of JIS (Japan Industrial Standard) high humidity

condition and confirmed there is no problem. However, there is some risk of condensation

drop if the air conditioner is operated under the severer condition than mentioned above.

If there is a possibility to use it under such a condition, attach additional insulation of 10 to

20mm thick for entire surface of indoor unit, refrigeration pipe and drain pipe.

Areas where TV and radio stays away more than 1m. (It could cause jamming and noise.)

Areas where any items which will be damaged by getting wet are not placed such as food,

table wares, server, or medical equipment under the unit.

Areas where there is no influence by the heat which cookware generates.

Areas where not exposed to oil mist, powder and/or steam directly such as above fryer.

Areas where lighting device such as fluorescent light or incandescent light doesn’t affect

the operation.

(A beam from lighting device sometimes affects the infrared receiver for the wireless remote

controller and the air conditioner might not work properly.)

ԙ

Check if the place where the air conditioner is installed can hold the weight of the unit. If it is

not able to hold, reinforce the structure with boards and beams strong enough to hold it. If the

strength is not enough, it could cause injury due to unit falling.

Space for installation and service

٨

Make installation altitude over 2.5m.

(Indoor Unit)

Select either of two cases to keep space for installation and services.

Notes (a) There must not be obstacle to draw out fan motor. ( marked area)

(b) Install refrigerant pipe, drain pipe, and wiring so as not to cross marked area.

٨

If suspension bolt becomes longer, do reinforcement of earthquake resistant.

ޓ٤

For grid ceiling

ޓޓ

When the suspension bolt length is over 500mm, or the gap between the ceiling and roof is

over 700mm, apply earthquake resistant brace to the bolt.

ޓ٤

In case the unit is hanged directly from the slab and is installed on the ceiling plane which

has enough strength.

ޓޓ

When suspension bolt length is over 1000mm, apply the earthquake resistant brace to the bolt.

٨

Prepare four (4) sets of suspension bolt, nut and spring washer (M10) on site.

٤

This model is middle static ducted type air conditioning unit. Therefore, do not use this model for direct

blow type air conditioning unit.

Suspension Bolt Location

٤

Adhere to the

measurements given

below for the length of

the suspension bolts.

Suspension

bolt (M10)

Return duct

Air supply duct

Unit

Under

60 mm

UNIT: mm

Multi type

Single type

A

B

C

22-56

50

786

472

135

71, 90

60, 71

986

472

135

112-160

100-140

1404

530

180

Installation

[Hanging]

Hang the unit up.

Adjustment for horizontality

٤

Either use a level vial, or adjust the level according to the method below.

٨

Adjust so the bottom side of the unit will be leveled with the water surface as

illustrated below.

٤

If the unit is not leveled, it may cause malfunctions or inoperation of the float switch.

Pipe side

Pour water

Water

surface

0~5mm

Vinyl hose

Let the pipe side be slightly sloped.

ԛ

Installation of indoor unit

M10 nut

Suspension bolt

Spring washer for M10

Unit

Washer for M10

If the measurements between

the unit and the ceiling hole do

not match upon installation, it

may be adjusted with the long

holed installation tool.

Multi type

Single type

112-160

100-140

Pipe locations UNIT: mm

Multi type

Single type

22-90

50-71

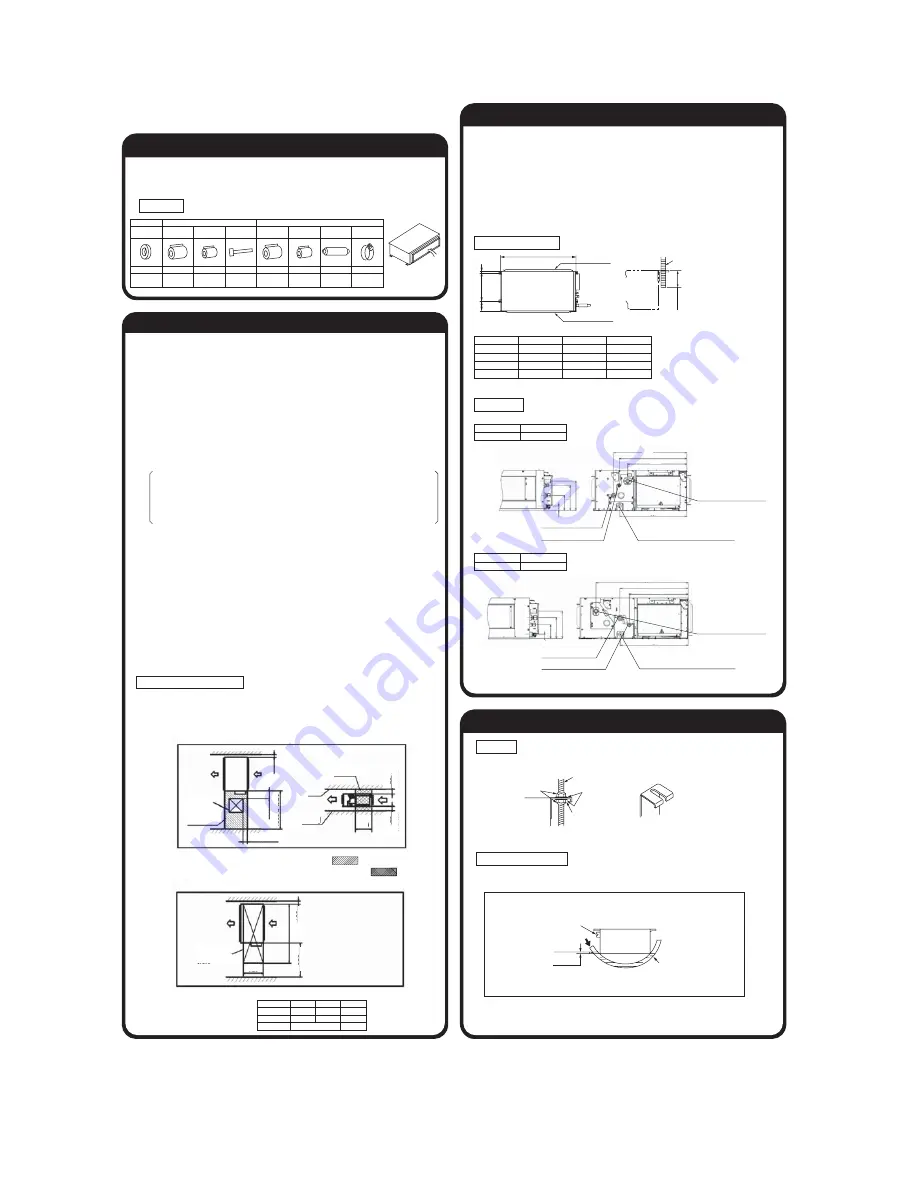

Ԙ

Before installation

٨

Install correctly according to the installation manual.

٨

Confirm the following points:

ޓ٤

Unit type/Power supply specification

٤

Pipes/Wires/Small parts

٤

Accessory items

Accessory item

Accessory parts are stored

inside this suction side.

For refrigerant pipe

For drain pipe

Pipe cover (big) Pipe cover (small)

Pipe cover (big) Pipe cover (small)

Drain hose

Hose clamp

Strap

1

1

4

1

1

1

1

For heat insulation

of gas pipe

For heat insulation

of liquid tube

For pipe

cover fixing

For hanging

Flat washer (M10)

8

For unit

hanging

For drain hose

mounting

For heat insulation

of drain socket

For heat insulation

of drain socket

For drain pipe

connecting

Single type

Multi type

A

B

(Size of inspection hole)

50

22-56

1100

60-71

71-90

1300

100-140

112-160

1720

725

(For natural drainage)

drain pipe connection VP20 (PVC pipe)

drain pipe connection VP20

(PVC pipe)

510

635

468

405

467

187

145

95

29

471

413

203

174

104

29

467

Refrigerant liquid pipe

Refrigerant gas pipe

(For natural drainage)

drain pipe connection VP20 (PVC pipe)

drain pipe connection VP20

(PVC pipe)

Refrigerant gas pipe

Refrigerant liquid pipe

(Case 2) From bottom of unit

(Case 1) From side of unit

600

or more

100

or more

100

or more

20

or more

20

or more

A

B

Inspection

hole

Note (a)

Note (b)

100-200

370

150-

200

Ceiling

Slab

Inspection

hole

(450x450)

1000 or more

UNIT: mm

UNIT: mm

UNIT: mm

620

Summary of Contents for FDC Series

Page 95: ... 94 12 PAC T 173 Models FDT100VF 125VF 140VF H H H H H C B A F G D G PJF000Z285 ...

Page 98: ... 97 12 PAC T 173 Models FDEN60VF 71VF C 2 C 1 A B A B D C 1 C 2 C 1 C 2 E G F B PFA003Z817 ...

Page 113: ... 112 12 PAC T 173 b Wireless remote controller RCN E1R 60 17 150 Unit mm ...

Page 278: ... 277 12 PAC T 173 ー K ...

Page 346: ... 345 12 PAC T 173 Power PCB 1BSU OVNCFS 4GRNCEG VJG 2 ...

Page 518: ... 517 12 PAC T 173 3 5 SUPER LINK E BOARD SC ADNA E F SL2NA E and SL3N AE BE to control ...

Page 519: ... 518 12 PAC T 173 ...