-

228

-

'12 • PAC-T-173

Ԡ

External static pressure setting (continued)

Indoor unit fan will run automatically and recognize E.S.P. by itself.

The operation for automatic E.S.P recognition will last about 6 minutes, and it will be stopped

after recognition is completed.

Caution

· Be sure to execute AUTOMATIC SETTING by remote controller AFTER ducting work is completed.

When duct specification is changed after AUTOMATIC SETTING, be sure to execute AUTOMATIC

SETTING again after power resetting and turning on again.

· Be sure to execute AUTOMATIC SETTING before trial cooling operation.

(See ELECTRICAL WIRING WORK INSTRUCTION about trial cooling operation)

· Before AUTOMATIC SETTING, be sure to check that return air filter in duct is installed and

damper is opened.

Wrong procedure causes excessive air flow or water drop blown out.

Notice

· During operation for automatic recognition (the Auto Operation), fan rotates with certain speeds

regardless of set fan speed by remote controller.

· When duct is set with low static pressure (around 10-50Pa), even if indoor unit operate with

higher air flow volume than rated one, but it is not abnormal.

· When you changed operation mode or stop operation with ON/OFF button during Auto Opera-

tion, the Auto operation will be canceled.

· In such case, be sure to execute AUTOMATIC SETTING again according to above procedure.

ԡ

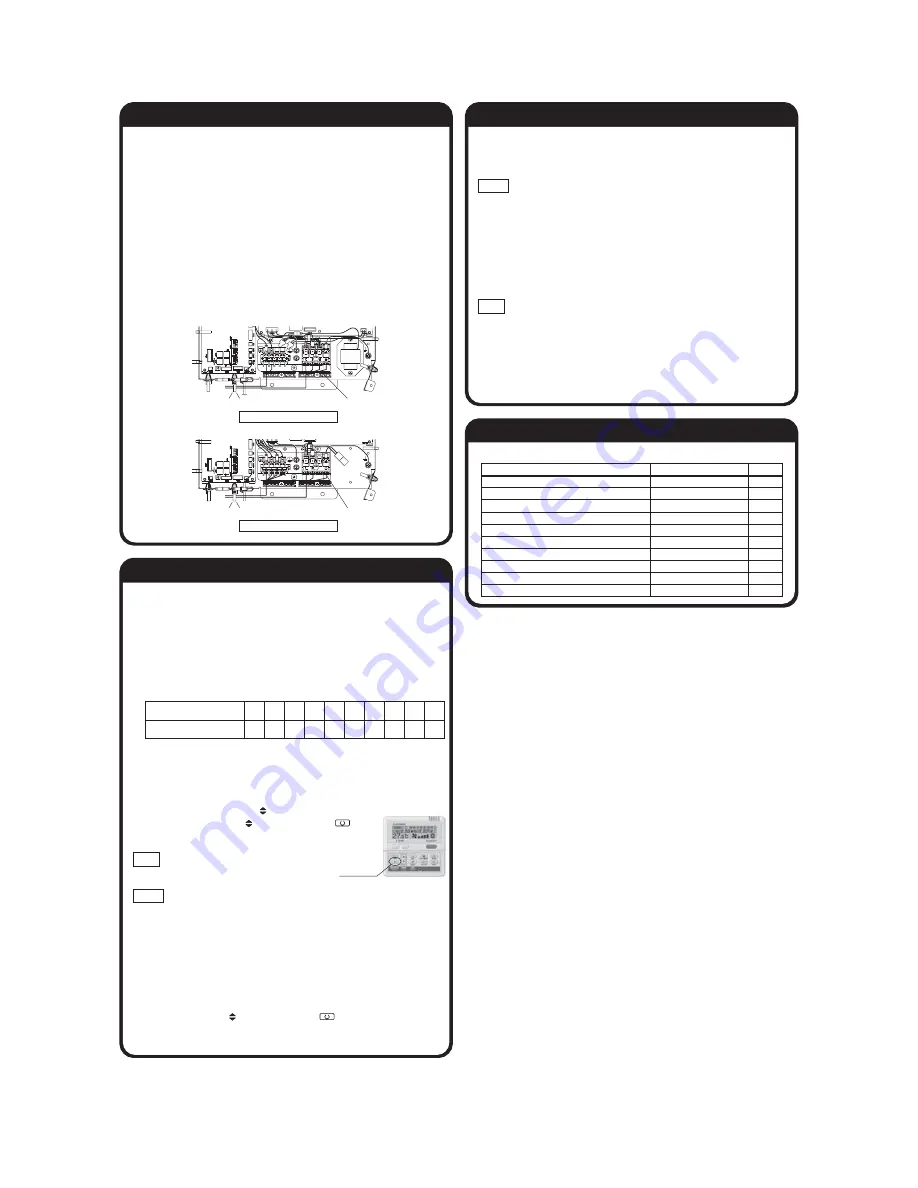

Check list after installation

٨

Check the following items after all installation work completed.

PJG012D001

Check

Check if

The indoor and outdoor units are fixed securely ?

Inspection for leakage is done ?

Insulation work is properly done ?

Water is drained properly ?

Supply voltage is same as mentioned in the model name plate ?

No mis-wiring or mis-connection of piping ?

Earth wiring is connected properly ?

Cable size comply with specified size ?

Any obstacle blocks airflow on air inlet and outlet ?

Is setting of E.S.P finished ?

Expected trouble

Falling, vibration, noise

Insufficient capacity

Water leakage

Water leakage

PCB burnt out, not working at all

PCB burnt out, not working at all

Electric shock

PCB burnt out, not working at all

Insufficient capacity

Excessive air flow, water drop blow out

Ԡ

External static pressure setting

You can set External Static Pressure (E.S.P.) by either method of MANUAL SETTING or AUTO-

MATIC SETTING by remote controller.

Indoor unit will control fan-speed to keep rated air flow volume at each fan speed setting (Lo-Uhi)

1. MANUAL SETTING

You can set required E.S.P. by wired remote controller that calculated with the set air flow

rate and pressure loss of the duct connected.

Select No.1-10 (10Pa-100Pa) from following table according to calculation result.

Refer to technical manual for details of air flow characteristic.

̪

When you set No.11-19 by remote controller, unit will control fan-speed with setting of

No.10 Factory default is at No.5.

٨

How to set E.S.P by wired remote controller

䡾

Push "

ٟ

" marked button(E.S.P button).

䡿

Select indoor unit No. by using button.

䢀

Select setting No. by using button and set E.S.P. by button.

See detailed procedure in technical manual.

Notice

You can NOT set E.S.P by wireless remote controller.

Caution

Be sure to set E.S.P. according to actual duct connected.

Wrong settings causes excessive air flow volume or water drop blown out.

2. AUTOMATIC SETTING

Indoor unit will recognize E.S.P. by itself automatically and select appropriate fan speed No.1-10.

٨

How to start automatic setting

䡾

,

䡿

Same setting as MANUAL SETTING.

䢀

Select [AUT] by using button and press button .

䡿

After setting E.S.P. at "AUT", operate unit in FAN mode with certain fan speed (Lo-Uhi).

Setting No.

External Static Pressure (Pa)

1

10

2

20

3

30

4

40

5

50

6

60

7

70

8

80

9

90

10

100

ԟ

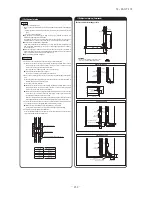

Wiring-out position and wiring connection

٨

Electrical installation work must be performed according to the installation manual by an

electrical installation service provider qualified by a power provider of the country, and be

executed according to the technical standards and other regulations applicable to electrical

installation in the country.

Be sure to use an exclusive circuit.

٨

Use specified cord, fasten the wiring to the terminal securely, and hold the cord securely in

order not to apply unexpected stress on the terminal.

٨

Do not put both power source line and signal line on the same route. It may cause miscom-

munication and malfunction.

٨

For the details of electrical wiring work, see attached instruction manual for electrical wiring

work.

1. Remove a lid of the control box (2 screws).

2. Hold each wiring inside the unit and fasten them to terminal block securely.

3. Fix the wiring with clamps.

4. Install the removed parts back to original place.

Power source line

Signal line

Earth

Earth

Single unit wiring connection

Multi unit wiring connection

Power source line

Signal line

E.S.P. button

Summary of Contents for FDC Series

Page 95: ... 94 12 PAC T 173 Models FDT100VF 125VF 140VF H H H H H C B A F G D G PJF000Z285 ...

Page 98: ... 97 12 PAC T 173 Models FDEN60VF 71VF C 2 C 1 A B A B D C 1 C 2 C 1 C 2 E G F B PFA003Z817 ...

Page 113: ... 112 12 PAC T 173 b Wireless remote controller RCN E1R 60 17 150 Unit mm ...

Page 278: ... 277 12 PAC T 173 ー K ...

Page 346: ... 345 12 PAC T 173 Power PCB 1BSU OVNCFS 4GRNCEG VJG 2 ...

Page 518: ... 517 12 PAC T 173 3 5 SUPER LINK E BOARD SC ADNA E F SL2NA E and SL3N AE BE to control ...

Page 519: ... 518 12 PAC T 173 ...