-

235

-

'12 • PAC-T-173

Installation board

5 cm minimum

from the wall

10 cm minimum

from the wall

7.0 cm minimum from the ceiling

Wireless remote control

Remote control holder

Wood screws

Sleeve

(sold separately)

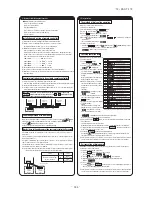

Necessary tools for the installation work

1

2

3

4

5

6

7

8

9

10

11

12

13

①

②

③

④

⑤

⑥

⑦

⑧

⑨

1

1

1

4

2

2

2

2

1

1

1

1

1

1

1

Q'ty

Q'ty

Standard accessories (Installation kit)

Accessories for indoor unit

Installation board

(Attached to the rear of the indoor unit)

Wireless remote control

Remote control holder

Battery

[R03(AAA,Micro) 1.5V]

Air-cleaning filters

Filter holders

(Attached to the front panel of indoor unit)

Insulation (#486 50 x 100 t3)

Tapping screws

(for installation board 4dia. by 25mm)

Wood screw

(for remote control switch holder 3.5(mm). by 16mm)

Option parts

Sealing plate

Sleeve

Inclination plate

Putty

Drain hose (extention hose)

Piping cover

(for insulation of connection piping)

Plus headed driver

Knife

Saw

Tape measure

Hammer

Spanner wrench

Torque wrench

Hole core drill (65mm in diameter)

Wrench key (Hexagon) [4m/m]

Flaring tool set

Gas leak detector

Pipe bender

Gauge for projection adjustment

Used when flare is made by using

conventional flare tool

()

()

()

14.0 ~ 61.0N·m

(1.4 ~ 6.1kgf·m)

(

Designed specifically

for R410A

Designed specifically

for R410A

)

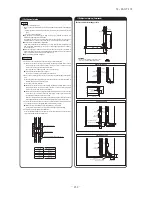

Piping in the left direction

Piping in the right rear direction

Piping in the left rear direction

Piping in the right direction

INSTALLATION SPACE (INDOOR UNIT)

(FRONT VIEW)

50

Space for

service

Space for

service

120

220

650

450

220

100

120

35

35

58

54

520.8

491.1

559.1

49

222.5

48

70Space for service

15Space for service

7.7

295.7

5.6

48

Indoor unit

Installation board

Drain hose (ø16)

Piping for Gas

Piping for Liquid

Piping hole (ø65)

Piping hole (ø65)

Standard hole

Piping is possible in the rear, left,

left rear, left downward, right or

downward direction.

Right

Rear

Downward

Left rear

Left downward

Left

BEFORE INST

ALLA

TION

c

Before installation check that the power supply matches the air conditioner.

SELECTION OF INSTALLATION LOCATION

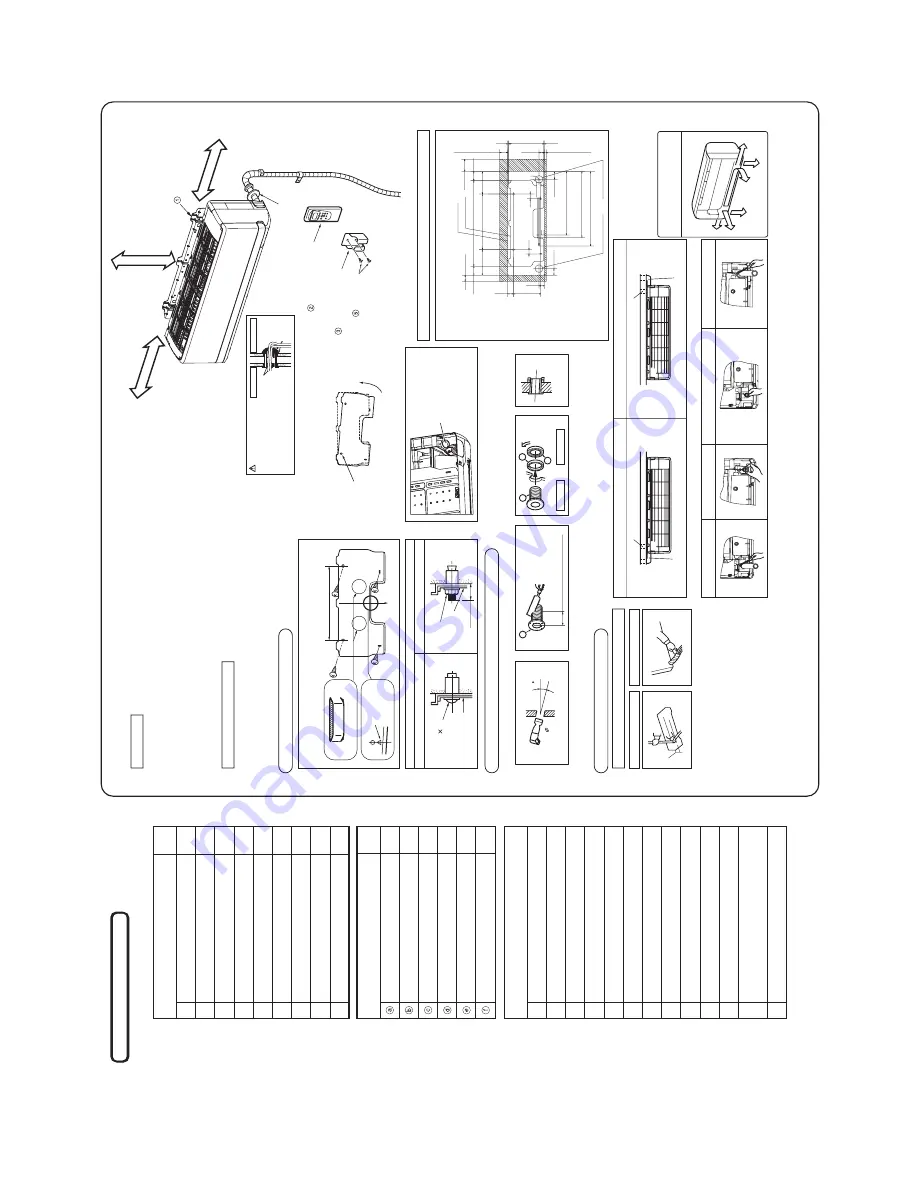

INSTALLATION OF INDOOR UNIT

Indoor unit

Relation between setting plate and indoor unit

Installing the support of piping

(Install at location that meets the following conditions, after getting approval from the customer)

c

Where there is no obstructions to the air flow and where the cooled and heated air can be evenly distributed.

c

A solid place where the unit or the wall will not vibrate.

c

A place where there will be enough space for servicing. (Where space mentioned below can be secured)

c

Where wiring and the piping work will be easy to conduct.

c

The place where receiving part is not exposed to the direct rays of the sun or the strong rays of the street lighting.

c

A place where it can be easily drained.

c

A place separated at least 1m away from the television or the radio. (To prevent interference to images and sounds.)

c

Places where this unit is not affected by the high frequency equipment or electric equipment.

c

Avoid installing this unit in place where there is much oil mist.

c

Places where there is no electric equipment or household under the installing unit.

Wireless remote control

In case of piping in the right rear direction

c

A place where the air conditioner can be received the signal surely during operating the wireless remote control.

c

Places where there is no affected by the TV and radio etc.

c

Do not place where exposed to direct sunlight or near heat devices such as a stove.

c

Hold the bottom of the

piping and fix direction

before stretching it and

shaping it.

Sufficient care must be taken not to damage

the panel when connecting pipes.

c

Drill a hole with whole core drill.

c

In case of rear piping draw out, cut off the lower

and the right side portions of the sleeve collar.

c

Tape only the portion

that goes through the

wall.

c

Always tape the wiring

with the piping.

[Top view]

When drilling the wall that contains a metal lath, wire lath or metal plate, be sure to use pipe hole sleeve sold separately.

z

Matters of special notice when piping from left or central/rear of tha unit.

[Drain hose changing procedures]

c

Remove the screw and

drain hose, making it

rotate.

c

Remove it with hand or

pilers.

c

Insert the drain cap which was removed

at procedure “2” securely using a

hexagonal wrench etc.

Note: Be careful that If it is not Inserted

securely, water leakage may

occur.

c

Insert the drain hose securely,

making rotate. And install the

screw.

Note: Be careful

that If it is not

Inserted securely, water

leakage may occur.

Left-hand-side piping

Right-hand-side piping

1. Remove the drain hose.

2. Remove the drain cap.

3. Insert the drain cap.

4. Connect the drain hose.

Installation of Installation board

Drilling of holes and fixture of sleeve (Option parts)

Look for the inside wall structures (Intersediats support or pillar and finally

install the unit after level surface has been checked.)

450

Level position (2 locations)

Mating mark for

level surface

Fixing on concrete wall

Use of nut anchor

Use of bolt anchor

Shaping of pipings

Taping of the exterior

Pipings

Drain hose

Top

Indoor side

Outdoor side

Nut

(M6)

Mounting

board

Mounting

board

Max.10

Thicknese of the wall + 1.5cm

5

65

Indoor side

Outdoor side

Installed state

Turn to

tighten

b

b

c

a

Bolt

(M6 12)

Piping for Liquid (20 to 60 type) : ø6.35

Piping for Gas (20 to 35 type) : ø9.52

(50 to 60 type) : ø12.7

c

Adjustment of the installation board in the horizontal

direction is to be conducted with four screws in a temporary

tightened state.

c

Adjust so the board will be level by turning the board with

the standard hole as the center.

CA

UTION

putty

putty

Indoor side

Outdoor side

Completely seal the hole on

the

w

all with putty

. Otherwise

,

fur

niture

, or other

, ma

y be

w

e

tted

b

y

leak

ed

w

ater or

de

wing.

Nothing is connected to this

hole on the back of indoor

unit.

Summary of Contents for FDC Series

Page 95: ... 94 12 PAC T 173 Models FDT100VF 125VF 140VF H H H H H C B A F G D G PJF000Z285 ...

Page 98: ... 97 12 PAC T 173 Models FDEN60VF 71VF C 2 C 1 A B A B D C 1 C 2 C 1 C 2 E G F B PFA003Z817 ...

Page 113: ... 112 12 PAC T 173 b Wireless remote controller RCN E1R 60 17 150 Unit mm ...

Page 278: ... 277 12 PAC T 173 ー K ...

Page 346: ... 345 12 PAC T 173 Power PCB 1BSU OVNCFS 4GRNCEG VJG 2 ...

Page 518: ... 517 12 PAC T 173 3 5 SUPER LINK E BOARD SC ADNA E F SL2NA E and SL3N AE BE to control ...

Page 519: ... 518 12 PAC T 173 ...