-

240

-

'12 • PAC-T-173

Drain pump operation from remote control unit is possible. Operate a remote control unit by

following the steps described below.

1. To start a forced drain pump operation.

Ԙ

Press the TEST button for three seconds or longer.

The display will change “ ”

ԙ

Press the button once and cause “ ” to be displayed.

Ԛ

When the (SET) button is pressed, a drain pump operation will start.

Display: “ ”

2. To cancel a drain pump operation.

Ԙ

If either (SET) or button is pressed, a forced drain pump operation will

stop. The air conditioning system will become OFF.

٧

If two (2) remote controllers are connected to one (1) inside unit, only the master controller is available

for trial operation and confirmation of operation data. (The slave remote controller is not available.)

Operation data can be checked with remote

control unit operation.

1. Press the button.

The display change “ ”

2. Press the (SET) button while

“ ” is displayed.

When only one indoor unit is connected

to remote controller, “ ” is

displayed (blinking indication during data

loading).

Next, operation data of the indoor unit

will be displayed. Skip to step 7.

4. When plural indoor units is connected,

the smallest address number of indoor

unit among all connected indoor unit is

displayed.

[Example]:

“ ” (blinking 1 seconds)

“ ” blinking.

5. Select the indoor unit number you would

like to have data displayed with the

button.

6. Determine the indoor unit number with the

(SET) button.

(The indoor unit number changes from

blinking indication to continuous indication)

“ ” (The address of selected

indoor unit is blinking for 2 seconds.)

“ ” (A blinking indication appears while data loaded.)

Next, the operation data of the indoor unit is indicated.

7. Upon operation of the button, the current operation data is displayed in order from

data number 01.

The items displayed are in the above table.

̪

Depending on models, the items that do not have corresponding data are not displayed.

8. To display the data of a different indoor unit, press the button, which allows you to

go back to the indoor unit selection screen.

9. Pressing the button will stop displaying data.

Pressing the (RESET) button during remote control unit operation will undo your last

operation and allow you to go back to the previous screen.

٧

If two (2) remote controllers are connected to one (1) inside unit, only the master controller is available

for trial operation and confirmation of operation data. (The slave remote controller is not available.)

After a unit is energized, it is possible to display an indoor unit address by pressing

button on the remote control unit. Press the or button to make sure

that all indoor units connected are displayed in order.

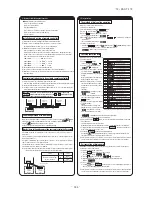

Control plural indoor units by a single remote controller.

Confirming method of indoor units

Master/ slave setting when more than one remote control unit are used

Ԙ

A remote controller can control plural indoor units (Up to 16).

ԙ

Remote Control, Wiring and functions

Wired remote controller: SW1

Wireless kit: SW1-2

Switch

setting

contents

Master

remote controller

Slave

remote controller

M

S

Indoor Unit (1)

Address “0”

Indoor Unit (2)

Address“1”

Indoor Unit (16)

Address“F”

Remote controller

Remote controller line (no polarity)

Remote

controller

“Master”

Remote

controller

“Slave”

Indoor Unit

Remote controller line

(no polarity)

Installation and wiring of remote controller

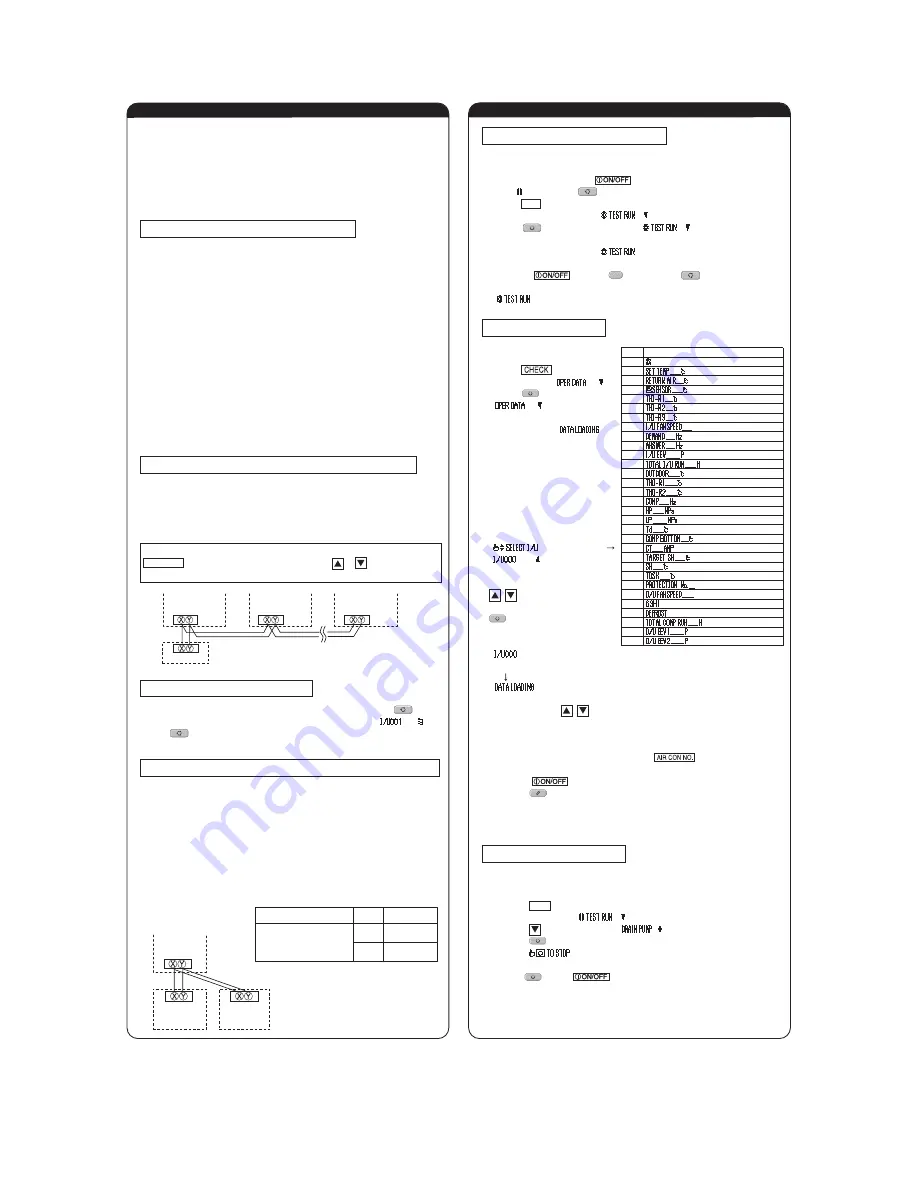

The method of trial cooling operation

Checking operation data

Ԛ

Trial operation

Trail operation of drain pump

Number

01

02

03

04

05

06

07

08

09

10

11

12

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

Data Item

(Ope ration Mode)

(Set Temperature)

(Return Air Temperature)

(Remote Controller ThermistorTemperature)

(Indoor Unit Heat Exchanger Thermistor / U Bend)

(Indoor Unit Heat Exchanger Thermistor /Capillary)

(Indoor Unit Heat Exchanger Thermistor /Gas Header)

(Indoor Unit Fan Speed)

(Frequency Requirements)

(Response Frequency)

(Pulse of Indoor Unit Expansion Value)

(Total Running Hours of The Indoor Unit)

(Outdoor Air Temperature)

(Outdoor Unit Heat Exchanger Thermistor)

(Outdoor Unit Heat Exchanger Thermistor)

(Compressor Frequency)

(High Pressure)

(Low Pressure)

(Discharge Pipe Temperature)

(Comp Bottom Temperature)

(Current)

(Target Super Heat)

(Super Heat)

(Discharge Pipe Super Heat)

(Protection State No. of The Compressor)

(Outdoor Unit Fan Speed)

(63H1 On/Off)

(Defrost Control On/Off)

(Total Running Hours of The Compressor)

(Pulse of The Outdoor Unit Expansion Valve EEVC)

(Pulse of The Outdoor Unit Expansion Valve EEVH)

ԛ

Avoid using multi-core cables to prevent malfunction.

Ԝ

Keep remote controller line away from earth (frame or any metal of building).

ԝ

Make sure to connect remote controller line to the remote controller and terminal block of indoor

unit. (No polarity)

In above setting, all plural indoor units will operate under same mode and temperature setting.

ԙ

Connect all indoor units with 2 core remote controller line.

Ԛ

Set unique remote control communication address from "0" to "F" to each inside unit by the

rotary switch SW2 on the indoor unit's PCB.

When indoor unit address number is displayed on remote controller, pushing the (MODE)

button to make the indoor unit with that number blow air (Display example:" ")

Push the (MODE) button again to stop the operation.

However, this operation is invalid on the air-conditioning running.

A maximum of two remote control units can be connected to one indoor unit (or one group of

indoor units.)

The air conditioner operation follows the last operation of the remote controller regardless of the

master/slave setting of it.

Acceptable combination is "two (2) wired remote controllers", "one (1) wired remote controller

and one (1) wireless kit" or "two (2) wireless kits".

Set SW1 (wired remote controller) or SW1-2 (wireless kit) to "Slave" for the slave remote control

unit. It was factory set to "Master" for shipment.

Note:The setting "Remote control unit sensor enabled" is only selectable with the master remote

control unit in the position where you want to check room temperature.

٨

DO NOT install it on the following places

Ԙ

Places exposed to direct sunlight

ԙ

Places near heat devices

Ԛ

High humidity places

ԛ

Hot surface or cold surface enough to generate condensation

Ԝ

Places exposed to oil mist or steam directly.

ԝ

Uneven surface

Operate the remote control unit as follows.

1. Starting a cooling test run.

Ԙ

Start the system by pressing the button.

ԙ

Select “ (Cool)” with the (MODE) button.

Ԛ

Press the

TEST

button for 3 seconds or longer.

The screen display will switch to: “ ”

ԛ

When the (SET) button is pressed while “ ” is indicated, a cooling test

run will start.

The screen display will switch to “ ”.

2. Ending a cooling test run.

Pressing the button, the (TEMP) button or (MODE) button will end a

cooling test run. (Cooling test run will end after 30 minutes pass.)

“ ” shown on the screen will go off.

Ԙ

Install remote controller referring to the attached installation manual.

ԙ

Wiring of remote controller should use 0.3mm

2

×

2 core wires or cables.

The insulation thickness is 1mm or more. (on-site configuration)

Ԛ

Maximum prolongation of remote control wiring is 600 m.

If the prolongation is over 100m, change to the size below.

But, wiring in the remote controller case should be under 0.5mm

2

. Change the wire size

outside of the case according to wire connecting. Waterproof treatment is necessary at the

wire connecting section. Be careful about contact failure.

100 - 200m ........................ 0.5mm

2

× 2 cores

Under 300m ....................... 0.75mm

2

× 2 cores

Under 400m ....................... 1.25mm

2

× 2 cores

Under 600m ....................... 2.0mm

2

× 2 cores

̪

Depending on outdoor unit model, there are data not shown.

AIR CON NO.

Summary of Contents for FDC Series

Page 95: ... 94 12 PAC T 173 Models FDT100VF 125VF 140VF H H H H H C B A F G D G PJF000Z285 ...

Page 98: ... 97 12 PAC T 173 Models FDEN60VF 71VF C 2 C 1 A B A B D C 1 C 2 C 1 C 2 E G F B PFA003Z817 ...

Page 113: ... 112 12 PAC T 173 b Wireless remote controller RCN E1R 60 17 150 Unit mm ...

Page 278: ... 277 12 PAC T 173 ー K ...

Page 346: ... 345 12 PAC T 173 Power PCB 1BSU OVNCFS 4GRNCEG VJG 2 ...

Page 518: ... 517 12 PAC T 173 3 5 SUPER LINK E BOARD SC ADNA E F SL2NA E and SL3N AE BE to control ...

Page 519: ... 518 12 PAC T 173 ...