-

242

-

'12 • PAC-T-173

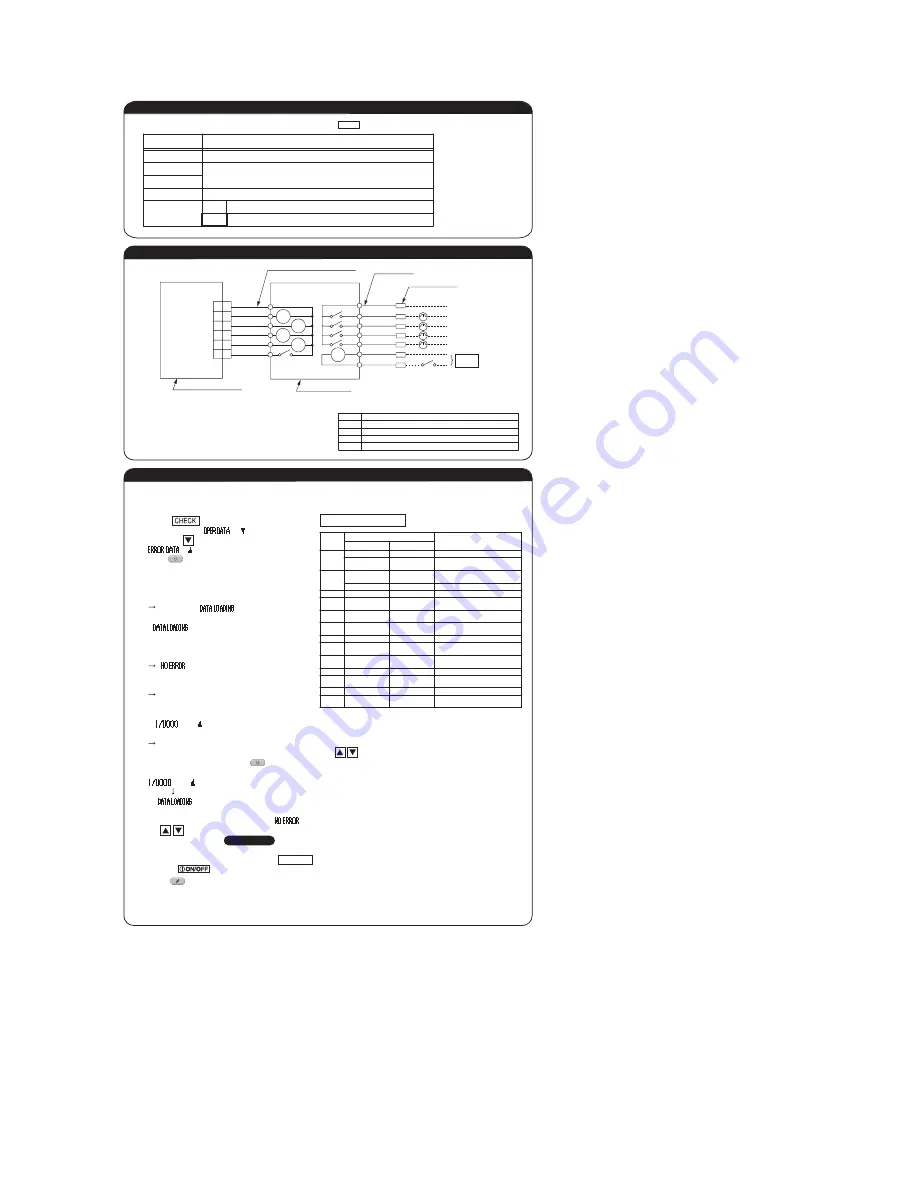

The operation data is saved when the situation of abnormal operation

happen, and the data can be confirmed by remote controller.

[Operating procedure]

1. Press the button.

The display change “ ”

2. Once, press the button, and the display change

“ ”.

3. Press the (SET) button and abnormal operation data mode is

started.

4. When only one indoor unit is connected to remote controller, following

is displayed.

Ԙ

The case that there is history of abnormal operation.

Error code and “ ” is displayed.

[Example]: [E8] (ERROR CODE)

“ ” is displayed (blinking indication during data loading).

Next, the abnormal operation data of the indoor unit will be displayed.

Skip to step 8.

ԙ

The case that there is not history of abnormal operation.

“ ” is displayed for 3 seconds and this mode is closed.

5. When plural indoor units is connected, following is displayed.

Ԙ

The case that there is history of abnormal operation.

Error code and the smallest address number of indoor unit

among all connected indoor unit is displayed.

[Example]: [E8] (ERROR CODE)

“ ” blinking

ԙ

The case that there is not history of abnormal operation.

Only address number is displayed.

6. Select the indoor unit number you would like to have data displayed with the button.

7. Determine the indoor unit number with the (SET) button.

[Example]: [E8] (ERROR CODE)

“ ” (The address of selected indoor unit is blinking for 2 seconds.)

[E8] “ ” (A blinking indication appears while data loaded.)

Next, the abnormal operation data is indicated.

If the indoor unit doing normal operation is selected, “ ” is displayed for 3 seconds and address of indoor unit is displayed.

8. By the button, the abnormal operation data is displayed.

Displayed data item is based on

Ԛ

Trial operation

̪

Depending on models, the items that do not have corresponding data are not displayed.

9. To display the data of a different indoor unit, press the AIR CON No. button, which allows you to go back to the indoor unit slection screen.

10.Pressing the button will stop displaying data.

Pressing the (RESET) button during remote control unit operation will undo your last operation and allow you to go back to the previous screen.

٧

If two (2) remote controllers are connected to one (1) indoor unit, only the master controller is available for trial operation and confirmation of operation

data. (The slave remote controller is not available.)

٨

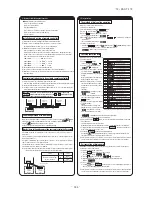

CNT connector (local) vendor model

Connector : Made by molex

ޓ

5264 - 06

Terminals : Made by molex

ޓ

5263T

٨

Function

ԝ

Function of CNT connector of indoor printed circuit board

Ԟ

Troubleshooting

Off

E1

E5

E6

E7

E8

E9

E10

E14

E16

E19

E28

Over E30

Off

Off

Off

Not sure

Blinking twice

Blinking once

Blinking once

Blinking once

Blinking once

Off

Blinking for three times

Blinking once

Blinking once

Off

Off

Continuous blinking

Off

Continuous blinking

Not sure

Continuous blinking

Continuous blinking

Continuous blinking

Continuous blinking

Continuous blinking

Continuous blinking

Continuous blinking

Continuous blinking

Continuous blinking

Continuous blinking

Continuous blinking

Normal

Fault on power, indoor power off or lack

phase

Fault on the transmission between

indoor circuit board and remote control

Indoor computer abnormal

Fault on outdoor-indoor transmission

Indoor heat exchange sensor interrupted or

short-circuit

Indoor air inhaling sensor broken or

short-circuit

The temperature of heat exchange

abnormal

Float SW actions (only with FS)

Excess number of remote controller

connections

The communication fault for master/slave

indoor units

Fan motor abnormal

Configuration fault on running checking

model

Remote controller sensor interrupted

Outdoor unit checking (outdoor circuit board

LED checking)

red (checking)

green (normal)

Content

Display on

remote

controller

LED on indoor circuit board

Output 1

Output 2

Output 3

Output 4

Input 5

Operation output (there is output when unit is in operation.)

Heating output (there is output when operation MODE is HEATING.)

Compressor ON output (there is output when compressor is in operation.)

Inspection output (there is output when unit is stopped by error.)

Remote operation input (Volt-free contact) (Inputted to operate unit)

Error Code of indoor unit

٨

Ԝ

Control mode switching

Indoor units

control box

Do not use the length over 2 meter

CNT

(Blue 6P)

Common

Output 1

Output 2

Output 3

Output 4

Remote start / stop button or timer point

Butt splice

(Application coverage

0.75

㨪

1.25mm

2

)

Remote start/stop kit

0.75 mm

2

Note (1) 0.3 mm

2

×2m

Red

Black

Yellow

Blue

Brown

Orange

White

Black

Yellow

Blue

Brown

Orange

Orange

Switch No.

SW2

SW5-1

SW5-2

SW6-1

㨪

4

SW7

㧙

1

Control Content

Indoor unit address (0-Fh)

Master/Slave Switching (plural /Slave unit Setting)

Model capacity setting

ON

Operation check, Drain motor test run

OFF

Normal operation

Input

power

The control content of indoor units can be switched in following way. ( is the default setting)

+12

PCB (Printed Circuit Board)

×0.2m

XR1

XR1

XR2

XR3

XR4

XR2

XR3

XR4

XR5

1

1

2

2

3

3

4

4

5

5

6

6

Summary of Contents for FDC Series

Page 95: ... 94 12 PAC T 173 Models FDT100VF 125VF 140VF H H H H H C B A F G D G PJF000Z285 ...

Page 98: ... 97 12 PAC T 173 Models FDEN60VF 71VF C 2 C 1 A B A B D C 1 C 2 C 1 C 2 E G F B PFA003Z817 ...

Page 113: ... 112 12 PAC T 173 b Wireless remote controller RCN E1R 60 17 150 Unit mm ...

Page 278: ... 277 12 PAC T 173 ー K ...

Page 346: ... 345 12 PAC T 173 Power PCB 1BSU OVNCFS 4GRNCEG VJG 2 ...

Page 518: ... 517 12 PAC T 173 3 5 SUPER LINK E BOARD SC ADNA E F SL2NA E and SL3N AE BE to control ...

Page 519: ... 518 12 PAC T 173 ...