-

265

-

'12 • PAC-T-173

Accessories for outdoor unit

• Model name and power sour

ce

• Refrigerant piping length

• Piping, wiring and miscellaneous small parts

• Indoor unit installation manual

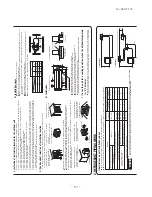

Necessary tools for the installation work

W

rench key (Hexagon) [4m/m]

V

acuum pump

V

acuum pump adapter (Anti-r

everse flow type)

(Designed specifically for R410A)

Gauge manifold (Designed specifically for R410A)

Charge hose (Designed specifically for R410A)

Flaring tool set (Designed specifically for R410A)

Gas leak detector (Designed specifically for R410A)

Gauge for pr

ojection adjustment

(Used when flar

e is made by using conventional flar

e tool)

9

10

11

12

13

14

15

16

Plus headed driver

Knife

Saw

Tape measur

e

Hammer

Spanner wr

ench

To

rque wr

ench [14.0

~

62.0N·m (1.4

~

6.2kgf·m)]

Hole cor

e drill (65mm in diameter)

1

2

3

4

5

6

7

8

Gr

ommet (Heat pump type only)

Drain elbow (Heat pump type only)

Q’

ty

4

1

1

2

Option parts

Sealing plate

Sleeve

Inclination plate

Putty

Drain hose (extension hose)

Piping cover

(for insulation of connection piping)

Q’

ty

1

1

1

1

1

1

Check befor

e installation work

a

b

c

d

e

f

•

Carr

y out the electrical work for ground lead with care.

Do not connect the ground lead to the gas line,

water line,

lightning conductor or telephone line’

s ground lead.

Incorrect grou

nding can cause unit faults such as electric shocks due to short-circuiting.

•

Use the circuit breaker for all pole correct capacity

. Circuit breaker

should be the one that disconnect all poles under o

ver current.

Using the incorrect circuit breaker

, it can cause the unit malfunction and fire.

•

Install isolator or disconnect switch on the power supply wiring in

accordance with the local codes and regulations.

The isolator should be locked in OFF state in accordance with EN60204-1.

•

After maintenance,

all wiring,

wiring ties and the like,

should be returned

to their original state and wiring route,

and the necessar

y c

learance from

all metal parts should be secured.

•

Secure a space for installation,

inspection and maintenance specified in

the manual.

Insufficient space can result in accident such as personal injur

y due to falling

from the installation place.

•

Do not install the unit in the locations listed below

.

•

Locations where carbon fiber

, metal powder or any powder is floating.

•

Locations where any substances that can affect the unit such as sulphide gas,

chloride gas,

acid and alkaline can occur

.

•

Vehicles and ships.

•

Locations where cosmetic or special sprays are often used.

•

Locations with direct exposure of oil mist and steam such as kitchen and

machine plant.

•

Locations where any machines which generate high frequency harmonics are

used.

•

Locations with salty atmospheres such as coastlines.

•

Locations with heavy snow (If installed,

be sure to provide base flame and snow

hood mentioned in the manual).

•

Locations where the unit is exposed to chimney smoke.

•

Locations at high altitude (more than 1000m high).

•

Locations with ammonic atmospheres.

•

Locations where heat radiation from other heat source can affect the unit.

•

Locations without good air circulation.

•

Locations with any obstacles which can prevent inlet and outlet air of the unit.

•

Locations where short circuit of air can occur (in case of multiple units

installation).

•

Locations where strong air blows against the air outlet of outdoor unit.

•

Locations where something located above the unit could fall.

It can cause remarkable decrease in performance,

corrosion and damage of

components,

malfunction and fire.

•

Take care when carr

ying the unit by hand.

If the unit weights more than 20kg,

it must be carried by two or more persons.

Do

not carr

y by the plastic straps,

always use the carr

y handle when carr

ying the unit

by hand.

Use gloves to minimize the risk of cuts by the aluminum fins.

•

Dispose of an

y packing materials correctly

.

Any remaining packing materials can cause personal injur

y as it contains nails and

wood.

And to avoid danger of suffocation,

be sure to keep the plastic wrapper

away from children and to dispose after tear it up.

•

Be sure to insulate the refrigerant pipes so as not to condense the

ambient air moisture on them.

Insufficient insulation can cause condensation,

which can lead to moisture

damage on the ceiling,

floor

, furniture and any other valuables.

•

When perform the air conditioner operation (cooling or dr

ying operation)

in which ventilator is installed in the room.

In this case,

using the air

conditioner in parallel with the ventilator

, there is the possibility that

drain water may backflow in accordance with the room lapse into the

negative pressure status.

Therefore,

set up the opening port such as

incorporate the air into the room that may appropriate to ventilation (For

example; Open the door a little).

In addition,

just as abo

ve,

so set up the

opening port if the room lapse into negative pressure status due to

register of the wind for the high rise apartment etc.

•

Do not install the outdoor unit in the locations listed below

.

•

Locations where discharged hot air or operating sound of the outdoor unit can

bother neighborhood.

•

Locations where outlet air of the outdoor unit blows directly to an animal or

plants.

The outlet air can affect adversely to the plant etc.

•

Locations where vibration can be amplified and transmitted due to insufficient

strength of structure.

•

Locations where vibration and operation sound generated by the outdoor unit

can affect seriously (on the wall or at the place near bed room).

•

Locations where an equipment affected by high harmonics is placed (TV set or

radio receiver is placed within 5m).

•

Locations where drainage cannot run off safely

.

It can affect surrounding environment and cause a claim.

•

Do not install the unit near the location where leakage of combustible

gases can occur

.

If leaked gases accumulate around the unit,

it can cause fire.

•

Do not install the unit where corrosive gas (such as sulfurous acid gas etc.)

or combustible gas (such as thinner and petroleum gases) can accumulate

or collect,

or where volatile combustible substances are handled.

Corrosive gas can cause corrosion of heat exchanger

, breakage of plastic parts

and etc.

And combustible gas can cause fire.

•

Do not install nor use the system c

lose to the equipment that generates

electromagnetic fields or high frequenc

y harmonics.

Equipment such as inverters,

standby generators,

medical high frequency

equipments and telecommunication equipments can affect the system,

and cause

malfunctions and breakdowns.

The system can also affect medical equipment and

telecommunication equipment,

and obstruct its function or cause jamming.

•

Do not install the outdoor unit in a location where insects and small

animals can inhabit.

Insects and small animals can enter the electric parts and cause damage or fire.

Instruct the user to keep the surroundings clean.

•

Do not use the base fl

ame for outdoor unit which is corroded or damaged

due to long periods of operation.

Using an old and damage base flame can cause the unit falling down and cause

personal injur

y.

•

Do not use an

y materials other than a fuse with the correct rating in the

location where fuses are to be used.

Connecting the circuit with copper wire or other metal thread can cause unit

failure and fire.

•

Do not touch an

y buttons with wet hands.

It can cause electric shocks.

•

Do not touch an

y refrigerant pipes with your hands when the system is in

operation.

During operation the refrigerant pipes become extremely hot or extremely cold

depending the operating condition,

and it can cause burn injur

y or frost injur

y.

•

Do not touch the suction or aluminum fin on the outdoor unit.

This may cause injur

y.

•

Do not put an

ything on the outdoor unit and operating unit.

This may cause damage the objects or injur

y due to falling to the object.

•

Do not use the unit for special purposes such as storing foods,

cooling

precision instruments and preser

vation of animals,

plants or art.

•

Do not c

lean up the unit with water

.

Notabilia as a unit designed for R410A

●

Do not use any refrigerant other than R410A.

R410A will rise to pressure about 1.6 times higher than that of aconventional refr

igerant.

A cylinder containing R410A has a pink indication mark on the top.

●

A unit designed for R410A has adopted a different size indoor unit operation valve charge port and a different size check joint

provided in the unit to prevent the charging of a wrong refrigerant by mistake.

The processed dimension of the flared part of a refrigerant pipe and a flare nut's parallel side measurement have also been alter

ed to raise strength against pressure.

Accordingly, you are required to arrange dedicated R410A tools listed in the table on the right before installing or servicing

this unit.

●

Do not use a charge cylinder. The use of acharge cylinder will cause the refrigerant composition to change, which results in pe

rformance degradation.

●

In charging refrigerant, always take it out from a cylinder in the liquid phase.

●

All indoor units must be models designed exclusively for R410A. Check connectable indoor unit models in a catalog, etc. (A wron

g indoor unit, if connected into the system, will impair proper system operation)

Summary of Contents for FDC Series

Page 95: ... 94 12 PAC T 173 Models FDT100VF 125VF 140VF H H H H H C B A F G D G PJF000Z285 ...

Page 98: ... 97 12 PAC T 173 Models FDEN60VF 71VF C 2 C 1 A B A B D C 1 C 2 C 1 C 2 E G F B PFA003Z817 ...

Page 113: ... 112 12 PAC T 173 b Wireless remote controller RCN E1R 60 17 150 Unit mm ...

Page 278: ... 277 12 PAC T 173 ー K ...

Page 346: ... 345 12 PAC T 173 Power PCB 1BSU OVNCFS 4GRNCEG VJG 2 ...

Page 518: ... 517 12 PAC T 173 3 5 SUPER LINK E BOARD SC ADNA E F SL2NA E and SL3N AE BE to control ...

Page 519: ... 518 12 PAC T 173 ...