-

267

-

'12 • PAC-T-173

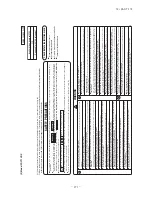

2. REFRIGERANT PIPING WORK

1)

Restrictions on unit installation and use

●

Check the following points in light of the indoor unit specifications and the installation site.

●

Observe the following restrictions on unit installation and use.

Improper installation can result in a compressor failure or per

formance degradation

.

2)

Determination of pipe size

●

Determine refrigerant pipe size pursuant to the following guidelines based on the

indoor unit specifications.

30m or less

20m or less

20m or less

L

H

H

Gas pipe

Liquid pipe

Ǿ

12.7

Ǿ

6.35

Flare

Flare

Ǿ

12.7

Ǿ

6.35

Ǿ

12.7

Ǿ

6.35

L

H

Outdoor unit

Indoor unit

CAUTION

●

The use restrictions appearing in the table above are applicable to the standard pipe size combinations shown in the table belo

w.

Where

an

exi

sti

ng pi

pe

sy

stem

is

util

iz

ed

, differ

ent

on

e-w

aypi

pe

le

ng

th

re

st

ri

cti

ons

sh

ou

ld

ap

pl

y

depending

on

its

pi

pe

si

ze

.

Fo

r

more

in

formati

on

,

pl

eas

e

se

e “5.

UTILI

ZAT

ION OF

EXISTI

NG PI

PIN

G.”

Restrictions

Dimensional restrictions

Marks appearing in the drawing on the right

Main pipe length

When the outdoor unit is positioned higher,

When the outdoor unit is positioned lower,

Elevation difference between

indoor and outdoor units

Outdoor unit connected

Refrigerant piping (branch pipeL)

Indoor unit connected

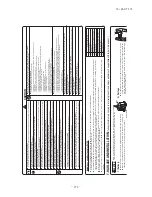

Plug the end of the pipe with tape, or other

material, and fill the pipe with nitrogen gas.

Only use nitrogen gas (N

2

)

Taping

<

N

2

>

Nitrogen

Brazing

Station valve

Primary side

Secondary side

0.5MPa

Hand

Relief valve

Nitrogen

gas

Brazing

must

be

performed

under

a

nitrogen

gas

flo

w

.

Without nitrogen gas, a large quantity of foreign matters (oxidizedfilm) are created,

causing a critical failure from capillary tube or expansion valve clogging.

About brazing

When pipe is brazing.

Model 40, 50, 60

Take

care

so

that

installed

pipes

may

not

touch

components

within

a

unit.

If

touching

with

an

internal

component

,

it

will

generate

abnormal

sounds

and/or

vibrations.

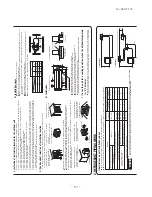

4) On-site piping work

IMPOR

TANT

How to remove the side cover

●

Carr

y

out

the

on

site

piping

work

with

the

operation

valve

fully

closed.

●

Give sufficient protection to a pipe end (compressed and blazed, or with an adhesive tape) so

that

water

or

foreign

matters

may

not

enter

the

piping.

●

Bend a pipe to a radius as large as practical.(R100~R150) Do not bend a pipe repeatedly to correct

its

form.

●

●

Flare

connection

is

used

between

the

unit

and

refrigerant

pipe.

Flare

a

pipe

after

engaging

a

The pipe should be anchored every 1.5m or less to isolate the vibration.

flare nut onto it. Flare dimensions for R410A are different from those for conventional R407C.

Although we recommend the use of flaring tools designed specifically for R410A, conventional

flaring tools can also be used by adjusting the measurement of protrusion B with a protrusion

control

gauge.

●

Tighten a flare joint securely with a double spanner

.

Please

remove

the

screw

of

a

side

cover

and

remove

to

the

front.

A

B

Flared

pipe

end

:

A

(mm)

Ǿ

6.35

Ǿ

12.7

Copper

pipe

outer

diameter

0

ー

0

.

4

A

9

.

1

16.6

Copper

pipe

protrusion

for

flaring

:

B

(mm)

Ǿ

6.35

Ǿ

12.7

Copper

pipe

outer

diameter

In

the

case

of

a

rigid

(clutch)

type

With

an

R410A

tool

With

a

conventional

tool

0

〜

0.5

1.0

〜

1.5

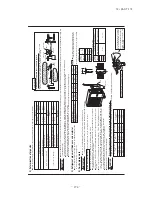

CAUTION

Do

not

apply

force

beyond

proper

fastening

torque

in

tightening

the

flare

nut.

Fix both liquid and gas operation valves at the valve main bodies as illustrated on the right, and then fasten them,

applying appropriate fastening torque.

Tightening angle (

°

)

Tightening torque (N

㨯

m)

Ǿ

6.35 (1/4")

Ǿ

12.7 (1/2")

14

〜

18

49

〜

61

45

〜

60

30

〜

45

150

250

Recommended length of a tool handle (mm)

Operation valve size (mm)

Use a torque wrench. If a torque wrench is

not available, fasten the flare nut manually

first and then tighten it further, using the

left table as a guide.

Do

not hold the valve

cap area

with

a spanner

.

3)

Refrigerant

pipe

wall

thickness

and

material

●

Select

refrigerant

pipes

of

the

table

shown

on

the

right

wall

thickness

and

material

as

specified

for

each

pipe

size.

Pipe diameter [mm]

Minimum pipe wall thickness [mm]

Pipe material*

6.35

0.8

O-type pipe

12.7

0.8

O-type pipe

*Phosphorus deoxidized seamless copper pipe ICS 23.040.15, ICS 77.150.30

NOTE

●

Select

pipes

having

a

wall

thickness

larger

than

the

specified

minimum

pipe

thickness.

Side cover

The screw of the side cover

is tightened securely.

Summary of Contents for FDC Series

Page 95: ... 94 12 PAC T 173 Models FDT100VF 125VF 140VF H H H H H C B A F G D G PJF000Z285 ...

Page 98: ... 97 12 PAC T 173 Models FDEN60VF 71VF C 2 C 1 A B A B D C 1 C 2 C 1 C 2 E G F B PFA003Z817 ...

Page 113: ... 112 12 PAC T 173 b Wireless remote controller RCN E1R 60 17 150 Unit mm ...

Page 278: ... 277 12 PAC T 173 ー K ...

Page 346: ... 345 12 PAC T 173 Power PCB 1BSU OVNCFS 4GRNCEG VJG 2 ...

Page 518: ... 517 12 PAC T 173 3 5 SUPER LINK E BOARD SC ADNA E F SL2NA E and SL3N AE BE to control ...

Page 519: ... 518 12 PAC T 173 ...