-

268

-

'12 • PAC-T-173

Wires for connecting indoor

and outdoor units

Exterior tape

Gas piping

Insulation

Liquid piping

Band (accessor

y)

Pipe cover (accessor

y)

Formula to calculate the volume of additional refrigerant required

7)

Additional

refrigerant

charge

Additional charge volume (kg) = { Main length (m) – Factor

y charged volume 15 (m) } x 0.02 (kg/m)

*When

an

additional

charge

volume

calculation

result

is

negative,

it

is

not

necessar

y

to

charge

refrigerant

additionally

.

8) Heating and condensation prevention

(1) Dress refrigerant pipes (both gas and liquid pipes) for heat insulation and prevention of dew condensation.

㨯

Improper

heat

insulation/anti-dew

dressing

can

result

in

a

w

ater

leak

or

dripping

causing

damage

to

household

effects,

etc.

(2) Use a heat insulating material that can withstand 120

℃

or a higher temperature. Poor heat insulating capacity can cause heat insulation problems or cable

deterioration.

㨯

All

gas

pipes

must

be

securely

heat

insulated

in

order

to

prevent

damage

from

dripping

water

that

comes

from

the

condensation

formed

on

them

during

a

coo

ling

operation

or

personal

injur

y

from

burns

because

their

sur

face

can

reach

quite

a

high

temperature

due

to

discharged

gas

flowing

inside

during

a

heating

operation.

㨯

Wrap

indoor

units’

flare

joints

with

heat

insulating

parts

(pipe

cover)

for

heat

insulation

(both

gas

and

liquid

pipes).

㨯

Give

heat

insulation

to

both

gas

and

liquid

side

pipes. Bundle

a

heat

insulating

material

and

a

pipe

tightly

together

so

that

no

gaps

may

b

e

left

betwee

n

them

and

wrap

them

together

with

a

connecting

cable

by

a

dressing

tape.

㨯

Both

gas

and

liquid

pipes

need

to

be

dressed

with

20

mm

or

thicker

heat

insulation

materials

above

the

ceiling

where

relative

humidity

exceeds

70%.

●

For an installation measuring 15 m or shorter in pipe length, please charge the refrigerant volume charged for shipment at the

factor

y,

when you recharge refrigerant after ser

vicing etc.

5) Air tightness test

①

Although

outdoor

and

indoor

units

themselves

have

been

tested

for

air

tightness

at

the

factor

y,

check

the

connecting

pipes

after

the

installation

wor

k

for

air

tightness

from

the

operation valve’

s check joint equipped on the outdoor unit side. While conducting a test, keep the operation valve shut all th

e time.

a)

Raise

the

pressure

to

0.5

MPa,

and

then

stop.

Leave

it

for

five

minutes

to

see

if

the

pressure

drops.

b)

Then

raise

the

pressure

to

1.5

MPa,

and

stop.

Leave

it

for

five

more

minutes

to

see

if

the

pressure

drops.

c)

Then

raise

the

pressure

to

the

specified

level

(4.15

MPa),

and

record

the

ambient

temperature

and

the

pressure.

d)

If

no

pressure

drop

is

obser

ved

with

an

installation

pressurized

to

the

specified

level

and

left

for

about

one

day

,

it

is

acceptable.

When

the

ambient

Temperature

fall

1

℃

,

the

pressure

also

fall

approximately

0.01

MPa.

The

pressure,

if

changed,

should

be

compensated

for

.

e)

If

a

pressure

drop

is

obser

ved

in

checking

e)

and

a)

–

d),

a

leak

exists

somewhere.

Find

a

leak

by

applying

bubble

test

liquid

to

welded

parts

and

flare

joi

nts

and

repair

it.

After

repair

,

conduct

an

air

-tightness

test

again.

②

In

conducting

an

air

-tightness

test,

use

nitrogen

gas

and

pressurize

the

system

with

nitrogen

gas

from

the

gas

side.

Do

not

use

a

medium

other

than

nitro

gen

gas

under

any

cir

cumstances.

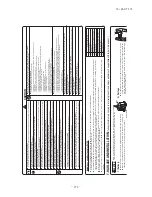

Gas side operation valve

Check joint

Pressurize

Close

Outdoor unit

Indoor unit

<

W

ork flow

>

6) Evacuation

Airtighteness test completed

Fill refrigerant

Vacuum gauge check

Vacuuming

completed

Vacuuming begins

Run

the

vacuum

pump

for

at

least

one

hour

after

the

vacuum

gauge

shows

-101kPa

or

lower

.

(-755mmHg

or

lower)

Confirm

that

the

vacuum

gauge

indicator

does

not

rise

even

if

the system is left for one hour or more.

When

the

system

has

remaining

moisture

inside

or

a

leaky

point,

the

vacuum

gauge

indicator

will

rise.

Check

the

system

for

a

leaky

point

and

then

draw

air

to

create

a

vacuum

again.

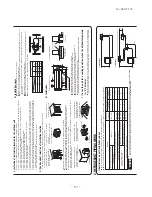

(1)

Calculate

a

required

refrigerant

charge

volume

from

the

following

table.

●

This unit contains factory charged refrigerant covering 15m of refrigerant piping and additional refrigerant charge on the

installation site is not required for an installation with up to 15m refrigerant piping.

When refrigerant piping exceeds 15m, additionally charge an amount calculated from the pipe length and the above table

for the portion in excess of 15m.

●

If an existing pipe system is used, a required refrigerant charge volume will vary depending on the liquid pipe size.

For further information, please see “5. UTILIZATION OF EXISTING PIPING.”

0.02

1.50

15

Model 40, 50, 60

Additional charge volume (kg)

per meter of refrigerant piping

(liquid pipe

Ǿ

6.35)

Refrigerant volume charged

for shipment at the factor

y

(kg)

Installation’

s pipe length (m)

covered without additional

refrigerant charge

NOTE

Put down the refrigerant volume calculated from the pipe length onto the caution label attached on

the back side of the service panel.

(2)

Charging refrigerant

●

Since R410A refrigerant must be charged in the liquid phase, you should charge it, keeping the container

cylinder upside down or using a refrigerant cylinder equipped with a siphon tube.

●

Charge refrigerant always from the liquid side service port with the operation valve shut. When you find it

difficult to charge a required amount, fully open the outdoor unit valves on both liquid and gas sides and

charge refrigerant from the gas (suction) side service port, while running the unit in the cooling mode. In

doing so, care must be taken so that refrigerant may be discharged from the cylinder in the liquid phase all

the time.

When the cylinder valve is throttled down or a dedicated conversion tool to change liquid-phase

refrigerant into mist is used to protect the compressor, however, adjust charge conditions so that

refrigerant will

gasify upon entering the unit.

●

In charging refrigerant, always charge a calculated volume by using a scale to measure the charge volume.

●

When refrigerant is charged with the unit being run, complete a charge operation within 30 minutes.

Running the unit with an insufficient quantity of refrigerant for a long time can cause a compressor failure.

Pay

attention

to

the

following

points

in

addition

to

the

above

for

the

R410A

and

compatible machines.

○

To prevent a different oil from entering, assign dedicated tools, etc. to each refrigerant

type. Under no circumstances must a

gauge manifold and a charge hose in particular be shared with other refrigerant types (R22, R407C, etc.).

○

Use a counterflow prevention adapter to prevent vacuum pump oil from entering the

refrigerant

system.

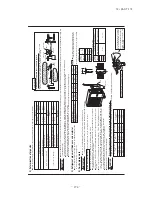

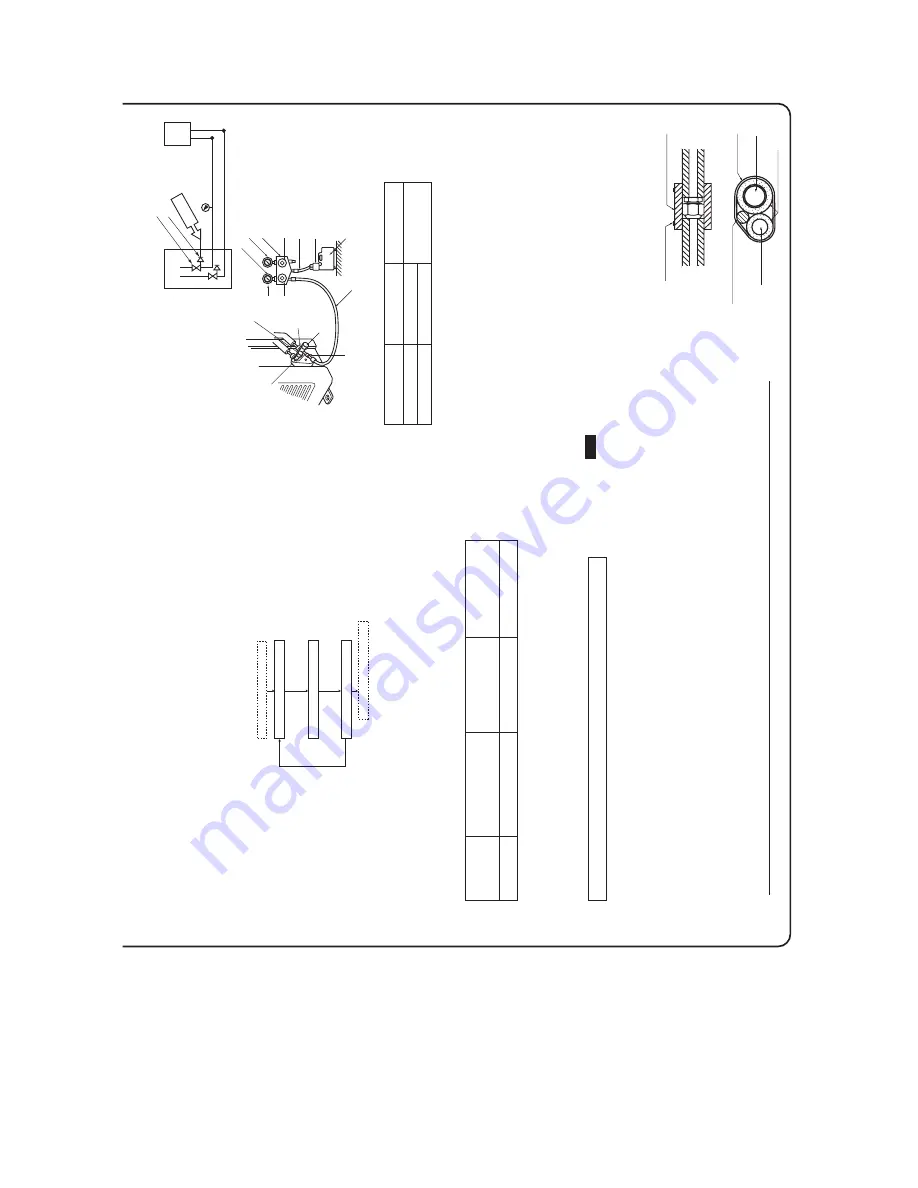

(three-way valve)

Charge hose

(Designed specifically for R410A)

Compound pressure gauge

Pressure gauge

Gauge Manifold

(Designed specifically for R410A)

Handle Hi.

Vacuum pump

Vacuum pump ada

pter

(Anti-reverse flo

w type)

(Designed specifically for R410A)

Charge hose

(Designed specifically for R410A)

Check joint

-0.1MP

a

(-76cmHg)

Handle Lo

Opera

tion V

alve

Opera

tion

Valve

(two-way valve)

Opera

tion V

alve

Ca

p

Opera

tion V

alve

Ca

p

tightening torque (N·m)

Opera

tion valve ca

p

tightening torque (N·m)

Check joint blind nut

φ

6.35 (1/4")

φ

12.7

(1/2")

20

〜

30

10

〜

12

25

〜

35

Opera

tion valve size

(mm)

Securely tighten the opera

tion valve ca

p and the check joint blind nut after adjustment.

Summary of Contents for FDC Series

Page 95: ... 94 12 PAC T 173 Models FDT100VF 125VF 140VF H H H H H C B A F G D G PJF000Z285 ...

Page 98: ... 97 12 PAC T 173 Models FDEN60VF 71VF C 2 C 1 A B A B D C 1 C 2 C 1 C 2 E G F B PFA003Z817 ...

Page 113: ... 112 12 PAC T 173 b Wireless remote controller RCN E1R 60 17 150 Unit mm ...

Page 278: ... 277 12 PAC T 173 ー K ...

Page 346: ... 345 12 PAC T 173 Power PCB 1BSU OVNCFS 4GRNCEG VJG 2 ...

Page 518: ... 517 12 PAC T 173 3 5 SUPER LINK E BOARD SC ADNA E F SL2NA E and SL3N AE BE to control ...

Page 519: ... 518 12 PAC T 173 ...