-

270

-

'12 • PAC-T-173

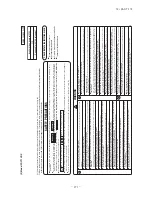

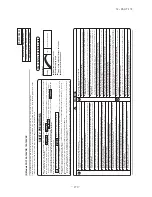

<Table

of

pipe

size

restrictions>

◎:

Standard

pipe

size

○:

Usable

△:

Restricted

to

shorter

pipe

length

limits

●

Please

consult

with

our

distributor

in

the

area,

if

you

need

to

recover

refrigerant

and

charge

it

again.

●

Any

combinations

of

pipe

sizes

not

listed

in

the

table

are

not

usable.

Additional charge volume (kg) = {Main pipe length (m) – Length covered without additional charge shown in the table (m)}

×

Additional charge volume per meter of pipe shown in the table (kg/m)

40

Pipe

size

50

60

Liquid pipe

ø

6.35

ø

9.52

Gas pipe

ø

12.7

ø

12.7

Usability

◎△

Maximum one-way pipe length

30

10

Length covered without additional charge

5

Usability

◎△

Maximum one-way pipe length

30

10

Length covered without additional charge

15

Usability

◎△

Maximum one-way pipe length

30

10

Length covered without additional charge

5

Additional charge volume per meter of pipe

0.02kg/m

0.06kg/m

Formula

to

calculate

additional

charge

volume

※

If

you

obtain

a

negative

figure

as

a

result

of

calculation,

no

additional

refrigerant

needs

to

be

charged.

Example)

When

an

60

is

installed

in

a

10m

long

existing

pipe

system

(liquid

Ǿ

9.52,

gas

Ǿ

12.7),

the

quantity

of

refrigerant

to

charge

additionally

should

be

(10m-5m)

x

0.06kg/m

=

0.3

kg.

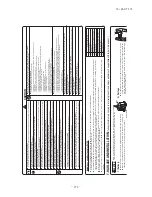

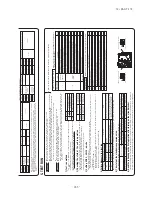

NO

Are the existing units our products?

NO

NO

NO

Is the existing pipe system to reuse free of corrosion, flaws or dents?

Repair the damaged parts.

Remove those branches.

Repair the damaged parts.

Check the pipe system for air tightness on the site.

Repair the damaged parts.

NO

NO

NO

NO

No loose pipe supports

NO

YES

ST

AR

T

The existing pipe system is reusable.

The existing pipe system is not reusable.

Install a new pipe system.

YES

YES

YES

YES

YES

Are an outdoor unit and an indoor unit connected to the

existing pipe system to reuse?

Is the unit to install in the existing pipe system a

twin-triple-double-twin model?

Is the existing pipe system to reuse free of gas leaks?

(Check whether refrigerant charge was required frequently for

the system before)

Are heat insulation materials of the existing pipe system to

reuse free of peel-offs or deterioration?

(Heat insulation is necessar

y for both gas and liquid pipes)

Change the branching pipe to a specified type.

Does the existing pipe system to reuse satisfy all of the following?

(1) The pipe length is 30m or less.

(2) The pipe size conforms to the table of pipe size restrictions.

(3) The elevation difference between the indoor and outdoor units

conforms to the following restrictions.

Where the outdoor unit is above: 15m or less

Where the outdoor unit is below: 15m or less

Which of the following refrigeration oils

does the existing unit use?

Suniso, MS, Barrel Freeze, HAB, Freol,

ether oil, ester oil

Please make an

inquir

y for

reusability

.

※

Check with the flow chart developed for a case where

an existing pipe system is reused for a

twin-triple-double-twin model published as a

technical data sheet.

Change

Change is impossible.

Can Use

Can‘t

Use

Repair

is impossible.

Air tightness is

impossible.

Remove is

impossible

Repair

is impossible.

Repair

Repair

Repair

Some loose pipe supports

Air tightness is OK

Remove

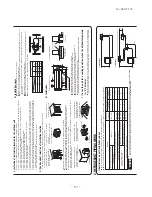

5. UTILIZA

TION OF EXISTING PIPING

Check whether an existing pipe system is reusable or not by using the following flow chart.

W

ARNING

<Where

the

existing

unit

can

be

run

for

a

cooling

operation.>

Carr

y

out

the

following

steps

with

the

excising

unit

(in

the

order

of

(1),

(2),

(3)

and

(4))

(1)

Run

the

unit

for

30

minutes

for

a

cooling

operation.

(2)

Stop

the

indoor

fan

and

run

the

unit

for

3

minutes

for

a

cooling

operation

(returning

liquid)

(3)

Close

the

liquid

side

operation

valve

of

the

outdoor

unit

and

pump

down

(refrigerant

recover

y)

(4)

Blow

with

nitrogen

gas.

※

If discolored refrigeration oil or any foreign matters is discharged

by

the

blow

,

wash

the

pipe

system

or

install

a

new

pipe

system.

●

For

the

flare

nut,

do

not

use

the

old

one,

but

use

the

one

supplied

with

the

outdoor

unit.

Process

a

flare

to

the

dimensions

specified

for

R410A.

<Where

the

existing

unit

cannot

be

run

for

a

cooling

operation.>

W

ash

the

pipe

system

or

install

a

new

pipe

system.

●

If

you

choose

to

wash

the

pipe

system,

please

contact

our

distributor

in

the

area.

Aren’t there any loose pipe supports?

Are there any branch pipes with no indoor unit connected?

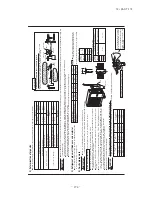

INST

ALLA

TION

TEST

CHECK

POINTS

After

installation

Check

the

following

points

again

after

completion

of

the

installation,

and

before

turnig

on

the

power

.

Conduct

a

test

run

again

and

ensure

that

the

unit

operates

properly

.

Explain

to

the

customer

how

to

use

the

unit

and

how

to

take

care

of

the

unit

following

the

instruction

manual.

Power

cables

and

connecting

wires

are

securely

fixed

to

the

terminal

block.

The

power

supply

voltage

is

correct

as

the

rating.

The

drain

hose

is

fixed

securely

.

Operational

valve

is

fully

open.

No

gas

leaks

from

the

joints

of

the

operational

valve.

The

pipe

joints

for

indoor

and

outdoor

pipes

have

been

insulated.

The

reverse

flow

check

cap

is

attached.

The

cover

of

the

pipe

cover

(A)

faces

downward

to

prevent

rain

from

entering.

Gaps

are

properly

sealed

between

the

pipe

covers

(A)

(B)

and

the

wall

sur

face

/

pipes.

The screw of the side cover is tightened securely.

15

15

15

Summary of Contents for FDC Series

Page 95: ... 94 12 PAC T 173 Models FDT100VF 125VF 140VF H H H H H C B A F G D G PJF000Z285 ...

Page 98: ... 97 12 PAC T 173 Models FDEN60VF 71VF C 2 C 1 A B A B D C 1 C 2 C 1 C 2 E G F B PFA003Z817 ...

Page 113: ... 112 12 PAC T 173 b Wireless remote controller RCN E1R 60 17 150 Unit mm ...

Page 278: ... 277 12 PAC T 173 ー K ...

Page 346: ... 345 12 PAC T 173 Power PCB 1BSU OVNCFS 4GRNCEG VJG 2 ...

Page 518: ... 517 12 PAC T 173 3 5 SUPER LINK E BOARD SC ADNA E F SL2NA E and SL3N AE BE to control ...

Page 519: ... 518 12 PAC T 173 ...