-

279

-

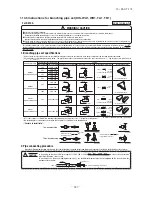

'12 • PAC-T-173

INST

ALLA

TION MANU

AL FOR OUTDOOR UNIT

SAFETY PREC

AUTIONS

PSB012D955F

Inverter driven single split P

A

C

100VNX

㨪

140VNX,100VSX

㨪

140VSX

Designed for R410A refrigerant

[ Accessor

y ]

Check before installation work

●

Model name and po

wer source

●

Refrigerant piping length

●

Piping,

wiring and miscellaneous small parts

●

Indoor unit installa

tion manual

◎

This installa

tion manual deals with outdoor units and general installa

tion specifica

tions only

. F

or indoor units,

refer to pa

ge

203.

◎

When install the unit,

be sure to check whether the selection of installa

tion place,

po

wer supply specifica

tions,

usa

ge limita

ti

on (piping length,

height

differences between indoor and outdoor units,

po

wer supply volta

ge and etc.) and installa

tion spaces

Edging

1 piece

knock-out hole protection

●

W

e

recommend you to read this

“SAFETY PRECAUTIONS”

carefully before the installa

tion work in order to gain full advanta

ge of th

e functions of the unit and to

a

void malfunction due to mishandling.

●

The precautions described belo

w are divided into and .

The ma

tters with possibilities leading

to serious consequences such as

dea

th or serious personal injur

y due to erroneous handling are listed in the and the ma

tters with possibiliti

es leading to personal injur

y or

dama

ge of the unit due to erroneous handling inc

luding probability leading to serious consequences in some cases are listed in

.

These are

ver

y important precautions for safety

. Be sure to obser

ve all of them without f

ail.

●

The meaning of "Marks" used here are as sho

wn belo

w

.

●

For 3 phase power source outdoor unit,EN61000-3-2 is not applicable if consent by the utility company or nortification to the ut

ility company is given before usage.

●

3

phase power source unit,

both indoor and outdoor

, is suitable for installa

tion in a commercial and light industrial environmen

t.

If installed as a house-hold

a

ppliance it could cause electroma

gnetic interference.

●

5 and 6 HP units of single phase po

wer source are equipment complying with IEC 61000-3-12.

●

Be sure to confirm no anomaly on the equipment by commissioning after completed installa

tion and explain the opera

ting methods a

s well as the maintenance

methods of this equipment to the user according to the o

wner's manual.

●

Keep the installa

tion manual together with o

wner's manual a

t a place where an

y user can read a

t an

y time.

Moreover if necessar

y,

ask to hand them to a new user

Never do it under an

y circumstance.

Al

ways do it according to the instruction

W

ARNING

W

ARNING

C

AUTION

C

AUTION

●

Installation must be carried out by the qualified installer

.

If you install the system by yourself,

it may cause serious trouble such as wa

ter leaks,

electric shocks,

fire and personal inju

ry

, as a result of a system

malfunction.

●

Install the system in full accordance with the instruction manual.

Incorrect installa

tion may cause bursts,

personal injur

y,

wa

ter leaks,

electric shocks and fire.

●

Use the original accessories and the specified components for installation.

If parts other than those prescribed by us are used,

It may cause fall of the unit,

wa

ter leaks,

electric shocks,

fire,

refriger

ant leak,

substandard

performance,

control failure and personal injur

y.

●

When installing in small rooms,

take prevention measures not to e

xceed the density limit of refrigerant in the event of leaka

ge

accordance with ISO5149.

Consult the expert about prevention measures.

If the density of refrigerant exceeds the limit in the event of leaka

ge,

lack of

oxygen can occur

, which

can cause serious accidents.

●

V

entilate the working area well in the event of refrigerant leakage during installation.

If the refrigerant comes into contact with naked flames,

poisonous gas is produced.

●

After completed installation,

check that no refrigerant leaks from the system.

If refrigerant leaks into the room and comes into contact with an oven or other hot surface,

poisonous gas is produced.

●

Hang up the unit at the specified points with ropes which can support the weight in lifting for portage.

And to avoid jolting ou

t of alignment,

be sure to hang up the unit at 4-point support.

An improper manner of porta

ge such as 3-point support can cause dea

th or serious personal injur

y due to falling of the unit

●

Install the unit in a location with good support.

Unsuitable installa

tion loca

tions can cause the unit to fall and cause ma

terial dama

ge and personal injur

y.

●

Ensure the unit is stable when installed,

so that it can withstand earthquakes and strong winds.

Unsuitable installa

tion loca

tions can cause the unit to fall and cause ma

terial dama

ge and personal injur

y.

●

The electrical installation must be carried out by the qualified electrician in accordance with

“the norm for electrical work”

a

nd “national

wiring regulation”,

and the system must be connected to the dedicated circuit.

P

o

wer supply with insufficient ca

pacity and incorrect function done by improper work can cause electric shocks and fire,

●

Be sure to shut off the power before starting electrical work.

Failure to shut off the po

wer can cause electric shocks,

unit failure or incorrect function of equipment.

●

Be sure to use the cables conformed to safety standard and cable ampacity for power distribution work.

Unconformable cables can cause electric leak,

anomalous hea

t production or fire.

●

Use the prescribed cables for electrical connection,

tighten the cables securely in terminal block and relieve the cables corre

ctly to prevent

o

verloading the terminal blocks.

Loose connections or cable mountings can cause anomalous hea

t production or fire.

●

Arrange the wiring in the control box so that it cannot be pushed up further into the box.

Install the ser

vice panel correctly

.

Incorrect installa

tion may result in overhea

ting and fire.

●

Do not perform brazing work in the airtight room

It can cause lack of oxygen.

●

Use the prescribed pipes,

fl

are nuts and tools for R410A.

Using existing parts (for R22 or R407C) can cause the unit failure and serious accidents due to burst of the refrigerant circui

t.

●

T

ighten the fl

are nut by using double spanners and tor

que wrench according to prescribed method.

Be sure not to

tighten the fl

are nut too much.

Loose flare connection or dama

ge on the flare part by tightening with excess torque can cause burst or refrigerant leaks which

may result in lack of oxygen.

●

Do not open the ser

vice v

alves for liquid line and gas line until completed refrigerant piping work,

air tightness test

and ev

acuation.

If the compressor is opera

ted in sta

te of opening ser

vice valves before completed connection of refrigerant piping work,

you

may incur frost bite or injur

y from an abrupt refrigerant outflo

w and air can be sucked into refrigerant circuit,

which can caus

e

burst or personal injur

y due to anomalously high pressure in the refrigerant

●

Only use prescribed optional parts.

The installation must be carried out by the qualified installer

.

If you install the system by yourself,

it can cause serious trouble such as wa

ter leaks,

electric shocks,

fire.

●

Do not perform an

y change of protective device itself or its setup condition

The forced opera

tion by short-circuiting protective device of pressure s

witch and tempera

ture controller or the use of non

specified component can cause fire or burst.

●

Be sure to switch off the power supply in the event of installation,

inspection or ser

vicing.

If the po

wer supply is not shut off,

there is a risk of electric shocks,

unit failure or personal injur

y due to the unexpected

start of fan.

●

Consult the dealer or an e

xpert regarding remo

v

al of the unit.

Incorrect installa

tion can cause wa

ter leaks,

electric shocks or fire.

●

Stop the compressor before c

losing v

alve and disconnecting refrigerant pipes in case of pump down operation.

If disconnecting refrigerant pipes in sta

te of opening ser

vice valves before compressor stopping,

you may incur frost bite or

injur

y from an abrupt refrigerant outflo

w and air can be sucked,

which can cause burst or personal injur

y due to anomalously

high pressure in the refrigerant circuit

●

Ensure that no air enters in the refrigerant circuit when the unit is installed and remo

ved.

If air enters in the refrigerant circuit,

the pressure in the refrigerant circuit becomes too high,

which can cause burst and

personal injur

y.

●

Do not run the unit with remo

ved panels or protections

T

ouching rota

ting equipments,

hot surfaces or high volta

ge parts can cause personal injur

y due to entra

pment,

burn or electric

shocks.

●

Be sure to fix up the ser

vice panels.

Incorrect fixing can cause electric shocks or fire due to intrusion of dust or wa

ter

.

●

Do not perform an

y repairs or modifications by yourself.

Consult the dealer if the unit requires repair

.

If you repair or modify the unit,

it can cause wa

ter leaks,

electric shocks or fire.

W

ARNING

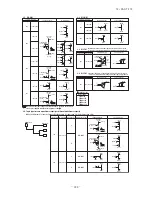

(3) Models FDC100-140VNX, 100-140VSX

Summary of Contents for FDC Series

Page 95: ... 94 12 PAC T 173 Models FDT100VF 125VF 140VF H H H H H C B A F G D G PJF000Z285 ...

Page 98: ... 97 12 PAC T 173 Models FDEN60VF 71VF C 2 C 1 A B A B D C 1 C 2 C 1 C 2 E G F B PFA003Z817 ...

Page 113: ... 112 12 PAC T 173 b Wireless remote controller RCN E1R 60 17 150 Unit mm ...

Page 278: ... 277 12 PAC T 173 ー K ...

Page 346: ... 345 12 PAC T 173 Power PCB 1BSU OVNCFS 4GRNCEG VJG 2 ...

Page 518: ... 517 12 PAC T 173 3 5 SUPER LINK E BOARD SC ADNA E F SL2NA E and SL3N AE BE to control ...

Page 519: ... 518 12 PAC T 173 ...