-

304

-

'12 • PAC-T-173

4)

In case of anomaly

a)

If any anomaly occurs on a unit in a group (a protective function operates), that unit stops with the anomalous

stop but any other normal units continue to run as they are.

b)

Signal wiring procedure

Signal wiring between indoor and outdoor units should be made on each unit same as the normal wiring.

For the group control, lay connect with sires wiring between rooms using terminal blocks (X, Y) of remote

controller.

Connect the remote controller communication wire separately from the power supply wire or wires of other

electric devices (AC220V or higher).

(18) High ceiling control

When sufficient air flow rate cannot be obtained from the indoor unit which is installed at a room with high ceiling, the air flow

rate can be increased by changing the fan tap. To change the fan tap, use the indoor unit function “FAN SPEED SET” on the

wired remote controller.

-

-

-

-

-

-

-

PHi - Hi

PHi - Me

PHi - Hi - Me

STANDARD

HIGH SPEED1, 2

FAN SPEED SET

Hi - Lo

Hi - Me

Hi - Me - Lo

PHi - PHi - Hi - Me

PHi - Hi - Me - Lo

Indoor unit airflow setting

Fan tap

Notes (1) Factory default is Standard.

(2) At the hot-start and heating thermostat OFF, or other, the indoor unit fan is operated at the low speed tap of each setting.

(3) This function is not able to be set with wireless remote controls or simple remote control (RCH-E3)

(19) Abnormal temperature thermistor (return air/indoor heat exchanger) wire/short-circuit detection

(a) Broken wire detection

When the return air temperature thermistor detects -20°C or lower or the heat exchanger temperature thermistor detect

-40°C or lower for 5 seconds continuously, the compressor stops. After a 3-minute delay, the compressor restarts but,

if it is detected again within 60 minutes after the initial detection for 6 minutes continuously, stops again (the return air

temperature thermistor: E7, the heat exchanger temperature thermistor: E6).

(b) Short-circuit detection

If the heat exchanger temperature thermistor detects 70°C or higher for 5 seconds continuously at 2 minutes and 20

seconds after the compressor ON during cooling operation, the compressor stops (E6).

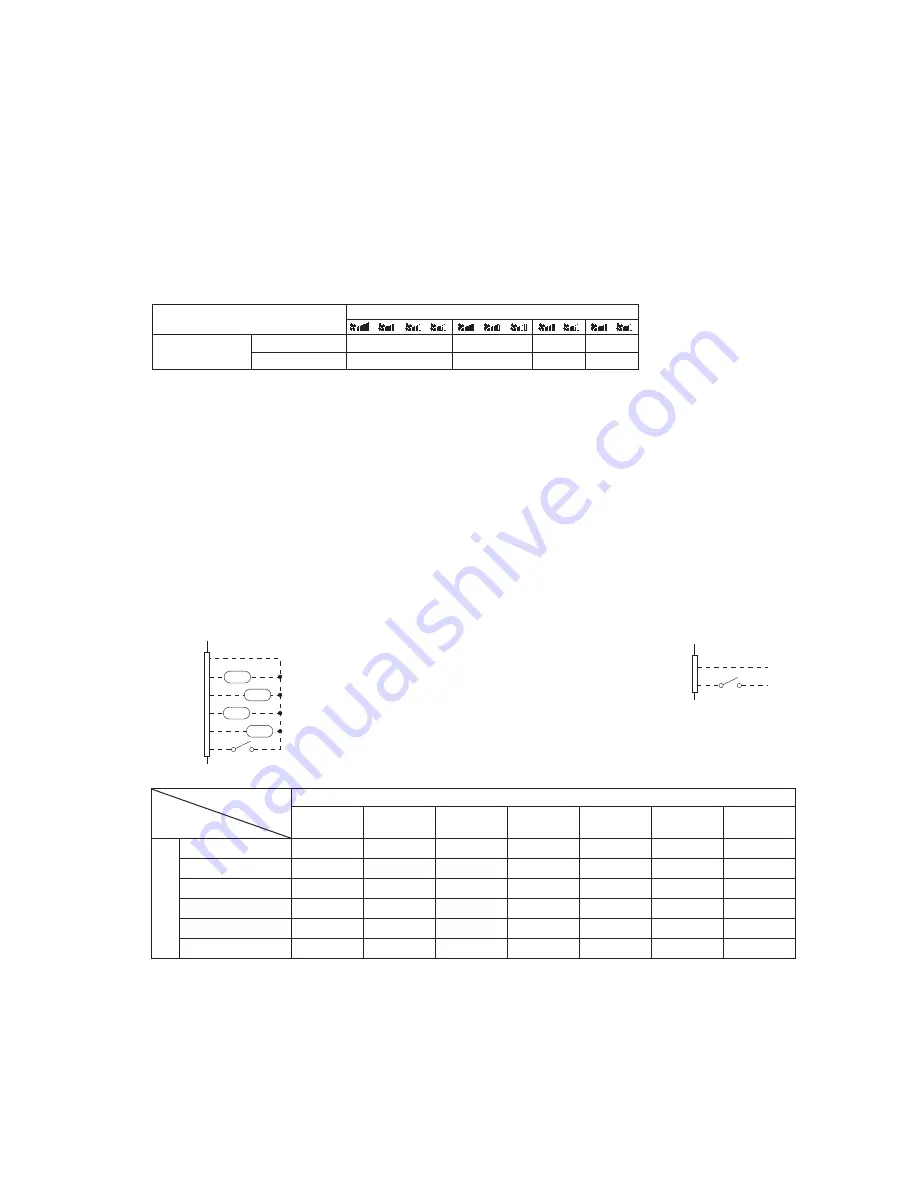

(20) External input/output control (CnT or CnTA)

Be sure to connect the wired remote controller to the indoor unit. Without wired remote controller remote operation by CnT is

not possible to perform.

・

All model

・

FDT, FDUM only

①

Operation output

(CnT-2: XR1)

②

Heating output

(CnT-3: XR2)

③

Thermostat ON output

(CnT-4: XR3)

④

Error output

(CnT-5: XR4)

⑤

Remote operation input

(CnT-6: Volt-free contact)

XR1

1

2

3

4

5

6

XR3

XR4

CnT

Blue

12V

XR2

Option

XR5

■

Priority order for combinations of CnT and CnTA input.

Note (1) Following operation commands are accepted when the operation prohibition is set with CnTA as indicated with *.

Individual operation command from remote controller, test run command from outdoor unit and operation command from optional device, CNT in put.

Reference: Explanation on the codes and the combinations of codes in the table above

1.

In case of CnT “Number”, the CnT “Number” is adopted and CnTA is invalidated.

2.

In case of CnTA “Number”, the CnTA “Number” is adopted and CnT is invalidated.

3.

In case of CnT “Number”/CnTA “Number”, the CnT “Number” and the CnTA “Number” become independent functions each other.

4.

In case of CnT “Number” + CnTA “Number”, the CnT “Number” and the CnTA “Number” become competing functions each other.

5.

In case of CnT “Number” > CnTA “Number”, the function of CnT “Number” supersedes that of CnTA “Number”.

6.

In case of CnT “Number” < CnTA “Number”, the function of CnTA “Number” supersedes that of CnT “Number”.

(The “Number” above means

①

-

⑦

in the table.)

CnTA

Blue

12V

XR6

Note (1)

CnTA function can be

changed by RC-EX1A.

CnTA

①

Operation

stop level

②

Operation

stop pulse

③

Operation

permission/prohibition

④

Operation

permission/prohibition pulse

⑤

Cooling/heating

selection level

⑥

Cooling/heating

selection pulse

⑦

Emergency

stop

CnT

①

Operation stop level

CnT

①

CnT

①

CnT

① +

CnTA

②

CnT

①

CnT

① /

CnTA

⑤

CnT

① /

CnTA

⑥

CnT

① <

CnTA

⑦

②

Operation stop pulse

CnT

②

CnT

②

CnT

② +

CnTA

③

CnT

②

CnT

② /

CnTA

⑤

CnT

② /

CnTA

⑥

CnT

② <

CnTA

⑦

③

Operation permission/prohibition level CnT

③ >

CnTA

①

CnT

③ >

CnTA

②

CnT

③ +

CnTA

③

CnT

③

CnT

③ /

CnTA

⑤

CnT

③ /

CnTA

⑥

CnT

③ <

CnTA

⑦

④

Operation permission/prohibition pulse CnT

④

CnT

④

CnT

④ +

CnTA

③※

CnT

④

CnT

④ /

CnTA

⑤

CnT

④ /

CnTA

⑥

CnT

④ <

CnTA

⑦

⑤

Cooling/heating selection level CnT

⑤ /

CnTA

①

CnT

⑤ /

CnTA

②

CnT

⑤ /

CnTA

③

CnT

⑤ /

CnTA

④

CnT

⑤

CnT

⑤

CnT

⑤ /

CnTA

⑦

⑥

Cooling/heating selection pulse CnT

⑥ /

CnTA

①

CnT

⑥ /

CnTA

②

CnT

⑥ /

CnTA

③

CnT

⑥ /

CnTA

④

CnT

⑥

CnT

⑥

CnT

⑥ /

CnTA

⑦

Summary of Contents for FDC Series

Page 95: ... 94 12 PAC T 173 Models FDT100VF 125VF 140VF H H H H H C B A F G D G PJF000Z285 ...

Page 98: ... 97 12 PAC T 173 Models FDEN60VF 71VF C 2 C 1 A B A B D C 1 C 2 C 1 C 2 E G F B PFA003Z817 ...

Page 113: ... 112 12 PAC T 173 b Wireless remote controller RCN E1R 60 17 150 Unit mm ...

Page 278: ... 277 12 PAC T 173 ー K ...

Page 346: ... 345 12 PAC T 173 Power PCB 1BSU OVNCFS 4GRNCEG VJG 2 ...

Page 518: ... 517 12 PAC T 173 3 5 SUPER LINK E BOARD SC ADNA E F SL2NA E and SL3N AE BE to control ...

Page 519: ... 518 12 PAC T 173 ...