-

490

-

'12 • PAC-T-173

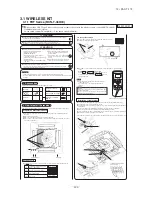

3.1 WIRELESS KIT

Pressing ACL and AIR FLOW button at the same time or

inserting the batteries with pressing AIR FLOW button will

customize the signal.

Instruct the customer how to operate it correctly referring to the instruction manual.

Accessories

Please make sure that you have all of the following accessories.

Receiver

Wireless

remote

controller

Parts set

Remote controller

holder

Wood screw for holder

AAA dry cell battery

(RO3)

<To change the settings>

②

Remove the cover by unscrewing two screws from the back of receiver.

③

Change the setting by the switch on PCB.

Screws

Receiver

Backside

Backside

Default settings

Cover

Switch

④

When SW1 is turned to OFF position, change the corresponding remote controller setting as

follows:

How to change the remote controller setting

Note

※

When the batteries are removed, the setting will return

to the default setting.

Please make sure to reset it when the batteries are

replaced.

Caution

Instruct the customer to set the mentioned above when

replacing the batteries.

(How to set is also mentioned in the user’s manual

attached on the air conditioner.)

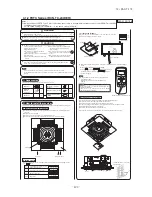

Installation of the receiver

①

Loosen the bolts which fix the panel and make a gap between the panel and the indoor unit

②

Put the wiring of the receiver through the opening.

③

Put the wiring on the notch on the control box so as not to be pinched by the control box and lid as

shown

below.

④

Connect the wiring to the terminal block provided in the control box. (Non- polarized)

⑤

Attach the receiver to the panel according to the panel installation manual.

⑥

Fix the wiring with the clamp so that the wiring do not contact the edge of control box’s metal sheet.

⑦

Reattach the control box lid with 3 screws removed.

※

Note: Make sure the wires not to be pinched by any other parts like panel, control box and indoor unit.

Terminal block in the indoor

unit control box

How to install the receiver

The receiver can be installed by replacing with a corner panel on the applicable decorative panel.

Preparation before installation

①

Attach the decorative panel onto the air conditioner according to the installation manual for

the panel.

②

Remove the air return grille.

③

Remove a corner panel located on the refrigerant pipes side.

④

Remove three screws and detach the cover (indicated as shadowed area) from the control

box of the air conditioner.

Setting on site

①

PCB on the receiver has the following switches to set the functions. Default setting is shown

with mark.

Customized signal setting to avoid

mixed communication

Receiver master/slave setting

Buzzer valid/Invalid

Auto restart

Normal

Remote

Master

Slave

Valid

Invalid

Valid

Invalid

Refrigerant pipes

Drain pipe

Fasten the wiring to the terminal securely and hold the cable securely so as not to apply

unexpected stress on the terminal.

Loose connection or hold will cause abnormal heat generation or fire.

●

Make sure the power supply is turned off when electric wiring work.

Otherwise, electric shock, malfunction and improper running may occur.

●

DO NOT install the wireless kit at the following places in order to avoid malfunction.

●

DO NOT leave the wireless kit without the cover.

In case the cover needs to be detached, protect the receiver with a packaging box or bag

in order to keep it away from water and dust.

(1) Places exposed to direct sunlight

(2) Places near heat devices

(3) High humidity places

(4) Hot surface or cold surface enough to

generate condensation

(5) Places exposed to oil mist or steam directly

(6) Uneven surface

(7) Places affected by the direct airflow of the

AC unit.

(8) Places where the receiver is influenced by

the fluorescent lamp (especially inverter

type) or sunlight.

(9) Places where the receiver is affected by

infrared rays of any other communication

devices

(10)Places where some object may obstruct the

communication with the remote controller

Radio interference prevention mode

WARNING

CAUTION

For the installation method of the air conditioner itself, refer to the installation manual enclosed in the

package.

Attention

3.1.1 FDT Series (RCN-T-36W-E)

PJF012D010

Notes :

Following functions of FDT Type-F indoor unit series are not able to be set with this wireless remote control (RCN-TC-36W-E).

1. Individual flap control system

2. 4-fan speed setting (P-Hi/Hi/Me/Lo)

ĺ

3-fan speed setting (Hi/Me/Lo)

Summary of Contents for FDC Series

Page 95: ... 94 12 PAC T 173 Models FDT100VF 125VF 140VF H H H H H C B A F G D G PJF000Z285 ...

Page 98: ... 97 12 PAC T 173 Models FDEN60VF 71VF C 2 C 1 A B A B D C 1 C 2 C 1 C 2 E G F B PFA003Z817 ...

Page 113: ... 112 12 PAC T 173 b Wireless remote controller RCN E1R 60 17 150 Unit mm ...

Page 278: ... 277 12 PAC T 173 ー K ...

Page 346: ... 345 12 PAC T 173 Power PCB 1BSU OVNCFS 4GRNCEG VJG 2 ...

Page 518: ... 517 12 PAC T 173 3 5 SUPER LINK E BOARD SC ADNA E F SL2NA E and SL3N AE BE to control ...

Page 519: ... 518 12 PAC T 173 ...