-

510

-

'12 • PAC-T-173

Step 11

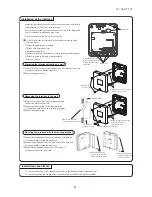

11. Reassemble the fan blade.

Take care to align the D-cut of motor shaft and the fan blade.

mark on the center of the fan shows the position of D-cut.

<Note>

1. Tightening torque of the nut is 4.0-4.9 N·m.

2. Do not rotate the axis of fan motor when tightening the nut.

It may cause malfunction of the fan motor.

Step 10

10.Insert the connector to the port (Model A:

CNN, Model B,C:CNF) on the PCB, and fix

the wire with bands. Excess part of the

wire should be dropped naturally.

<Note>

Be sure to cut the excess part of plastic band.

It may cause abnormal noise when hit by fan blade or misassembling of panels.

Do not bundle excess part of the wire. It may damage the heater.

<Note>

This heater should have bending radius of at least 25mm including non-heating part. Do not bundle the excess part of the wire. It may cause

disconnection of the heater or insufficient capacity.

Be sure to prevent the heater from touching any refrigerant piping.

Especially, pay close attention not to make it touch with pipes which are close to the wiring route such as suction pipe, check valve and check joint.

Model A

Model B

Model C

Connector CNN

(Yellow)

Band

Band

Connector CnF

(Black)

Connector CnF

(Black)

Connector CnF

(Black)

Summary of Contents for FDC Series

Page 95: ... 94 12 PAC T 173 Models FDT100VF 125VF 140VF H H H H H C B A F G D G PJF000Z285 ...

Page 98: ... 97 12 PAC T 173 Models FDEN60VF 71VF C 2 C 1 A B A B D C 1 C 2 C 1 C 2 E G F B PFA003Z817 ...

Page 113: ... 112 12 PAC T 173 b Wireless remote controller RCN E1R 60 17 150 Unit mm ...

Page 278: ... 277 12 PAC T 173 ー K ...

Page 346: ... 345 12 PAC T 173 Power PCB 1BSU OVNCFS 4GRNCEG VJG 2 ...

Page 518: ... 517 12 PAC T 173 3 5 SUPER LINK E BOARD SC ADNA E F SL2NA E and SL3N AE BE to control ...

Page 519: ... 518 12 PAC T 173 ...