'14 • KX-SM-200

–

129

–

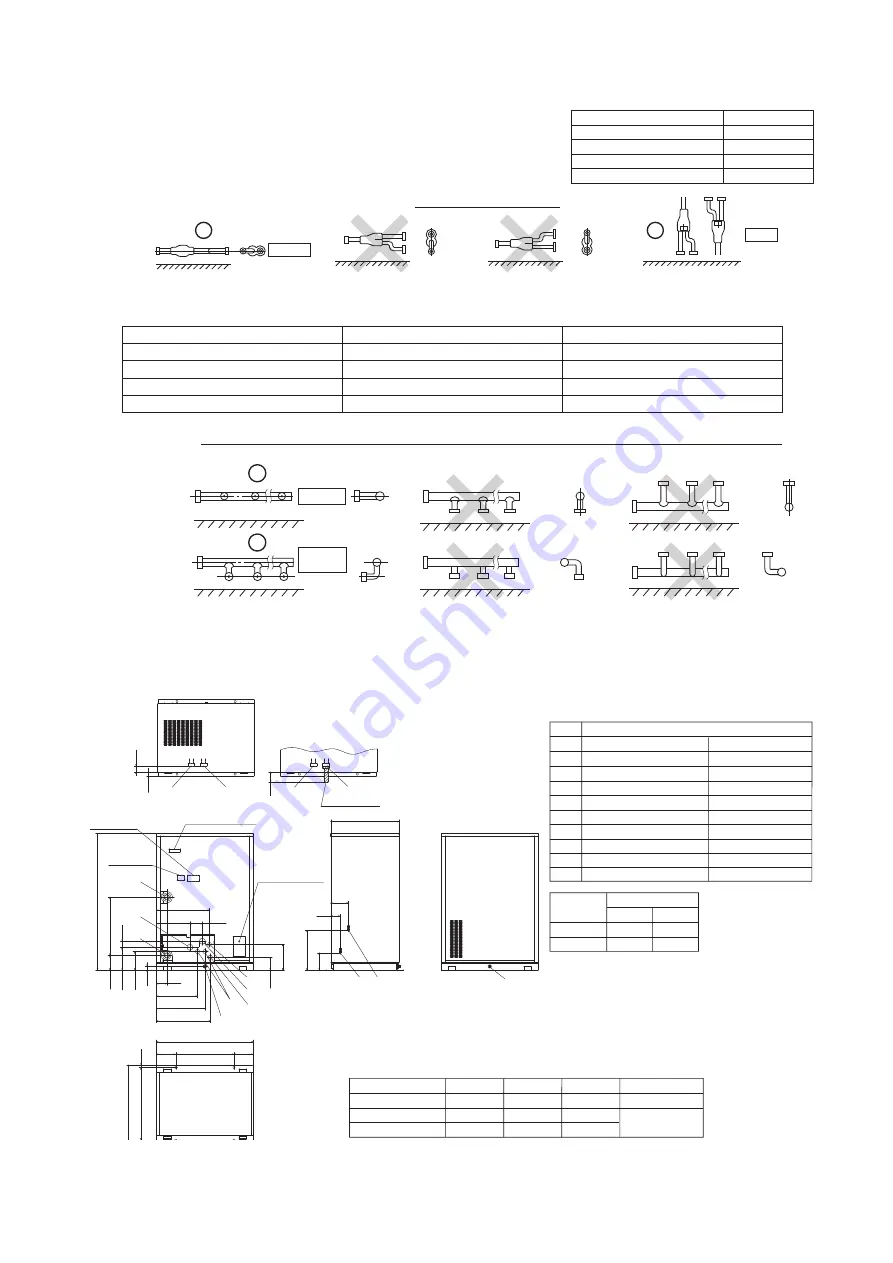

Horizontal

Floor surface

Floor surface

Floor surface

Vertical

Floor surface

Floor surface

Floor surface

downward

branch

Floor surface

Liquid side

Horizontal

Floor surface

Floor surface

Gas side

Floor surface

Dimension after

Connecting

accessory

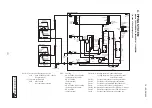

Model name label

7-segment display

Power source

connection

terminal box

Signal wire

connection

terminal box

Accessory pipe

H (Back)

550

480

270

100

84

330

390

435

780

468

156

156

80

1100

470

50

208

104

C2

139

118

183

20

584

20

624

150

30

37

50

A

B

B

A

G

C1

75

C

A

D

J,K

H (Front)

L

D

C

B

F

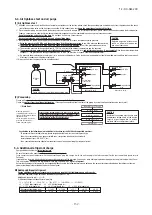

Figure 1

Indoor unit

Indoor unit

Heat source unit

Heat source unit

Heat source unit

Branching pipe set

on the indoor unit side

Model type: DIS

Branching pipe set

on the heat source unit side

Model type: DOS

Branching pipe set

on the indoor unit side

Model type: DIS

Header set on the indoor unit side

Model type: HEAD

A

A

A

E

B

C

C

C

C

D

D

D

D

D

D

D

D

Please note

a) In connecting a heat source unit, please use a pipe conforming to the pipe size specified for heat source unit connection.

b) For pipes connected to the indoor unit (= main pipes), use the pipe size specified above.

c) Always install branching pipes (for both gas and liquid) in such a manner that they form either correct horizontial or vertical branch.

(4) Selection of a heat source unit side branching pipe set

This branching pipe set will always become necessary when units are used in combination.

(When a unit is used as a standalone installation, it is not required)

Heat source unit

For two units (for 450 – 670)

For three units (for 730 – 1000)

Branching pipe set

DOS-2A-3

DOS-3A-3

Please use C1220T-1/2H for

φ

19.05 or larger pipes.

(e) Indoor unit side branching pipe – Indoor unit: Section D in Figure 1

Indoor unit connection pipe size table

Capacity

15, 22, 28

36, 45, 56

71, 90, 112, 140, 160

224

280

Gas pipe

φ

9.52

×

t 0.8

φ

12.7

×

t 0.8

φ

15.88

×

t 1.0

φ

19.05

×

t 1.0

φ

22.22

×

t 1.0

Liquid pipe

φ

6.35

×

t 0.8

φ

9.52

×

t 0.8

Indoor unit

Please use C1220T-1/2H for

φ

19.05 or larger pipes.

(b) Selection of the connection pipe to branching pipes for three heat source units combination:

Section E in Figure 1

Total capacity of heat source units connected

to second branch pipe heat source unit side

Pipe size between branching pipes

450, 500, 560, 615, 670

Gas pipe

φ

28.58

×

t 1.0

Liquid pipe

φ

12.7

×

t 0.8

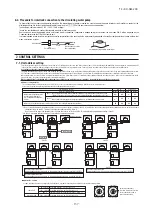

5-2. Pipe connection position and pipe direction

Total capacity downstream

Less than 180

180 or more but less than 371

371 or more but less than 540

540 or more

Branching pipe set

DIS-22-1G

DIS-180-1G

DIS-371-1G

DIS-540-3

Total capacity downstream

Less than 180

180 or more but less than 371

371 or more but less than 540

540 or more

Header set model type

HEAD4-22-1G

HEAD6-180-1G

HEAD8-371-2

HEAD8-540-3

Number of branches

4 branches at the most

6 branches at the most

8 branches at the most

8 branches at the most

(5) Selection of an indoor unit side branching pipe set

(a) Method of selecting a branching pipe set

●

As an appropriate branching pipe size varies with the connected capacity (total capacity connected

downstream), determine a size from the following table.

Please note

a) In connecting an indoor unit with the indoor unit side branching pipe set, please use a pipe

conforming to the pipe size specified for indoor unit connection.

b) Always install branching pipes (both gas and liquid pipe)

either horizontally or vertically

.

(b) Header Method

●

Depending on the number of units connected, connect plugged pipes (to be procured on the installer’s part) at a branching point (on the indoor unit connection side).

●

For the size of a plugged pipe, please refer to the documentation for a header set (option part).

Please note

a) In connecting a header with an indoor unit, please use a pipe conforming to the pipe size specified for indoor unit connection.

b)

In installing a header, always arrange a gas-side header to branch horizontally and a liquid-side header to branch downward.

c) Indoor units 224 and 280 can not be connected to the header.

Please use C1220T-1/2H for

φ

19.05 or larger pipes.

Pipe sizes applicable to European installations are shown in parentheses.

(d) Indoor unit side first branching pipe – Indoor unit side branching pipe: Section C in Figure 1

Please choose from the table below an appropriate pipe size as determined by the total capacity of indoor units connected downstream, provided,

however, that the

pipe size for this section should not exceed the main size (Section B in Figure 1).

Gas pipe

φ

12.7

×

t 1.0

φ

15.88

×

t 1.0

φ

19.05

×

t 1.0 *

φ

25.4

×

t 1.0

(

φ

28.58)

φ

28.58

×

t 1.0

φ

31.75

×

t 1.1

(

φ

34.92

×

t 1.2

)

φ

38.1

×

t 1.35

(

φ

34.92

×

t 1.2

)

Total capacity of indoor units

Less than 70

70 or more but less than 180

180 or more but less than 371

371 or more but less than 540

540 or more but less than 700

700 or more but less than 1100

1100 or more

Liquid pipe

φ

9.52

×

t 0.8

φ

12.7

×

t 0.8

φ

15.88

×

t 1.0

φ

19.05

×

t 1.0

* When connecting indoor units of 280 at the downstream and the main gas pipe is of

φ

22.22 or larger, use the pipe of

φ

22.22x t1.0.

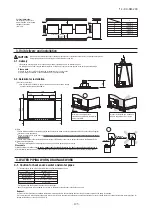

(1) Pipe connecting position and pipe outgoing direction

Please use C1220T-1/2H for

φ

19.05 or larger pipes.

*

Please connect the master and slave units with an oil equalization pipe, when they are used in a combined installation. (It is not required, when a unit is used

as a standalone installation)

When three heat source units combination, please connect using the tee joint (attached to the branching pipe set (DOS-3A-3)).

(a) Heat source unit – Heat source unit side branching pipe: Section A in Figure 1

Please use a pipe conforming to the pipe size specified for heat source unit connection.

Indoor unit connecting pipe size table

(3) Pipe size selection

Capacity

Gas pipe

224

280

335

φ

19.05

× t

1.0

φ

22.22

× t

1.0

φ

25.4 (

φ

22.22)

× t

1.0

Connection method

Flange

Liquid pipe

Heat source unit outlet pipe specifications

Connection method

Connection method

Oil equalization pipe

φ

9.52

× t

0.8

φ

12.7

× t

0.8

Flare

Flare

φ

9.52

× t

0.8

*

Pipe sizes applicable to European installations are shown in parentheses.

(1) Key consideration for water piping

Please consider following point when designing and installing. (Description of

①

-

⑦

in above figure)

①

Union joint

Be sure to fit it in order to enable the unit replacement easily.

②

Valve

Be sure to fit it for servicing such as cleaning heat exchanger and/or replacing unit and etc.

③

Drain piping

Be sure to make its descending slope as larger as possible and make the distance of its horizontal part as shorter as possible in order to prevent the drain water

from freezing.

④

Strainer

Be sure to fit a strainer (50 mesh or more) at the inlet port of the unit to avoid intrusion of foreign matter into the unit.

⑤

Air purge valve

Be sure to equip it to the place where air may accumulate in order to purge air in the water pipe.

⑥

Water piping

Water piping work shall be done by considering to purge air in the water pipe easily. Insulation work shall be done sufficiently.

⑦

Drain valve

Be sure to equip it in order to drain off the water from the system at servicing.

Select carefully a position where water can be drained completely from piping.

(2) Caution for corrosion

(a)

Water quality

It is important to check in advance whether the feed water and hot water have good quality.

Be sure to use cyclic water and makeup water whose qualities are within the range of water quality standards mentioned in Section 2-1.

(b)

Foreign matter in water

If solid matter such as sand and small stone and/or floating suspended solid such as corrosion product exist in water, the heat-transfer surface of heat exchanger is directly attacked

by water flow, and corrosion may be created locally.

In order to avoid such corrosion by these foreign matters, be sure to fit a cleanable strainer (50 mesh or higher) at the water inlet port of the unit to remove foreign matters.

(3) Others

(a)

Water pipe shall have no water leak and no air intrusion. Especially if air intrudes at suction side of pump, pump performance becomes decreasing and it may cause generation of noise

(b)

Be sure to take into consideration for water pipe not to freeze at stopping operation in winter

Height difference between

heat source units 0.4m

Height difference between

indoor units 15m

Distance between a heat

source unit and a heat source

unit side branching pipe 5m

Difference in the elevation 50m

Actual length

160m

Equivalent length

185m

Total length

510m

Indoor unit

CAUTION

An installation not conforming to these restrictions can

induce a compressor failure, which shall be excluded from

the scope of warranty. Always observe the restrictions on

the use of pipes in developing a system.

●

Total pipe length

510 m or less

●

Main pipe length

130 m or less

●

Allowable pipe length from the first branching

90 m or less

(However, difference between the longest and shortest piping

40 m or less)

●

Allowable elevation difference (head difference)

(a) When a heat source unit is installed above

50 m or less

(b) When a heat source unit is installed below

40 m or less

(c) Difference in the elevation of indoor units in a system

15 m or less

(d) Elevation difference between the first branching point and the

indoor unit

15 m or less

●

Restrictions on piping applicable to the section between a heat source unit

and a heat source unit side branching pipe (combination unit)

(a) Difference in the elevation

0.4 m or less

(b) Distance between a heat source unit and a heat source unit side branching pipe

5 m or less

(c) Length of oil equalization piping

10 m or less

●

Please use pipes clean on both the inside and outside and free from contaminants harmful to operation such as sulfur, oxides, d ust, chips, oil, fat and water.

●

Use the following material for refrigerant piping.

Material: phosphorus deoxidized seamless copper pipe (C1120T-O, 1/2H, JIS H 3300)

Use C1220T-1/2H for

φ

19.05 or larger, or C1220T-O for

φ

15.88 or smaller

●

Do not use

φ

28.58 x t1.0,

φ

31.8 x t1.1,

φ

34.92 x t1.2 and

φ

38.1 x t1.35 as a bent pipe.

●

Thickness and size: Please select proper pipes according to the pipe size selection guideline.

(Since this unit uses R410A, always use 1/2H pipes of a specified minimum thickness or thicker for all pipes of

φ

19.05 or larger, because the pressure

resistance requirement is not satisfied with O-type pipes).

●

For branching pipes, use a genuine branching pipe set or header set at all times. (optional parts)

●

For the handling of operation valves, please refer to Section 5-5.

●

In installing pipes, observe the restrictions on the use of pipes set out in this Section (1) (Maximum length, total pipe length, allowable pipe length from the first

branching, allowable elevation difference (head difference)) without fail.

●

Install a branching pipe set, paying attention to the direction of attachment, after you have perused through the installation manual supplied with it.

(2) Piping material selection

5. REFRIGERANT PIPING

●

In installing pipes, always observe the restrictions on the use of pipes specified in this Section (1) including Maximum length, Total pipe

length, Allowable pipe length from the first branching, and Allowable elevation difference (head difference)

.

●

Please avoid forming any trap ( ) or bump ( ) in piping as they can cause fluid stagnation.

●

Maximum length (from a heat source unit to the farthest indoor unit)

・・・・・・・・・

160 m or less as actual pipe length (185 m or less as equivalent pipe length)

(When an actual pipe length exceeds 90m, however, it is necessary to change the pipe size. Please determine the main pipe size by consulting with the Main

Selection Reference Table set out in this Section (3) (c).

5-1. Restrictions on the use of pipes

(1) Limitation on use of pipes

Check the connecting positions at water inlet/outlet on the outline drawing in Section 5-2(1).

Water pipe joints in this heat source unit are made of stainless steel. When a pipe made of other kind of metal is connected to the joint, use an insulating material between them to prevent

corrosion resulting from such combination of different metals.

Size of water pipe should be same or larger than the size of water pipe at the product side (R1 1/4).

To avoid from the weight of water pipes being exerted to joints of heat source unit, support the water pipes at places in the building, which are sufficiently strong.

Be sure to tighten joints between water pipes and sockets to a tightening torque not larger than 265 N

・

m.

Devices might be damaged if it is tightened with a torque larger than that.

Install an air vent valve on water pipe where air is likely trapped so that air can be bled effective when filling water in the pipeline.

Be sure to provide anti-freezing means where a risk of freezing is suspected.

When all water pipes have been connected, run the circulating water pump to confirm that there is no water leakage.

Run the circulating water pump to bleed air till water flows out from the air vent on water pipes connected at site.

Run the circulating water pump to flash in water pipes. Clean strainers after the flashing.

Since this product is designed for indoor specifications, perform the piping work with care to avoid water condensation on the control, etc.

4-3. Water pipe connection

Drain pipe joints are provided in front and rear of the heat source unit.

When the joint at the rear is used, remove the plug from the rear joint and attach it to the front joint. Tighten the plug securely.

Size of drain pipe must be same or larger than that of the drain pipe joint (Rp 1/2).

Do not connect the drain pipe to the heat source water outlet.

Incline the drain pipe downward (larger than 1/100), with care to avoid air traps.

After connecting drain pipes, confirm that they are not clogged with dirt and water runs down smoothly.

4-4. Drain pipe

Dress water pipes with heat insulation material to prevent dew condensation.

4-5. Heat insulation

4-2. Outline of water piping

Heat source unit

③

Shows the flow direction of water

Structure of water piping

④

⑦

⑤

①

①

②

②

⑥

⑥

MARK

A

B

C

D

F

G

H

J

K

L

High/low gas line

Suction gas line

*1

Liquid line

Oil equalization line

Water inlet

Water outlet

Drain outlet

Power source intake

Signal wiring intake

Anchor bolt hole

Refer to note.

Refer to note.

Refer to note.

Refer to note.

R1 1/4

R1 1/4

Rp 1/2,2pcs.

φ

35

φ

35

φ

28,4pcs.

Content

Dimension

C1

C2

224,280

142

322

335

139

316

Capacity

(Unit: mm)

High/low gas line

Liquid line

Oil equalization line

φ

19.05

φ

9.52

φ

9.52

φ

22.22

φ

9.52

φ

9.52

φ

25.4

φ

12.7

φ

9.52

*1: In case of heat pump system, not to use Suction gas line.

335

Connection method

Flange

Flare

280

224

Capacity

Note 1. Piping size is as follows.

Please use C1220T-1/2H for

φ

19.05 or larger pipes.

Pipe sizes applicable to European installations are shown in parentheses.

(c) Main (Heat source unit side branching pipe – Indoor unit side first branching pipe): Section B in Figure 1

If the longest distance (measured between the heat source unit and the farthest indoor unit) is 90m or longer (actual length), please change the main pipe size

according to the table below.

Gas pipe

Liquid pipe

Gas pipe

Liquid pipe

φ

19.05

×

t 1.0

φ

22.22

×

t 1.0

φ

25.4 (

φ

22.22)

×

t 1.0

φ28.58

×

t 1.0

φ31.75

×

t 1.1

(φ34.92

×

t 1.2)

φ38.1

×

t 1.35 (

φ34.92

×

t 1.2)

φ

22.22

×

t 1.0

φ

25.4

×

t 1.0

φ31.75

×

t 1.1

(φ28.58

×

t 1.0)

φ38.1

×

t 1.35

(φ34.92

×

t 1.2)

φ

9.52

×

t 0.8

φ

12.7

×

t 0.8

φ

15.88

×

t 1.0

φ

12.7

×

t 0.8

φ

15.88

×

t 1.0

φ

19.05

×

t 1.0

Main pipe size (normal)

Pipe size for an actual length of 90m or longer

Heat source unit

224

280

335

450

500

560

615

670

730

775

850

900

950

1000

(

φ

22.22

×

t 1.0)

Heat source unit

Heat source unit

Summary of Contents for FDC1000KXZWE1

Page 171: ... 14 KX SM 200 169 ...

Page 172: ... 14 KX SM 200 170 ...

Page 173: ... 14 KX SM 200 171 ...

Page 174: ... 14 KX SM 200 172 ...