'14 • KX-SM-200

–

148

–

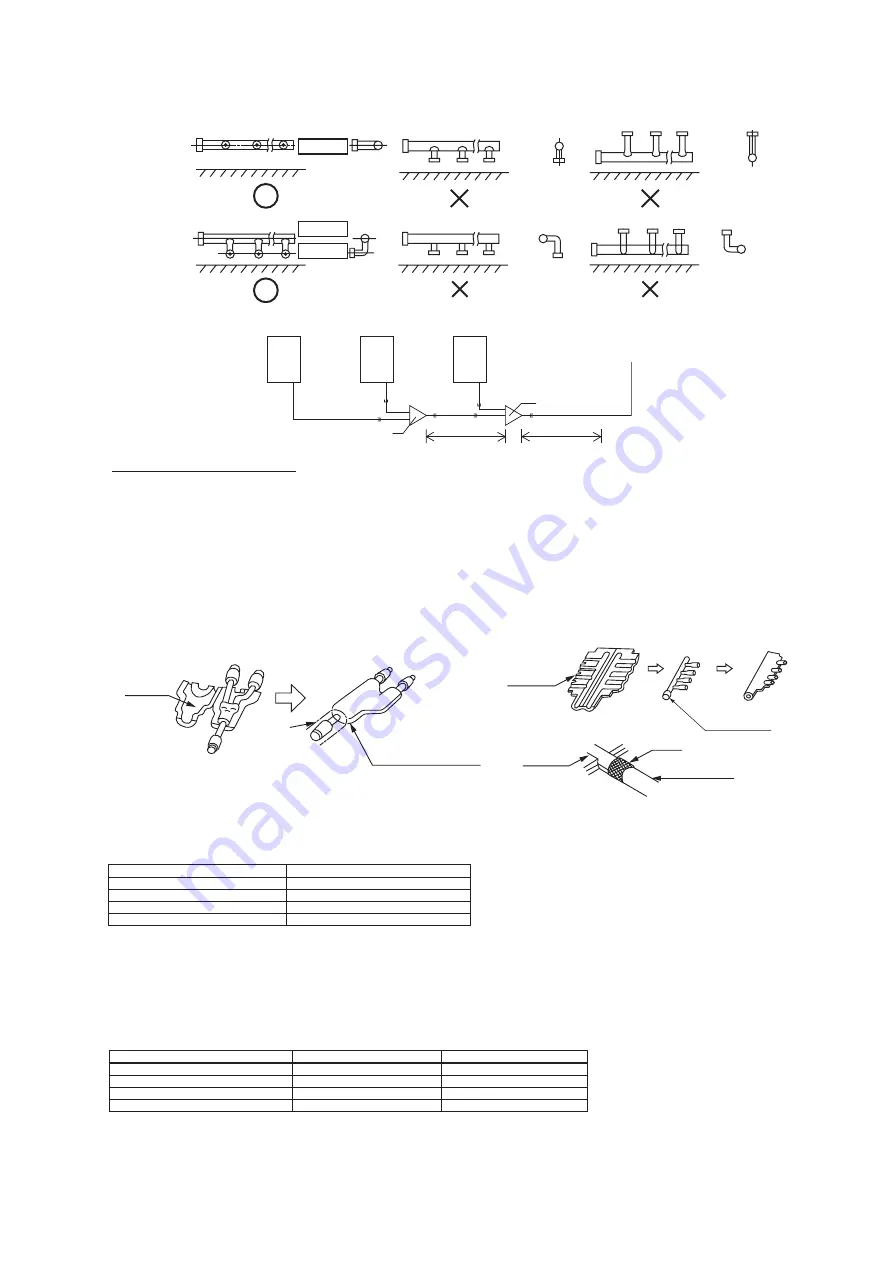

(3) Please dress it with an attached insulation sheet for heat insulation. (Please dress both liquid and gas sides)

Attention

①

A1pply an attached insulation sheet along a pipe, tape the joining line with a joint tape (to be procured on the installer's part) for complete sealing, and wrap the pipe and insulation sheet

entirely with a tape.

②

Dress both liquid and gas pipes with attached insulation sheets for heat insulation.

③

Ensure that the liquid pipe is given the heat insulation as good as that of the gas pipe. The absence of heat insulation can cause dripping water from dew condensing on the pipe or performance

degradation.

・

In the case of a header set (model type HEAD)

④

⑤

Always apply nitrogen gas when soldering joints. If nitrogen gas is not applied, a large amount of film oxide will be formed which could lead to a critical failure in the unit. Use caution to prevent

moisture or any foreign matters from entering the pipe when connecting pipe ends.

For the method of air tightness testing and pulling air, please refer to the installation manual of the heat source unit.

⑥

Do not leave piping with any open ends uncovered to prevent water or foreign matters from entering inside.

(4) How to select a branching pipe

⑴

Method to select a branch pipe set (Type DIS)

●

An appropriate branching pipe size varies depending on the capacity of connected indoor units (combined total capacity connected downstream), so please choose from the table below.

●

In the case of a 140/160 (5/6HP) outdoor unit, however, select DIS-22-1G. (Even if the capacity of connected indoor units reaches 180 or higher, select DIS-22-1G.)

Total capacity downstream

Branching pipe set model type

less than 180

DIS-22-1G

180 or higher – less than 371

DIS-180-1G

371 or higher – less than 540

DIS-371-1G

540 or more

DIS-540-3

Attention

①

Use a pipe conforming to a pipe size specified for indoor unit connection for the section between an indoor unit and an indoor unit side branching pipe.

②

A branching joint (for both gas and liquid) must always be positioned in such a way that it branches either horizontally or vertically.

⑵

How to select a header set

●

Depending on the number of units connected, connect plugged pipes (to be procured on the installer's part) at a branching point (on the indoor unit connection side).

●

For the size of a plugged pipe, please refer to the documentation for a header set (optional part).

●

In the case of a 140/160 (5/6HP) outdoor unit, however, select HEAD4-22-1G. (Even if the capacity of connected indoor units reaches 180 or higher, select HEAD4-22-1G.)

Horizontal

Horizontal

Horizontal

Floor surface

Gas side

Iiquid side

Floor surface

Floor surface

Floor surface

Floor surface

Floor surface

Adhesive

surface

Prepare

these parts

on slte.

Seal the seam and the entire

insulation with tape.

Insulation

Insulation

Tape

Gas side header

Pipes laid on sile

Insulation

280

335

335

Heat source unit 1

Heat source unit 2

Heat source unit 3

Heat source unit’s branch pipe 1

Straight pipe section 500 mm or more

Straight pipe section 500 mm or more

Heat source unit’s branch pipe 2

When using the heat source unit’s branch pipe set, make sure to secure a straight section of 500 mm or more for both the gas and liquid pipes before branching them.

Total capacity downstream

Header set model type

Number of branches

less than 180

HEAD4-22-1G

Up to 4 branches

180 or higher – less than 371

HEAD6-180-1G

Up to 6 branches

371 or higher – less than 540

HEAD8-371-2

Up to 8 branches

540 or more

HEAD8-540-3

Up to 8 branches

Attention

①

Use a pipe conforming to a pipe size specified for indoor unit connection for the section between a header and an indoor unit.

②

Always position a header (both gas and liquid headers) in such a way that it branches horizontally.

③

No 224 or 280 indoor unit is connectable to a header.

Summary of Contents for FDC1000KXZWE1

Page 171: ... 14 KX SM 200 169 ...

Page 172: ... 14 KX SM 200 170 ...

Page 173: ... 14 KX SM 200 171 ...

Page 174: ... 14 KX SM 200 172 ...