Precautions for safety

Read these "Precautions for safety" carefully before starting disassembly work and do it in the proper way.

When disassembling, be sure to turn off the power. When disassembling the electrical components, check the electrical wiring diagram.

The electrical components are under high voltage by the operation of the booster capacitor.

Fully discharge the capacitor before commencing a repair work. Failure to observe this warning could result in electric shock.

When parts of refrigerant cycle is disassembled by welding, be sure to work after collecting a refrigerant, if the refrigerant isn't

collected, the unit might explode.

Be sure to collect refrigerant without spreading it in the air.

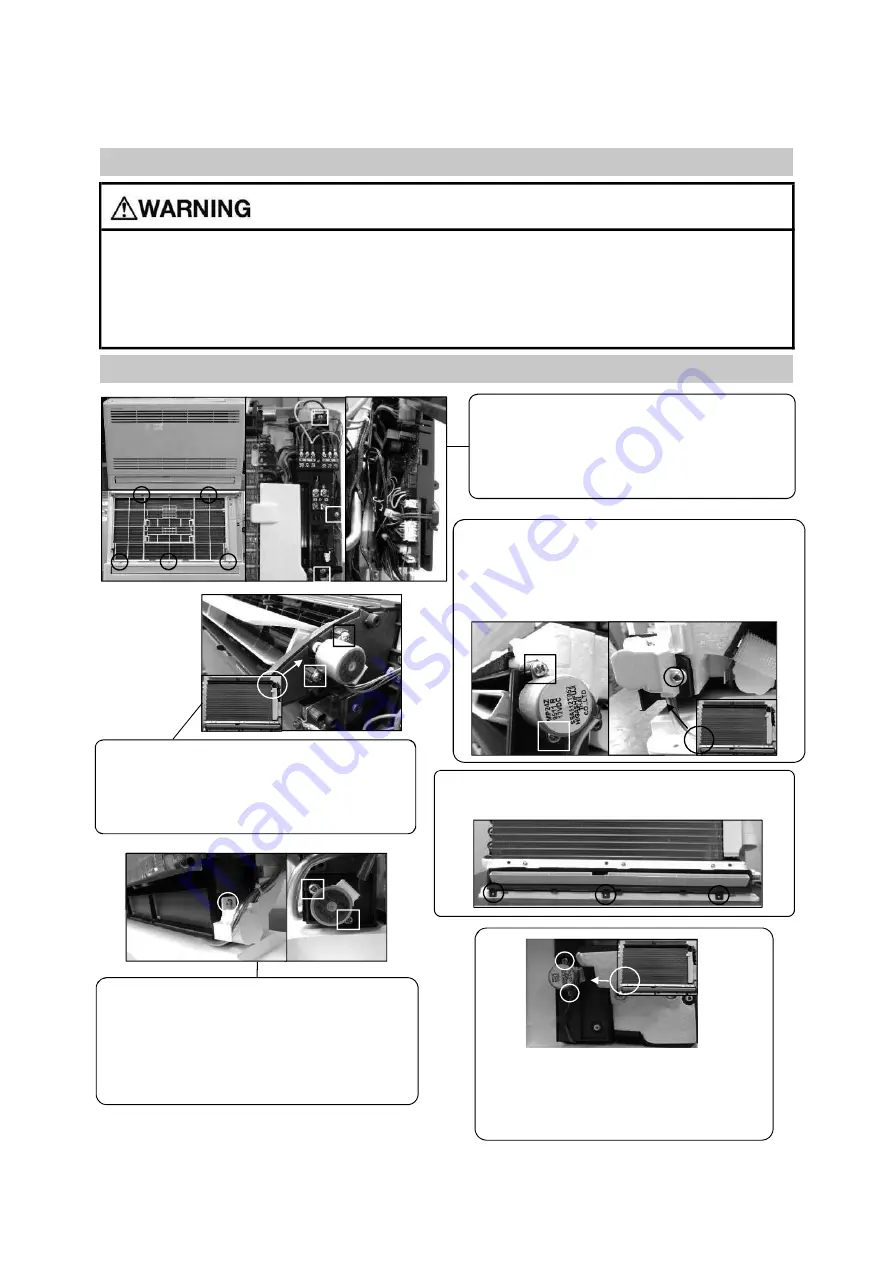

These contents are an example. Please refer to a similar part of actual unit.

1. To remove the control box

(1) Remove hooks of the front panel and remove it.

(2) Remove 5 filter assembly fixing screws and

remove it.(

mark)

(3) Remove 3 control box and lid fixing screws,

and remove it.(

mark)

(4) Pull the control box forward.

2. To remove the lower flap motor (LFM)

(1) Remove the control box.(See No.1)

(2) Disconnect the lower flap motor connector(CNJ3)

in the way of wiring.

(3) Remove the cover fixing screw and remove it.(

mark)

(4) Remove 2 lower flap motor screws and remove it.

(

mark)

3. To remove the upper flap motor (UFM)

(1) Remove the control box.(See No.1)

(2) Disconnect the upper flap motor connector(CNJ4)

4. To remove drain pan

in the way of wiring.

(1) Remove the lower flap motor.(See No.3)

(3) Remove 2 upper flap motor fixing screws and

(2) Remove 3 drain pan fixing screws and remove it.(

mark)

remove it.(

mark)

5. To remove the damper arm motor (DAM)

(1) Remove the control box.(See No.1)

(2) Disconnect the damper arm motor connector(CNJ2)

in the way of wiring.

(3) Remove the cover fixing screw and remove it.

(

mark)

6. To remove the damper motor (DM)

(4) Remove 2 damper arm motor fixing screws and

(1) Remove the control box.(See No.1)

remove it.(

mark)

(2) Disconnect the damper motor connector(CNJ1)

in the way of wiring.

(3) Remove 2 damper arm motor fixing screws and

remove it.(

mark)

DISASSEMBLY PROCEDURE

PROCEDURE & PICTURES

(FDFW series)

'14 • KX-SM-200

–

1

7

5

–

Summary of Contents for FDC1000KXZWE1

Page 171: ... 14 KX SM 200 169 ...

Page 172: ... 14 KX SM 200 170 ...

Page 173: ... 14 KX SM 200 171 ...

Page 174: ... 14 KX SM 200 172 ...